Method for designing inner mould self-setting digital controller

A digital controller, internal model controller technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of adjusting the performance of the controller parameter system, ignoring the identification method test signal design, inability to know and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

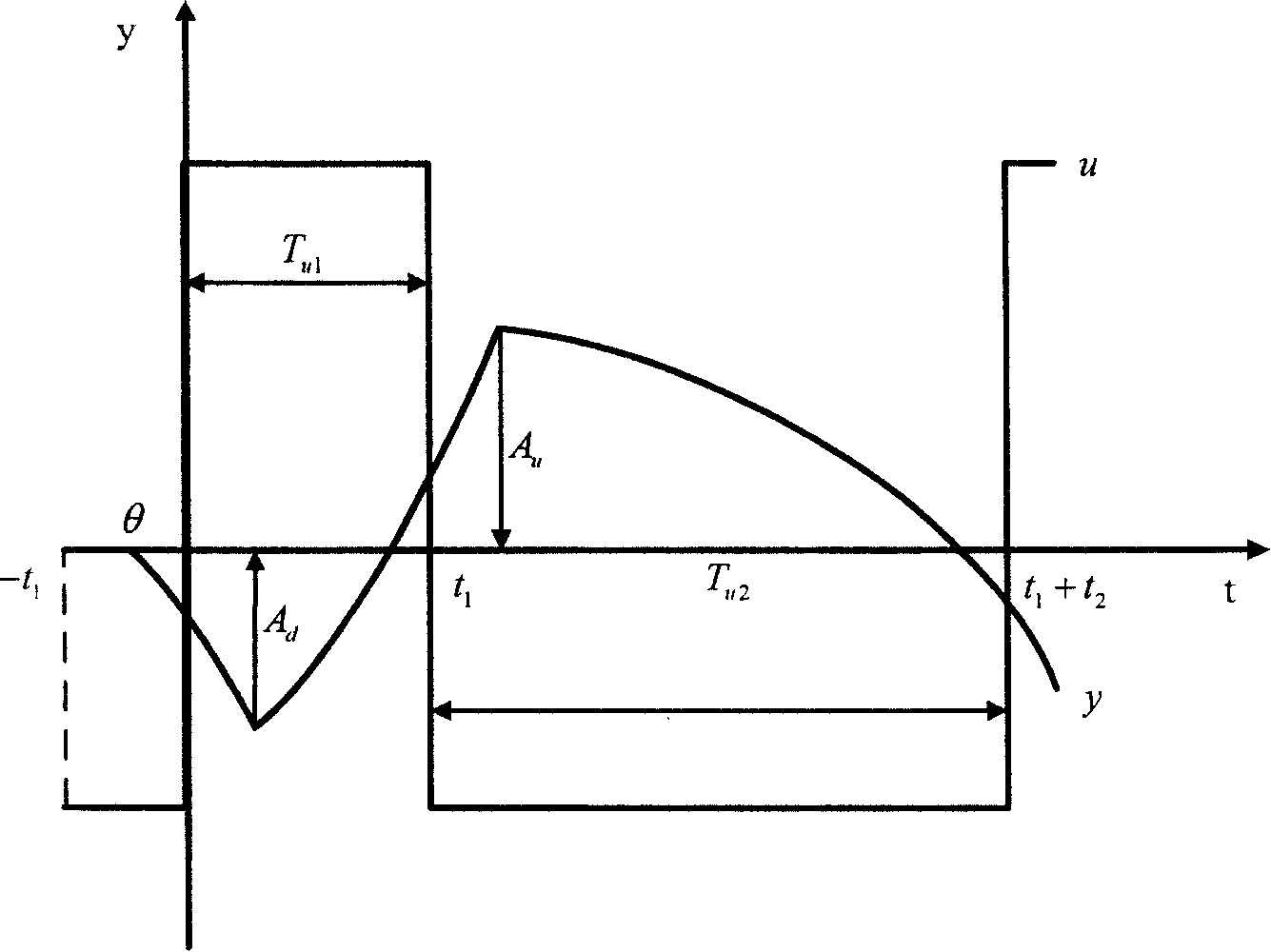

[0048] Such as figure 1 As shown, it means that under the action of the bias relay, the input signal of the object to be identified is a periodic square wave as shown in the figure, and the corresponding periodic signal is output.

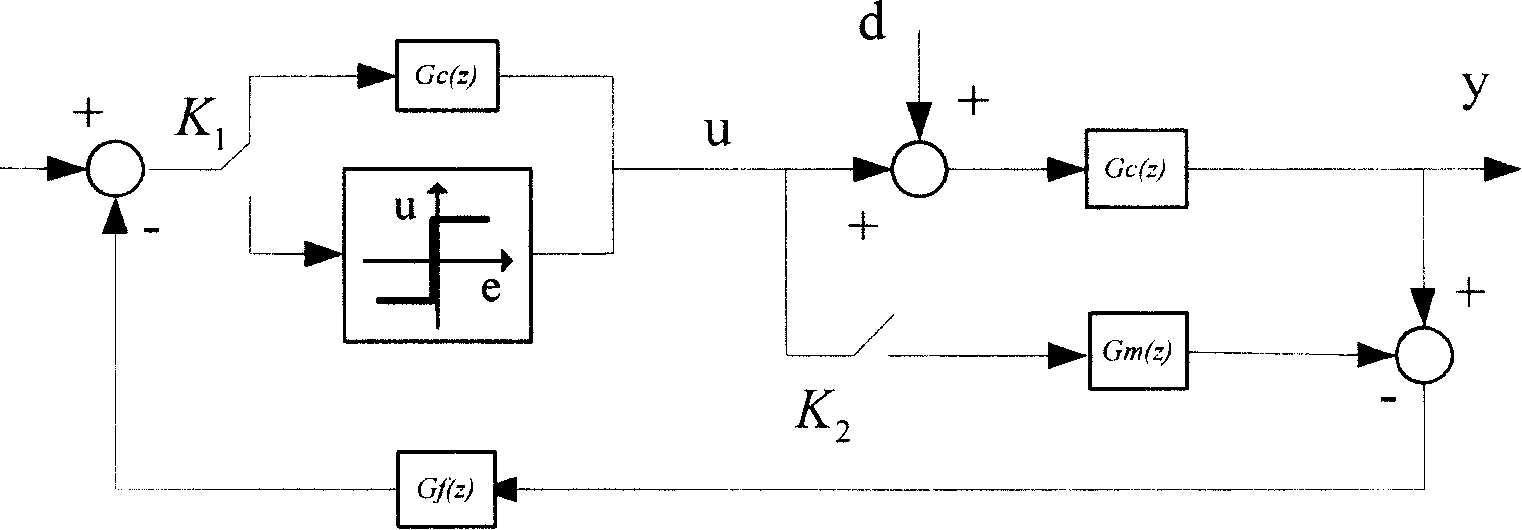

[0049] Such as figure 2 As shown, it represents the control block diagram of the present invention applied in the production process, and the control system operates according to the opening and closing of the two toggle keys.

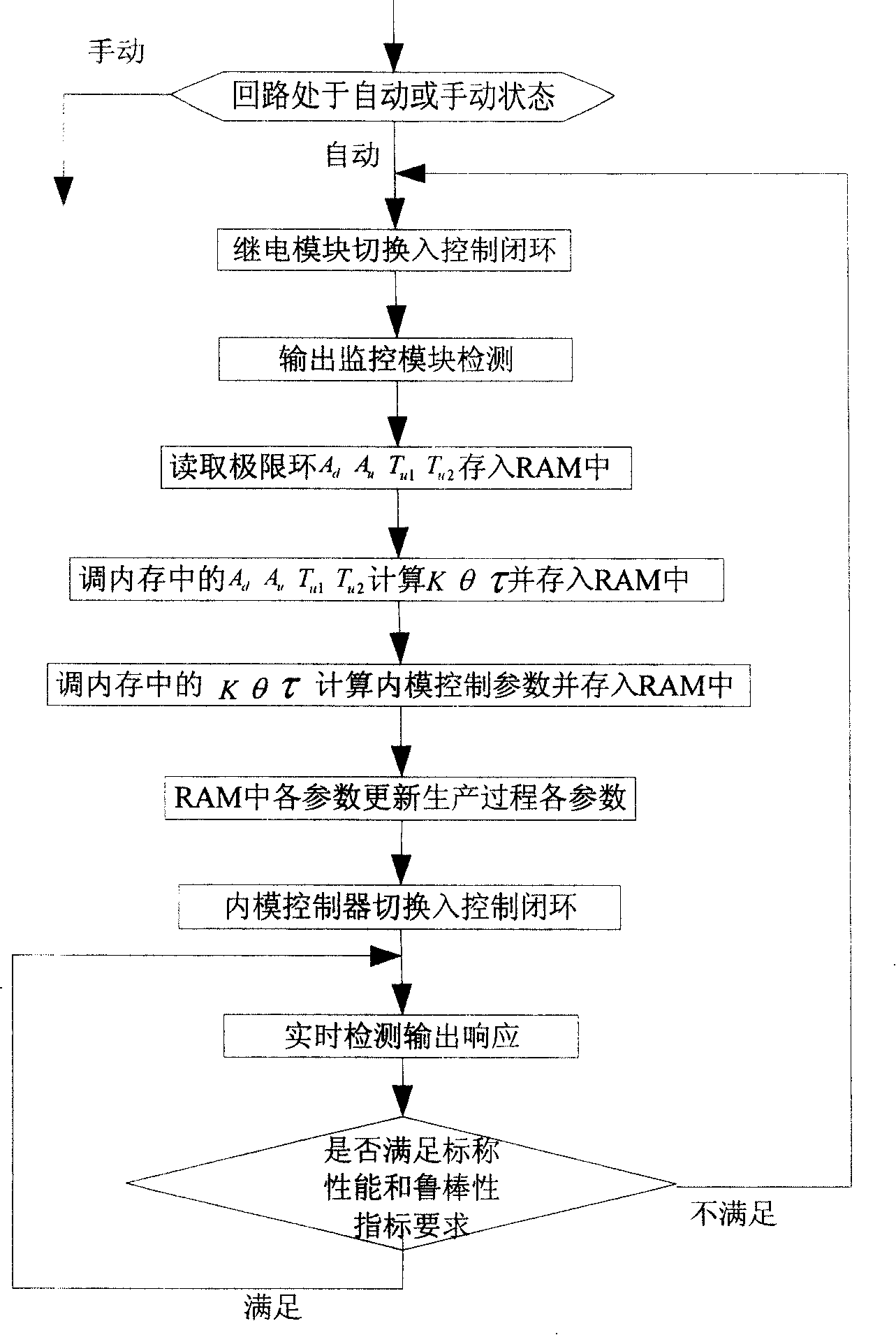

[0050] Such as image 3 Shown is the flow chart of the method of the present invention, and the whole system operates according to this flow.

[0051] As shown in Figure 4, the system is mainly composed of an operation console, a host computer, an output console and an output monitoring module. The operation control platform is the user interface, where engineers and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com