Intelligent lathe control method

A control method and lathe technology, applied in the field of lathe control, can solve the problems of difficult to give processing parameters, high cost, loss, etc., and achieve the effect of facilitating the adjustment of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0029] Intelligent lathe control method of the present invention mainly comprises the following steps:

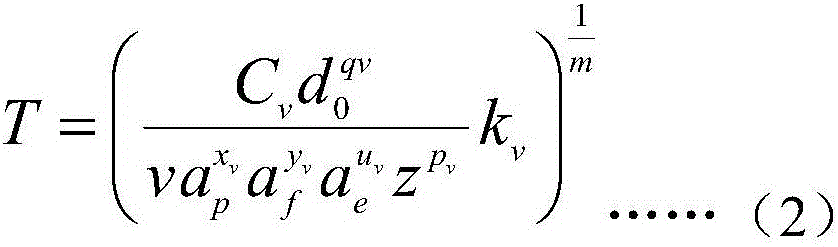

[0030] Step 1: In the process of processing, detect the current of the main motor and the deviation value returned by the grating scale in real time, there are 2 inputs and 1 output, that is, the structure of the BP neural network is determined to be 2-5-1, and the feed rate is a f The change of Δa f As a system adjustment amount, it realizes the closed-loop feedback learning control of the processing process;

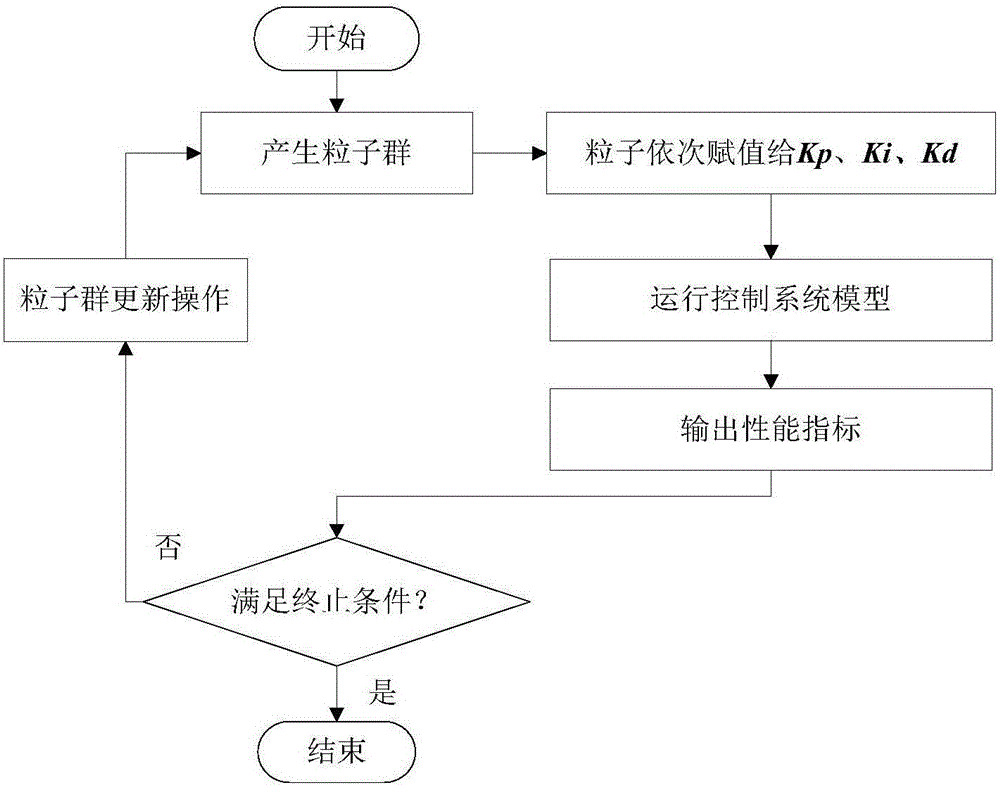

[0031] Step 2: In the process of processing the workpiece, the vibration of the machine tool workpiece (that is, the fluctuation of the grating ruler) is used as the input value, and the parameters of the servo drive are adjusted by using the particle swarm optimization algor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com