Rapid construction method adopting self-propelled inverted arch trestle

A construction method and self-propelled technology, which is applied to mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of increasing construction time and difficulty in ensuring the radian of the top surface of the inverted arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

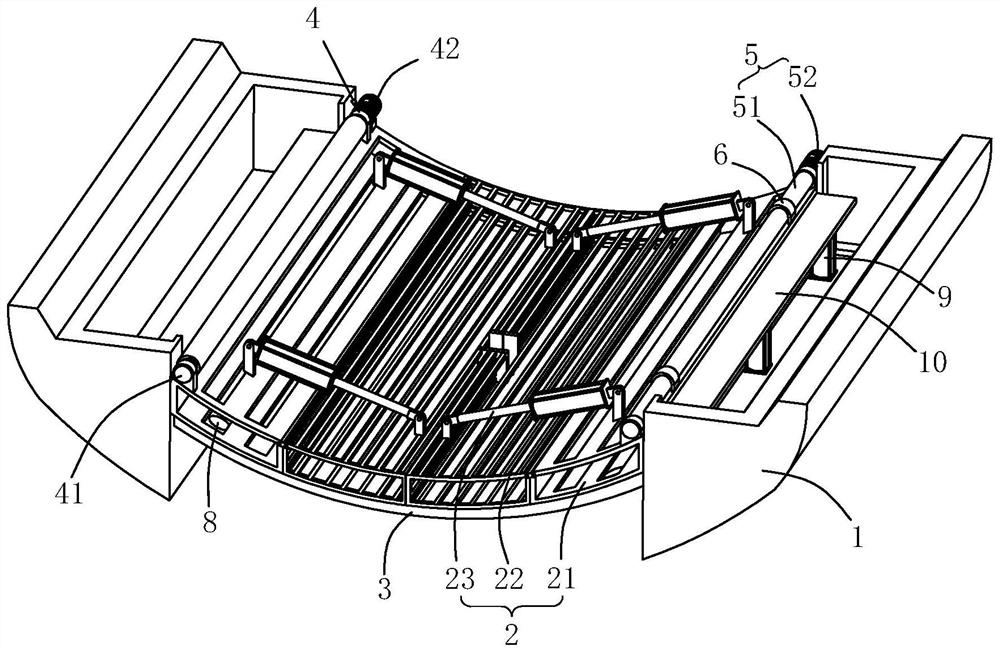

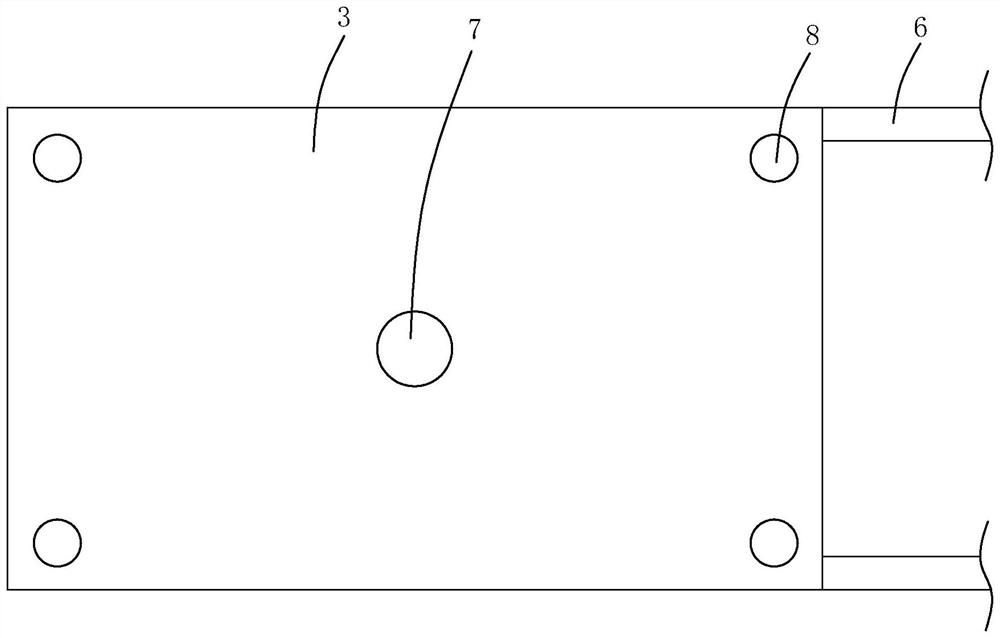

[0036] Attached to the following Figure 1-4 This application will be described in further detail.

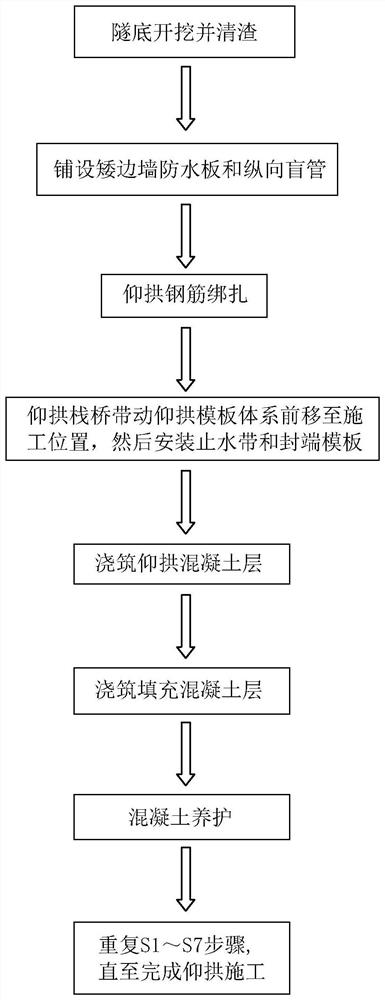

[0037] The embodiment of the present application discloses a rapid construction method using a self-propelled inverted arch trestle. refer to figure 1 , including the following steps:

[0038] S1. Use the excavator to cooperate with the dump truck to excavate the bottom of the tunnel and clear the slag. The construction of this process can be completed in the time of drilling the face of the face without affecting the construction of the face.

[0039] S2. Lay low side wall waterproofing boards and longitudinal blind pipes. Specifically: the longitudinal blind pipe is reverse-wrapped with geotextile and waterproof board according to the design and fixed on the primary support surface of the shotcrete at the lower part of the side wall, and the exposed lap joint of the waterproof board at the construction joint shall not be less than 1m. The waterproof board is welded with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com