Underground coal mine nearly horizontal directional drilling large-diameter steel sleeve hole completion system and method

A horizontal directional and directional drilling technology, applied in drilling equipment and methods, directional drilling, earthwork drilling, etc., can solve the problem that the uniformity of grouting thickness needs to be further improved, avoid penetration cracks, improve running Ability, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

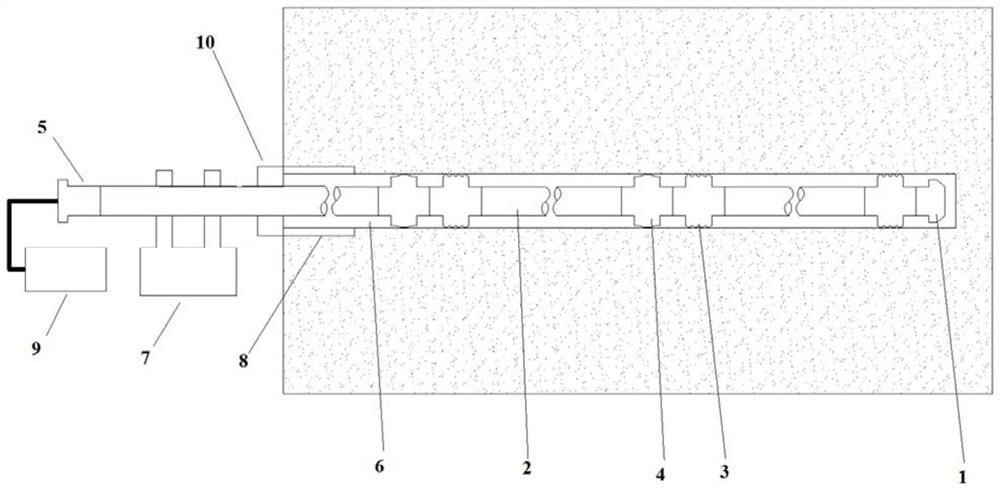

[0070] This embodiment provides a near-horizontal directional drilling large-diameter steel casing completion system in a coal mine, such as figure 1 As shown, it includes a casing guide head 1, a plurality of steel casing strings 2 and a slurry feeder 5 that are sealed and connected in sequence from front to back, a casing guide head 1 and a steel casing string 2 adjacent to the casing guide head 1 A drag-reducing supporter 3 is sealedly connected therebetween, and a drag-reducing supporter 3 and a pressure-limiting sealer 4 are sealed and connected in sequence from front to back between two adjacent steel casing strings 2 .

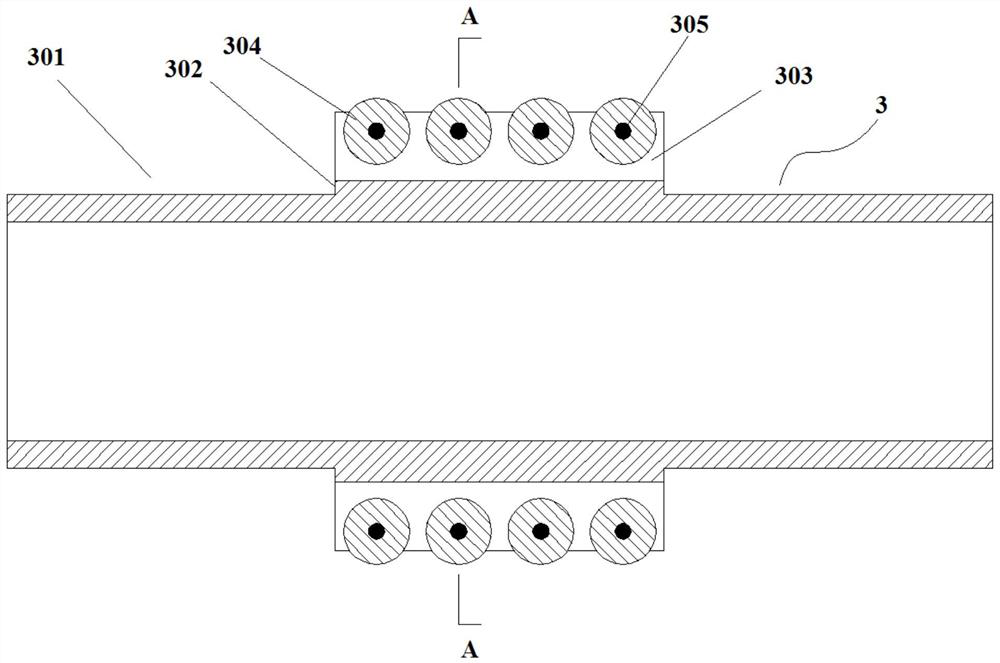

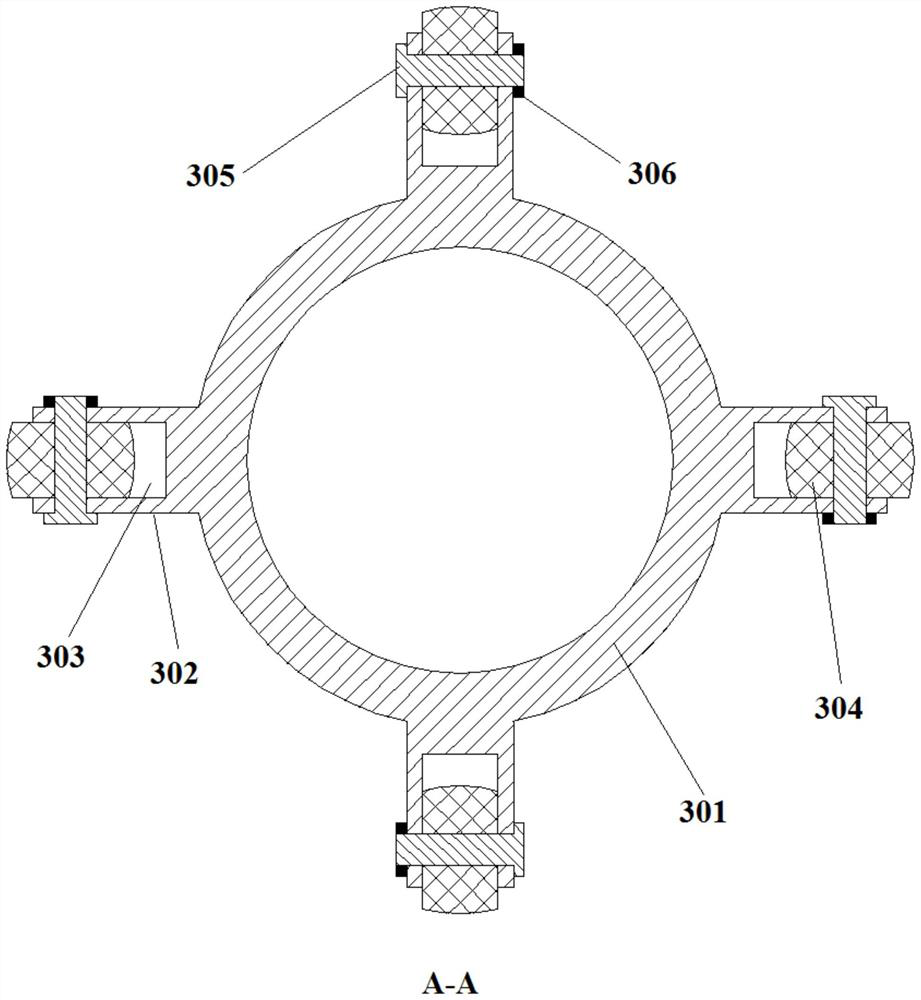

[0071] like figure 2 and image 3 As shown, the drag reducing supporter 3 includes a hollow supporting short section 301 , the middle of the outer wall of the supporting short section 301 is provided with a plurality of supporting ribs 302 along the circumferential direction, and the supporting ribs 302 are arranged along the axial direction. Roller ...

Embodiment 2

[0085] This embodiment provides a method for completing a large-diameter steel casing for near-horizontal directional drilling in a coal mine.

[0086] Specifically, the method includes the following steps:

[0087] Step 1, directional drilling construction:

[0088] First, use the directional drilling machine 7 to construct the directional drilling 6 orifice section, lower the orifice casing 8 and grouting to fix the pipe; then carry out directional drilling according to the design trajectory of the directional drilling 6, and exit the hole after reaching the design depth. to the drill.

[0089] Step 2, run the steel casing string:

[0090] Sealing and connecting the casing guide 1, multiple steel casing strings 2, drag reducing support 3, pressure limiting seal 4 and slurry feeder according to the connection relationship of the large-diameter steel casing completion system for near-horizontal directional drilling in coal mines 5. Use the directional drilling machine 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com