Preparation method of strippable ultrathin carrier copper foil

A technology of carrier copper foil and ultra-thin copper foil, which is used in the manufacture of printed circuits, the manufacture of printed circuit precursors, printed circuits, etc. Complete and other problems, to achieve the effect of low cost of technical transformation, enhanced bonding force, and satisfactory peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

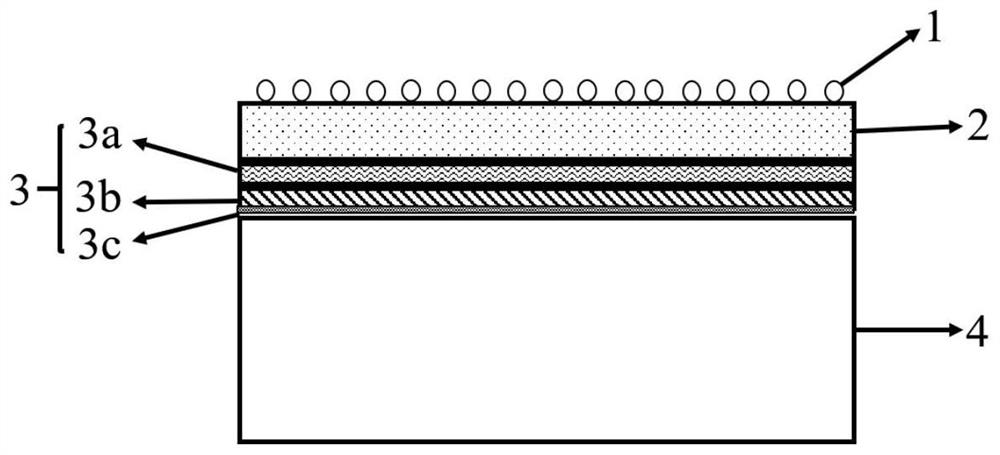

[0042] A preparation method of a peelable ultra-thin carrier copper foil, the copper foil sequentially comprises a carrier copper foil 4 with a thickness of 12-35 μm, a peeling layer 3, an ultra-thin copper foil layer 2 and a roughening layer 1 from bottom to top, and the composite peeling Layer 3 includes, from bottom to top, an immersion metal layer 3c, an organic barrier layer 3b, and a peeling layer 3a, and the preferred thickness of the ultra-thin copper foil is 4-6 μm.

[0043] Preparation includes the following steps:

[0044] (1) Preparation of cathode: Select double-sided copper foil for printed circuit board manufacturing as carrier copper foil, and perform micro-etching and pickling treatment on the smooth surface of carrier copper foil to obtain oxide-free and clean copper foil surface, All surface treatments are done on the smooth surface of the carrier copper foil;

[0045] (2) Preparation of immersion metal layer

[0046] The surface-treated carrier copper foi...

Embodiment 1

[0066] A preparation method of peelable ultra-thin carrier copper foil, comprising the following steps:

[0067] (1) Preparation of cathode: Cut a piece of 100mm×50mm wide 18μm double-sided copper foil for printed circuit board manufacturing with scissors, one of which is matte and the other is smooth. The surface treatments of all the following examples are on the smooth surface. The above-mentioned copper foil is subjected to micro-etching treatment and pickling treatment in turn to achieve the purpose of removing surface oxides and impurities, and then washed with deionized water to prepare for use.

[0068] (2) Preparation of immersion metal layer

[0069] Immersion metal layer on the surface of the carrier copper foil: Immerse the cleaned carrier copper foil in a mixed solution of 20g / L stannous chloride, 80g / L hydrochloric acid, and 50g / L sodium hypophosphite in sequence, and soak for 1min at 60°C After washing with deionized water, it was immersed in a hydrogen peroxid...

Embodiment 2

[0085] A preparation method of peelable ultra-thin carrier copper foil, comprising the following steps:

[0086] (1) Preparation of cathode: Cut a piece of 100mm×50mm wide 18μm double-sided copper foil for printed circuit board manufacturing with scissors, one of which is matte and the other is smooth. The surface treatments of all the following examples are on the smooth surface. The above-mentioned copper foil is subjected to micro-etching treatment and pickling treatment in turn to achieve the purpose of removing surface oxides and impurities, and then washed with deionized water to prepare for use.

[0087] (2) Preparation of immersion metal layer

[0088] Immersion metal layer on the surface of the carrier copper foil: Immerse the cleaned carrier copper foil in a mixed solution of 20g / L stannous chloride, 80g / L hydrochloric acid, and 50g / L sodium hypophosphite in sequence, and soak for 1min at 60°C After washing with deionized water, it was immersed in a hydrogen peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com