Device and method for preparing gas-based shaft furnace reducing gas by purifying biomass gas

A gas-based shaft furnace and biomass gas technology, applied in chemical instruments and methods, shaft furnaces, furnaces, etc., can solve the problems of high production cost, waste of heat, air pollution, etc., to improve active ingredients, avoid air pollution, The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

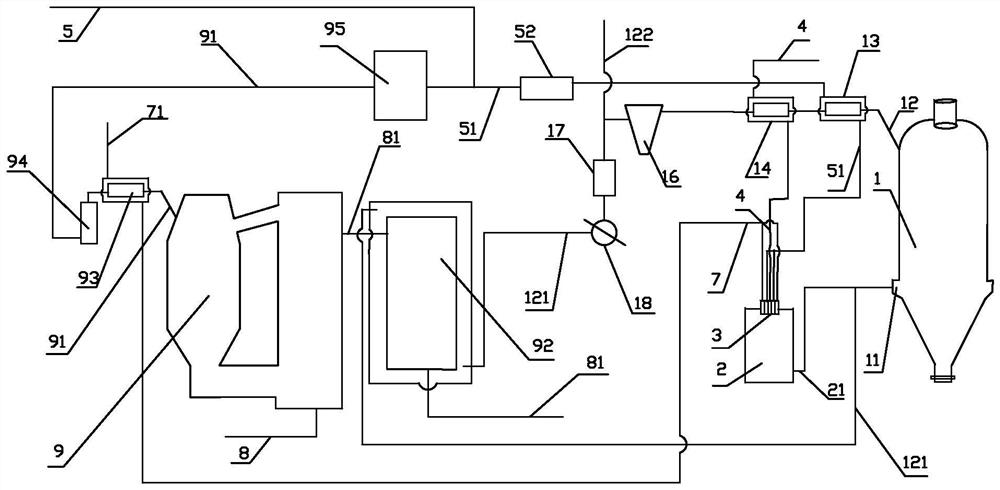

[0035] Embodiment 1: Combining figure 1 , figure 2 , Figure 4 to Figure 6 Illustrating this embodiment, this embodiment includes a gas-based shaft furnace 1, a gas-based shaft furnace top purification gas heating device, a biomass generator 9, a biomass gas ammonia water cooler 94, a biomass gas purification system 95, and a non-catalytic part Oxidation reformer 2, gas compressor 52, gas-based shaft furnace top hot gas heat exchanger 1 13, gas-based shaft furnace top gas dust collector 16, gas-based shaft furnace top gas de-CO 2 components, hydrocarbon-rich gas source 5, pure oxygen source 4 and water vapor source 7;

[0036] The biomass generator 9 is sequentially communicated with the biomass gas ammonia water cooler 94 and the biomass gas purification system 95 through the ascending pipeline, and the biomass gas 91 generated in the biomass generator 9 flows through the biomass gas ammonia water cooler 94 and the biomass gas. The biomass gas purification system 95, the ...

specific Embodiment approach 2

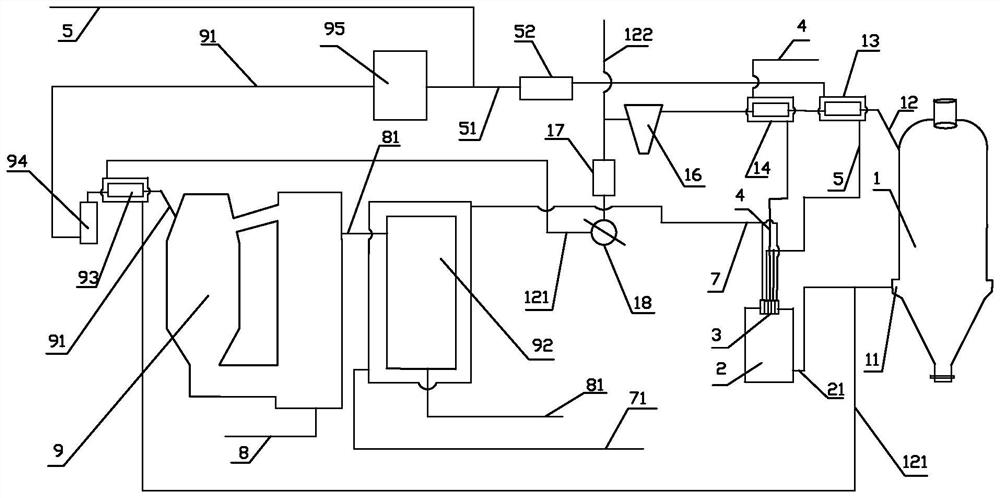

[0037] Specific implementation mode 2: Combining figure 1 , figure 2 , Figure 4 to Figure 6 Illustrating this embodiment, between the gas-based shaft furnace top hot gas heat exchanger 13 and the gas-based shaft furnace top gas dust collector 16 in this embodiment are also sequentially connected to the shaft furnace hot gas heat exchanger 2 14 and the shaft furnace. Hot gas heat exchanger three 15. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

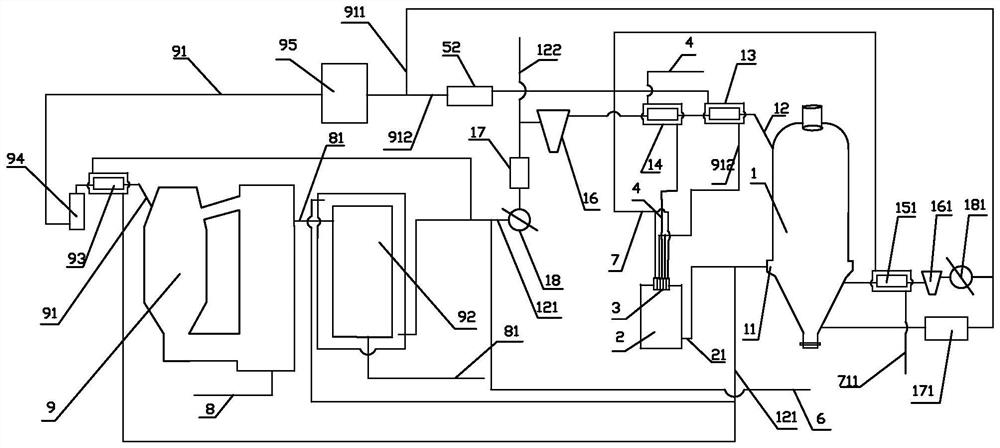

[0038] Specific implementation three: combination figure 1 , figure 2 , Figure 4 to Figure 6 Illustrating this embodiment, the gas-based shaft furnace top purification gas heating device in this embodiment is the biomass gas generator hot flue gas heat exchanger 92 and / or the biomass gas riser heat exchanger 93; the biomass generator 9 A biomass gas riser heat exchanger 93 is installed outside the riser pipe between the biomass gas ammonia water cooler 94, and a biomass generator hot flue gas heat exchanger 92 is installed outside the hot flue gas pipeline 81 of the biomass generator. . This arrangement facilitates selection of at least one heat exchange mode according to different operating conditions. Other compositions and connection relationships are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com