Processing technology of torreya grandis fruits

A processing technology, the technology of torreya fruit, which is applied in the direction of fat oil/fat production, fat production, fat oil/fat refining, etc., can solve the problems of oil and active ingredient damage, low quality of torreya oil, cumbersome processing steps, etc., and achieve improved separation Speed and effect, avoiding decomposition and oxidation, effect of simplifying treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

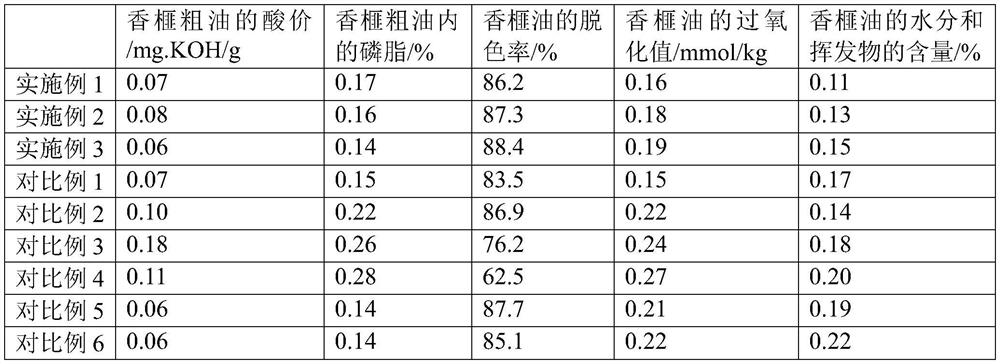

Examples

Embodiment 1

[0024] Rinse the picked fresh Torreya fruit and remove the aril to obtain Torreya fruit; rinse the aril residue on the surface of the Torreya fruit, dry it, fry it at 130°C for 15 minutes, and then press it several times at 60°C , to get the squeezed liquid.

[0025] The pressing liquid is heated to 75°C, and then a separating agent is added with stirring. The amount of the separating agent is 15 wt% of the pressing liquid, and the separating agent is 1 wt % of sodium carboxymethyl cellulose, 2 wt % of sodium chloride, and 0.2 wt of sodium bicarbonate. % aqueous solution; after mixing evenly, let stand for 3 hours, separate and remove the lower layer precipitate and solution, and obtain the upper layer of Torreya chinensis crude oil.

[0026] The crude oil of Torreya Torreya is heated to 70° C., and then a purifying agent is added to stir and mix evenly. The amount of the purifying agent is 3wt% of the crude Torreya Torreya oil. The purifying agent is sodium diacetate with a m...

Embodiment 2

[0028] Rinse the picked fresh Torreya fruit and remove the aril to obtain Torreya fruit; rinse the aril residue on the surface of the Torreya fruit, dry it, fry it at 140°C for 10 minutes, and then press it several times at 60°C , to get the squeezed liquid.

[0029] The pressing liquid is heated to 85°C, and then a separating agent is added with stirring. The amount of the separating agent is 20 wt% of the pressing liquid. The separating agent contains 1.5 wt % of sodium carboxymethyl cellulose, 3 wt % of sodium chloride, and 0.5 wt % of sodium bicarbonate. wt% aqueous solution; after mixing evenly, let stand for 2 hours, separate and remove the lower layer precipitate and solution, and obtain the upper layer of Torreya chinensis crude oil.

[0030] The crude oil of Torreya Torreya is heated to 80° C., and then a purifying agent is added to stir and mix evenly. The amount of the purifying agent is 4wt% of the crude Torreya Torreya oil. The purifying agent is sodium diacetate ...

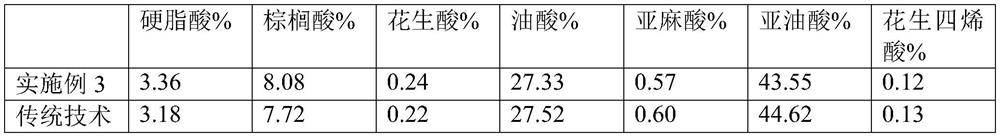

Embodiment 3

[0032] Rinse the picked fresh Torreya fruit and remove the aril to obtain Torreya fruit; rinse the aril residue on the surface of the Torreya fruit, dry it, fry it at 135°C for 12 minutes, and then press it several times at 60°C , to get the squeezed liquid.

[0033] The pressing liquid is heated to 80°C, and then a separating agent is added with stirring. The amount of the separating agent is 20 wt% of the pressing liquid, and the separating agent is 1.5 wt % of sodium carboxymethyl cellulose, 2.5 wt % of sodium chloride, and sodium bicarbonate. 0.5wt aqueous solution; after mixing evenly, let stand for 2 hours, separate and remove the lower layer precipitate and solution, and obtain the upper layer of Torreya chinensis crude oil.

[0034] The crude oil of Torreya Torreya is heated to 80° C., and then a purifying agent is added to stir and mix evenly. The amount of the purifying agent is 5wt% of the crude Torreya Torreya oil. The mixture of starch acetate is then cooled to 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com