Multi-cavity vacuum suction tool device

A vacuum suction, multi-chamber technology, applied in the field of suction tools, can solve problems such as poor segmentation control effect and inability to handle objects with special shapes and sizes, and achieve the effect of enhancing stability and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

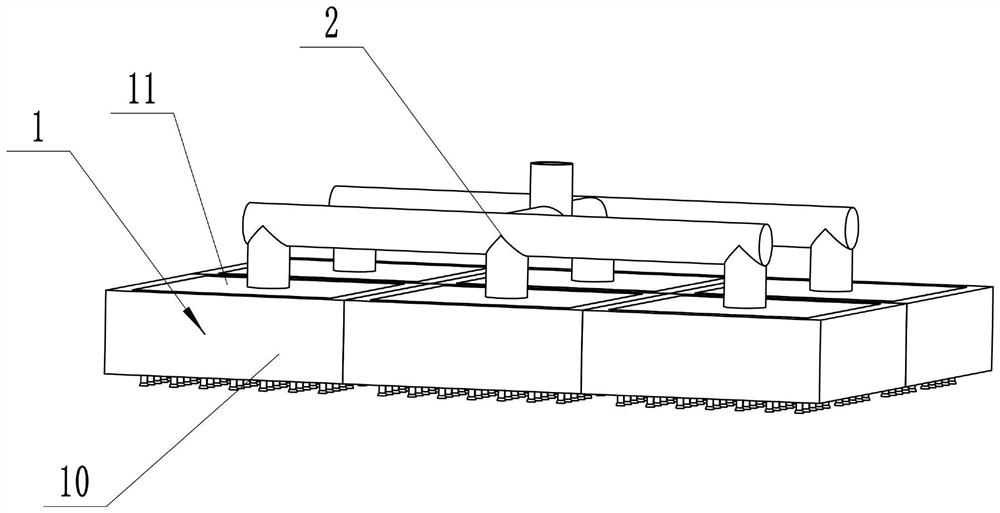

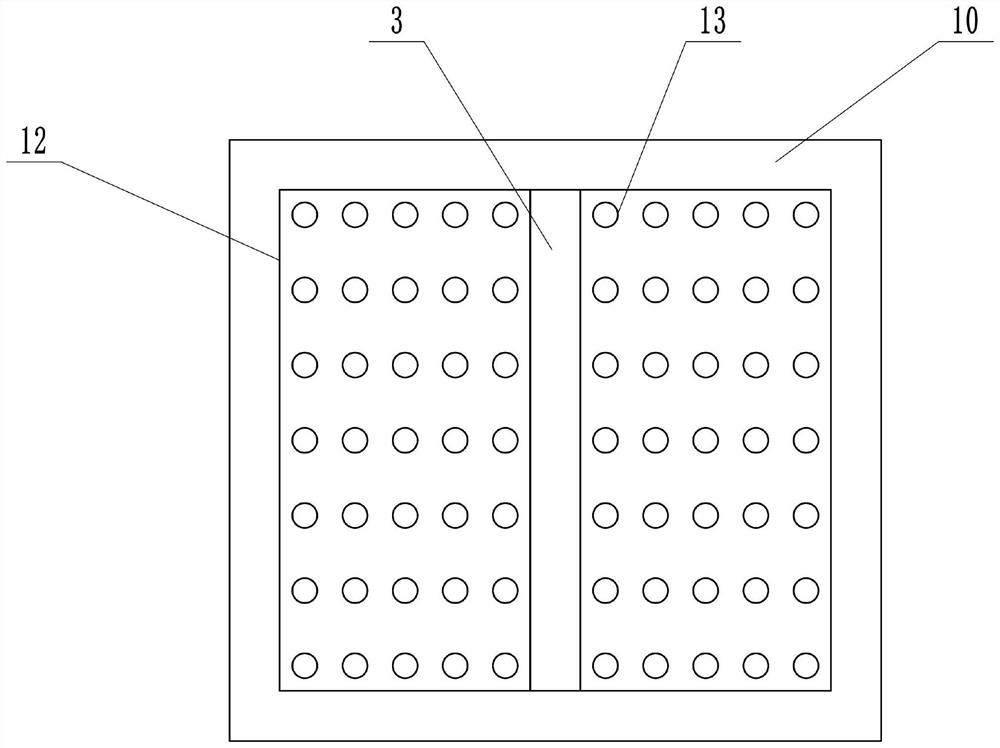

[0028] Example 1, as Figure 1-6 As shown, a multi-chamber vacuum suction device includes several vacuum chambers 1 . Several vacuum chambers 1 are spliced and combined. The vacuum chamber 1 is connected to a series pipe 2 which communicates all the vacuum chambers 1 . The vacuum chamber 1 includes a mounting shell 10 and a top cover 11 connected to the mounting shell 10 . The top cover 11 communicates with the series pipe 2 . The mounting shell 10 is provided with an inner cavity 12 . A mounting plate 3 is provided in the middle of the bottom surface of the inner cavity 12 . A retractable cover device 4 is arranged below the mounting plate 3 . The bottom surface of the inner cavity 12 is provided with a plurality of evenly arranged mounting holes 13 . The suction cup assembly 5 is elastically connected in the mounting hole 13 . A connecting hole 15 is provided on the inner side wall of the mounting hole 13 . One end of the connecting hole 15 communicates with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com