Multi-stage screening type tea winnowing machine with impurity removal function

A winnowing machine and screening technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of poor impurity removal effect, etc., to facilitate feeding, improve quality, Avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

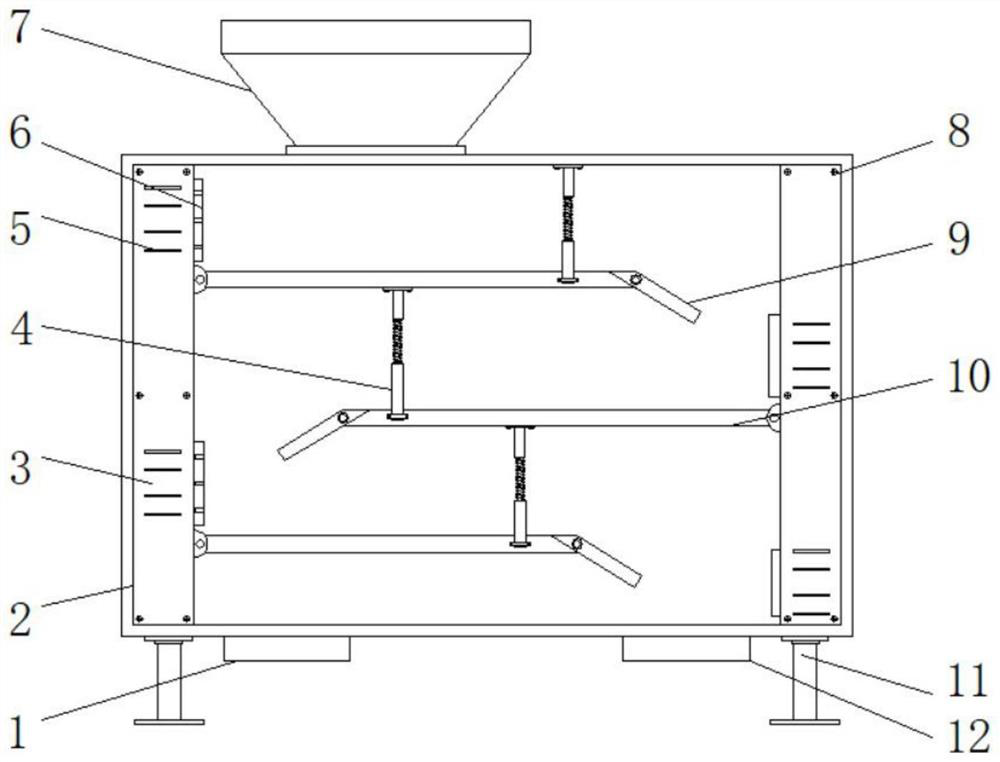

[0023] Example 1: see Figure 1-6 , a multi-stage screening type tea air sorter with impurity removal function, comprising a body 2, four corners of the bottom end of the body 2 are fixedly connected with legs 11, and one side of the bottom end of the body 2 is fixedly connected with an impurity outlet 1 , the other side of the bottom end of the body 2 is fixedly connected with a discharge port 12, the interior of the body 2 is hinged with three groups of screening plates 10, and four groups of screening fans 6 are installed on both sides of the inside of the body 2. The two ends of the screening plate 10 A connecting rod 4 is fixedly connected, two sides of one end of the body 2 are fixedly connected with a mounting plate 3, one side of the top of the body 2 is fixedly connected with a feeding port 7, and the top of the connecting rod 4 is fixedly connected with a telescopic rod 14. A connecting spring 15 is fixedly connected to the outside, and a guide plate 9 is hinged on o...

Embodiment 2

[0026] Example 2: A feeding roller 19 is movably connected to the inside of the feeding port 7, and the exterior of the feeding roller 19 is fixedly connected with multiple groups of feeding rods 17. A drive motor 16 is installed at one end of the port 7, and the output end of the drive motor 16 passes through the interior of the feed port 7 and is fixedly connected to one end of the feed roller 19;

[0027] Specifically, as figure 1 and Image 6 As shown, before the tea leaves enter the body 2 from the feeding port 7, the tea leaves are uniformly fed through the feeding roller 19, the driving motor 16 drives the feeding roller 19 to rotate at a constant speed, and the feeding rod 17 outside the feeding roller 19 can be The uniform amount of tea leaves are fed into the body 2 in turn, and the feeding roller 19 not only realizes the uniform feeding, but also avoids the blocking of the tea feeding material, and improves the stability of the air separator.

Embodiment 3

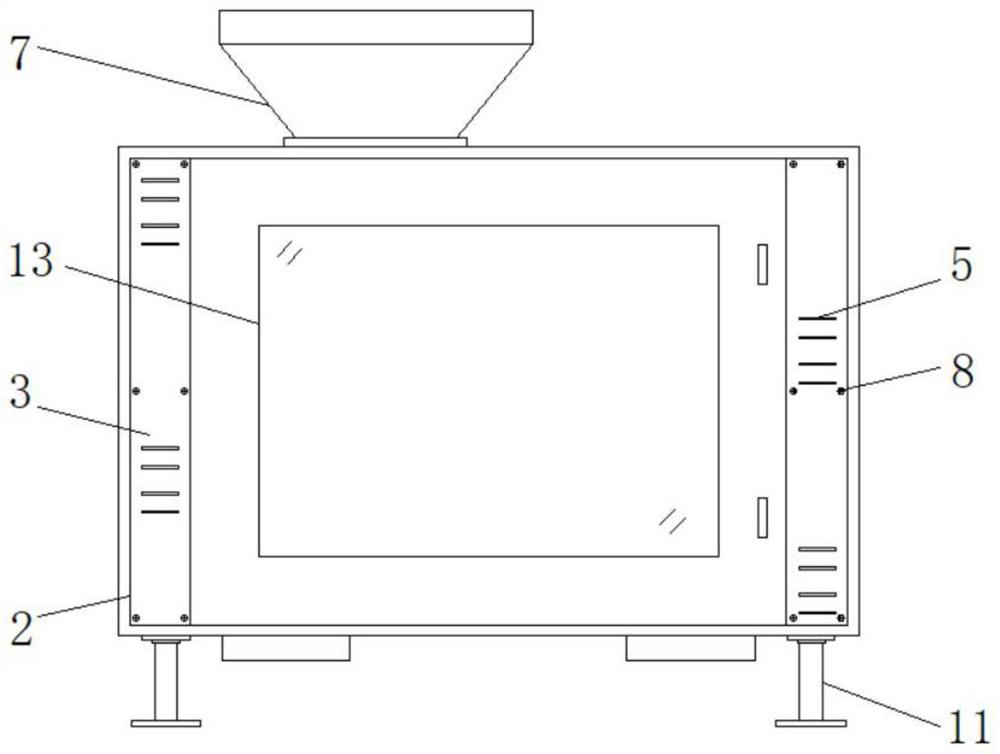

[0028] Embodiment 3: One end of the mounting plate 3 is installed with multiple groups of mounting bolts 8, one end of the mounting plate 3 is provided with multiple groups of air guides 5, and one end of the body 2 is fixedly connected with a viewing window 13;

[0029] Specifically, as figure 1 and figure 2 As shown, the air separator mainly uses the screening fan 6 to process the tea leaves. Once the screening fan 6 fails, it can be overhauled by removing the mounting plate 3. The mounting plate 3 is fixed by the mounting bolts 8, and the mounting bolts are removed during maintenance. 8. The mounting plate 3 can be removed. After removing the mounting plate 3, the internal screening fan 6 can be inspected and maintained. The inspection of the screening fan 6 does not contact the interior of the body 2, thereby improving the efficiency of inspection.

[0030] Working principle: when the present invention is in use, the tea leaves enter the first group of screening plates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com