Rapeseed cyclone flash dryer

A cyclone, dryer technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of low drying efficiency, unable to meet the needs of production, small drying amount, etc., to achieve sufficient heat exchange, guarantee Integrity, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

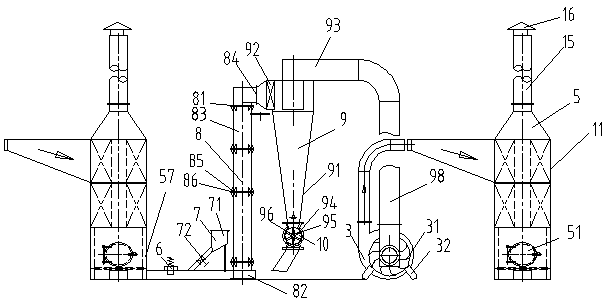

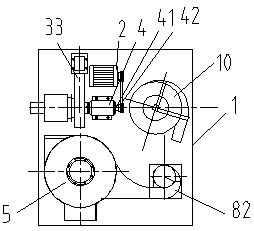

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

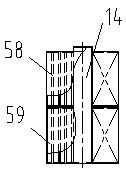

[0035] see Figure 1 to Figure 12 The cyclone flash dryer for rape in this embodiment includes a frame 1, a frequency conversion motor 2, a high-pressure centrifugal fan 3, a belt transmission group mechanism 4, a spiral plate type hot blast stove 5, a screw type K-type M6 metric thermocouple 6, a valve type Feeder 7, dryer 8, cyclone receiver 9, star unloader 10. The belt transmission group mechanism 4 includes a belt 42 and a shaft coupling 41. The casing of the shaft coupling 41 is semicircular and the rectangular plates at the extensions on both sides are screwed to the frame. The shaft of the motor 2 is connected, and the other side shaft is fixedly connected with the inner impeller 31 of the high-pressure centrifugal fan 3 . The high-pressure centrifugal fan 3 includes an impeller 31, a fan support 32, a fan casing 33, and a fan inlet pipe 98. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com