Lithium-rich manganese-based ternary composite precursor, positive electrode material and preparation method of positive electrode material

A lithium-rich manganese-based, ternary composite technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of Li+ not being able to fully re-embed, energy density drop, capacity loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

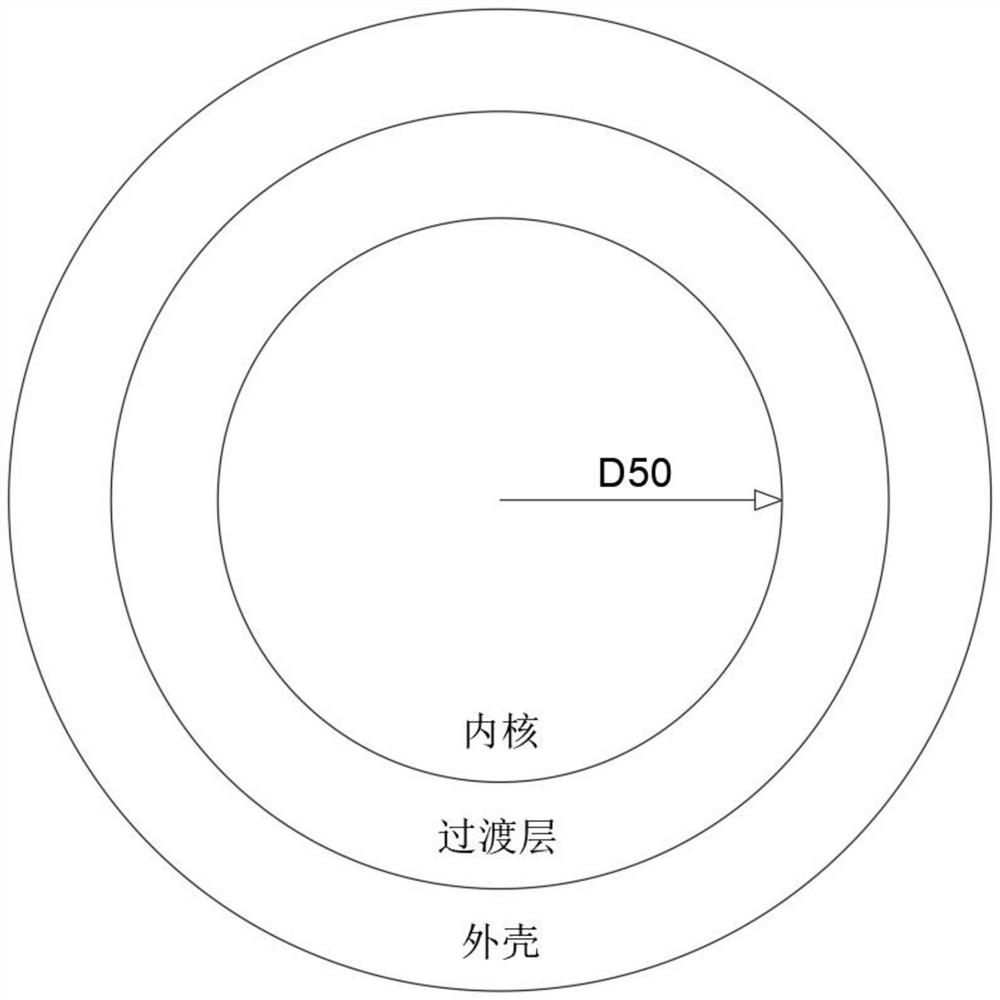

Image

Examples

Embodiment 1

[0058] Table 1 Electrical properties of lithium-rich manganese-based@ternary composite cathode materials with different compositions

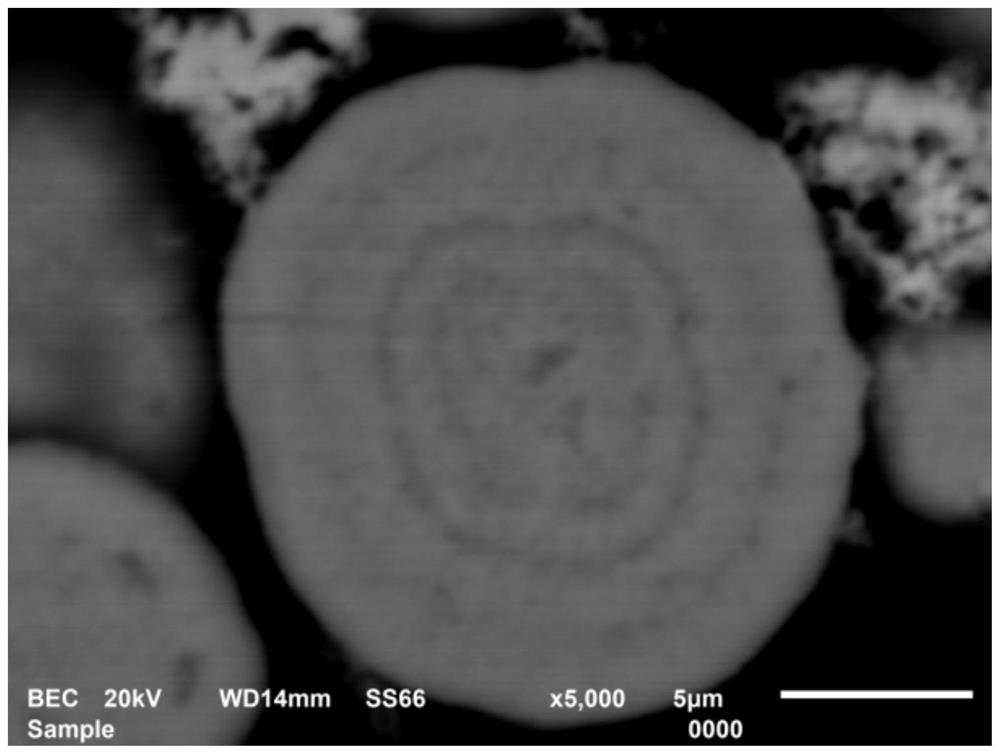

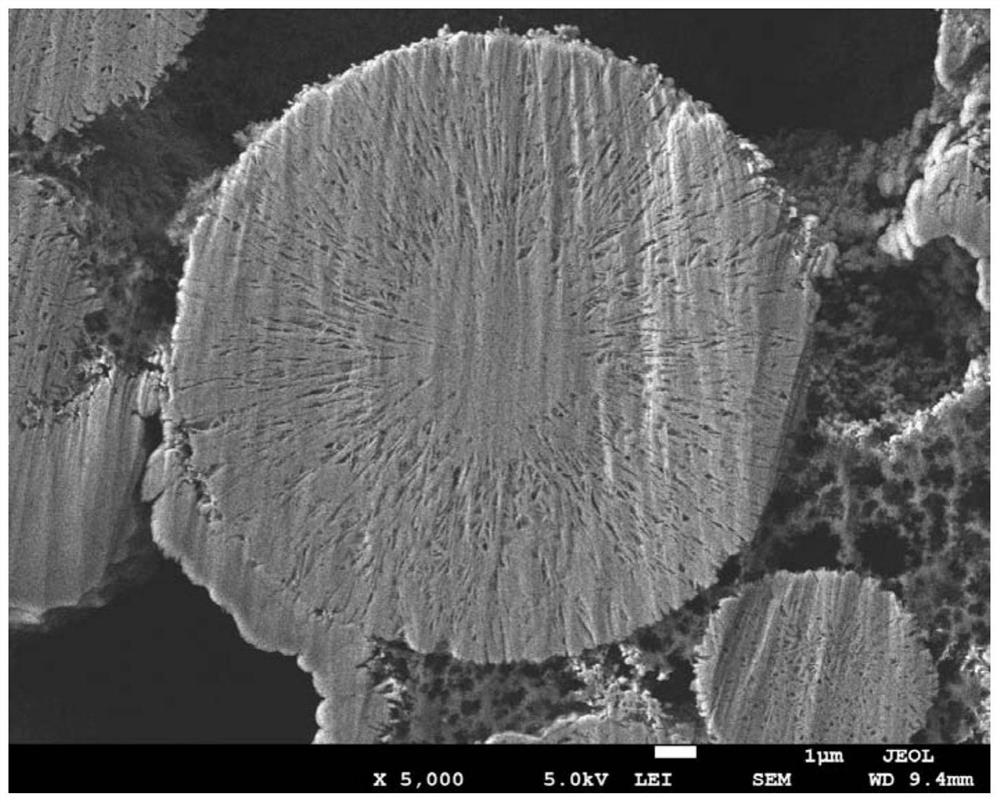

[0059] figure 2 and image 3 Shown are the cross-sectional electron microscopes of Comparative Example 1 and Comparative Example 2, both of which have a core-shell structure inside without an intermediate transition layer, and their electrical properties are worse than those of Example 1 as shown in Table 1.

[0060] The above-mentioned embodiments are only to illustrate the technical concept and characteristics of the present invention, and the purpose is to enable those skilled in the art to understand the content of the present invention and implement it accordingly, and not to limit the protection scope of the present invention. All equivalent changes or modifications made according to the spirit of the present invention shall fall within the protection scope of the present invention.

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com