Polyester film mechanical property detection device based on optical recognition

A technology of polyester film mechanics and optical recognition, which is applied in neural learning methods, image analysis, image enhancement, etc., can solve problems such as uneven force on local contact parts, detection features not found by the algorithm, and inability to respond in time, so as to avoid Sudden decrease in mechanical properties, improving detection accuracy, and avoiding the effects of background light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

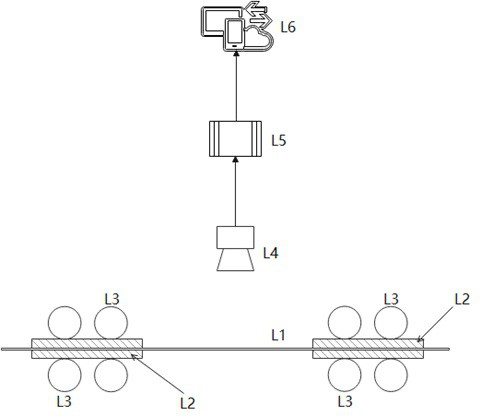

Image

Examples

Embodiment Construction

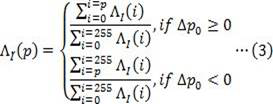

[0032] Since the brightness distribution of different images is easily affected by the environment, the average value of the measured material in the sample image and the collected image may be different; use formula (2) to calculate the offset of the measured material in the collected image relative to the sample image amount, and according to the offset Correct the brightness of the collected image to make the material-related pixel distribution in the collected image more uniform, and maintain the consistency of the material pixel distribution in multiple collected images, which is beneficial to the subsequent identification process:

[0033] Step 2: Detection of Cracks in Mylar Material Image

[0034] Input a preprocessed image:

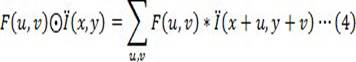

[0035] According to formula (4), select 16 groups of independent convolution kernels , ,..., . Correspondingly, 16 groups of mutually independent convolution responses can be generated:

[0036] Convolution Response Plot Contains a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com