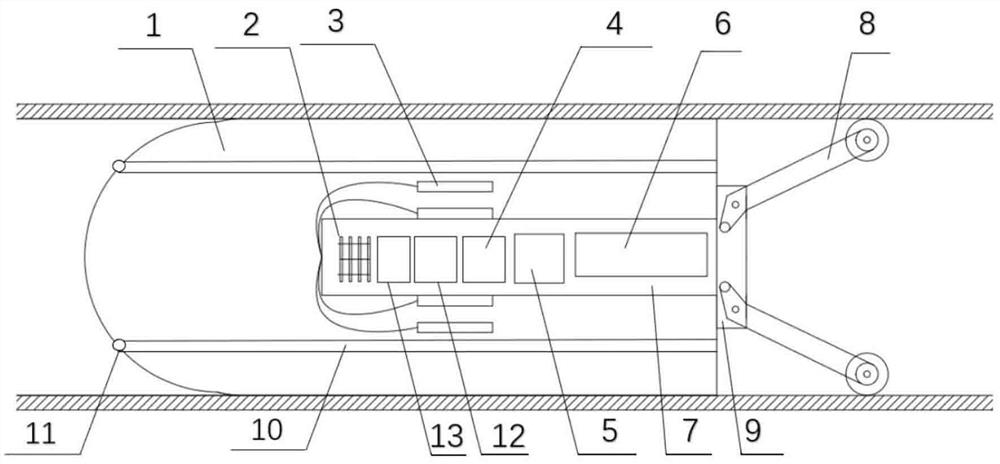

High-trafficability pipeline reducing detection and positioning device

A positioning device and pipeline technology, applied in measurement devices, navigation through speed/acceleration measurement, mechanical diameter measurement, etc., can solve the problems of intelligent control function and jamming without the inner wall of the pipeline, so as to reduce the risk of jamming and reduce the risk of jamming. The effect of stable signal and reduction of pigging times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

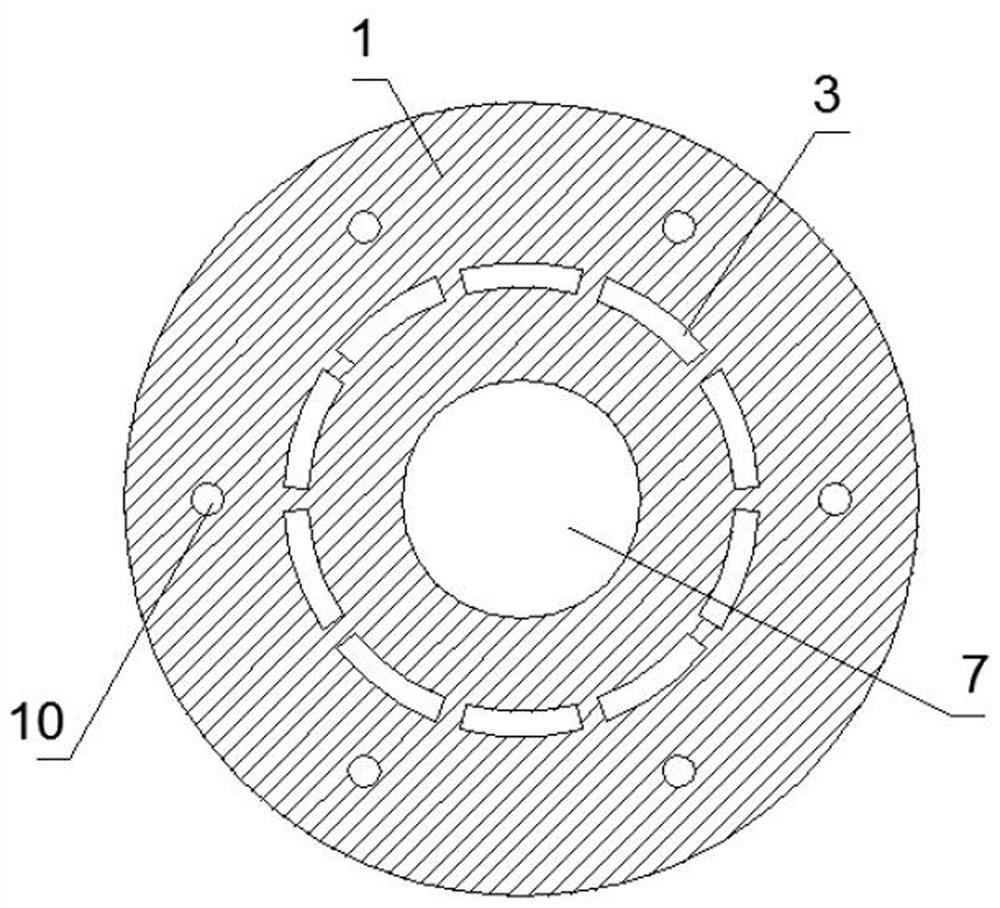

[0035] Polishing methods include: mechanical polishing, chemical polishing, electrolytic polishing, ultrasonic polishing, fluid polishing and magnetic abrasive polishing. Among them, mechanical polishing and chemical polishing are widely used.

[0036] Mechanical polishing, the mechanical polishing is to obtain a smooth surface by cutting and plastically deforming the surface of the material to remove the polished convex part. Generally, oil stone strips, wool wheels, sandpaper, etc. are used, mainly by manual operation, and special Auxiliary tools such as turntables can be used for the surface of parts such as rotary bodies, and ultra-fine grinding and polishing methods can be used for high surface quality requirements.

[0037] Chemical polishing, the chemical polishing is to make the microscopic convex part of the surface of the material dissolve preferentially compared with the concave part in the chemical medium, so as to obtain a smooth surface. The main advantage of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com