A shield type TBM segment backfill grouting expansion type sealing device and construction method

A technology of backfill grouting and sealing device, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of segment support force exerting influence on backfill quality, bean gravel stuck to shield, untimely backfill, etc. Guarantee the effect of backfill quality and segment support force, efficient construction and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

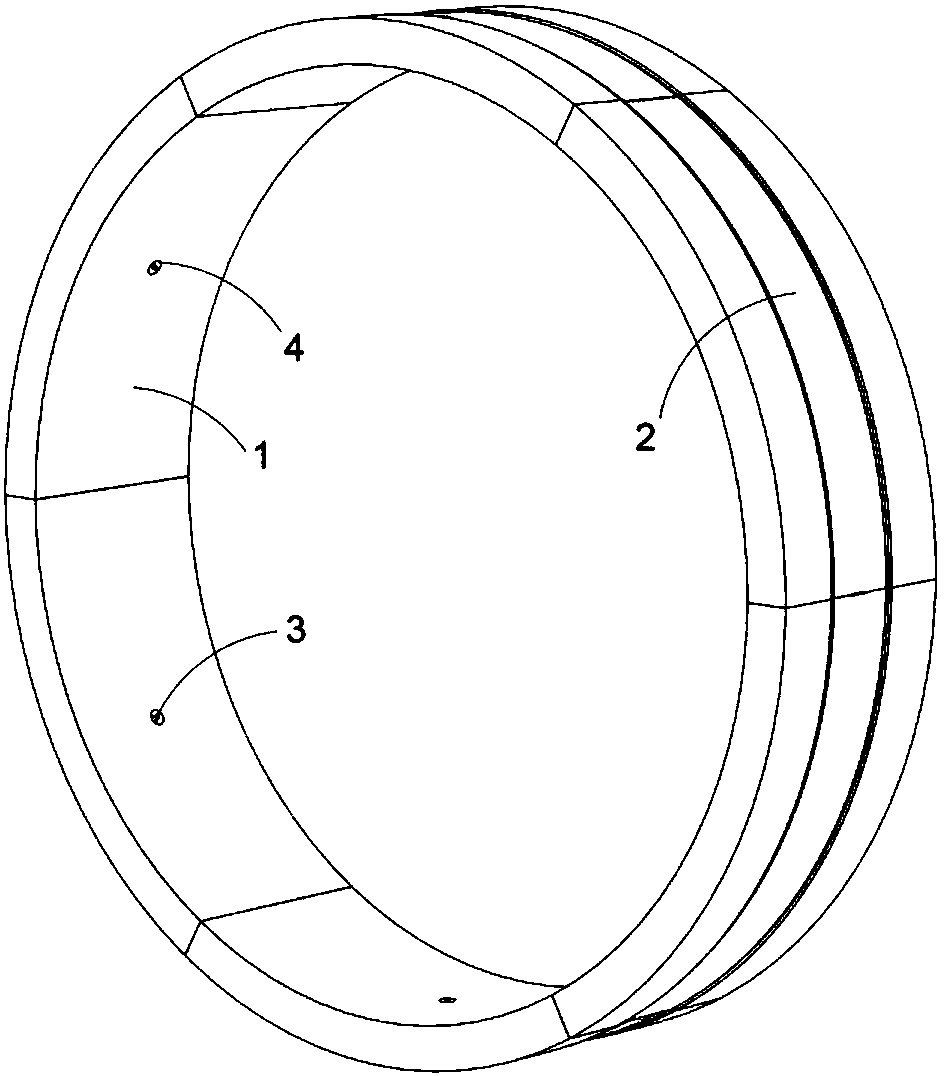

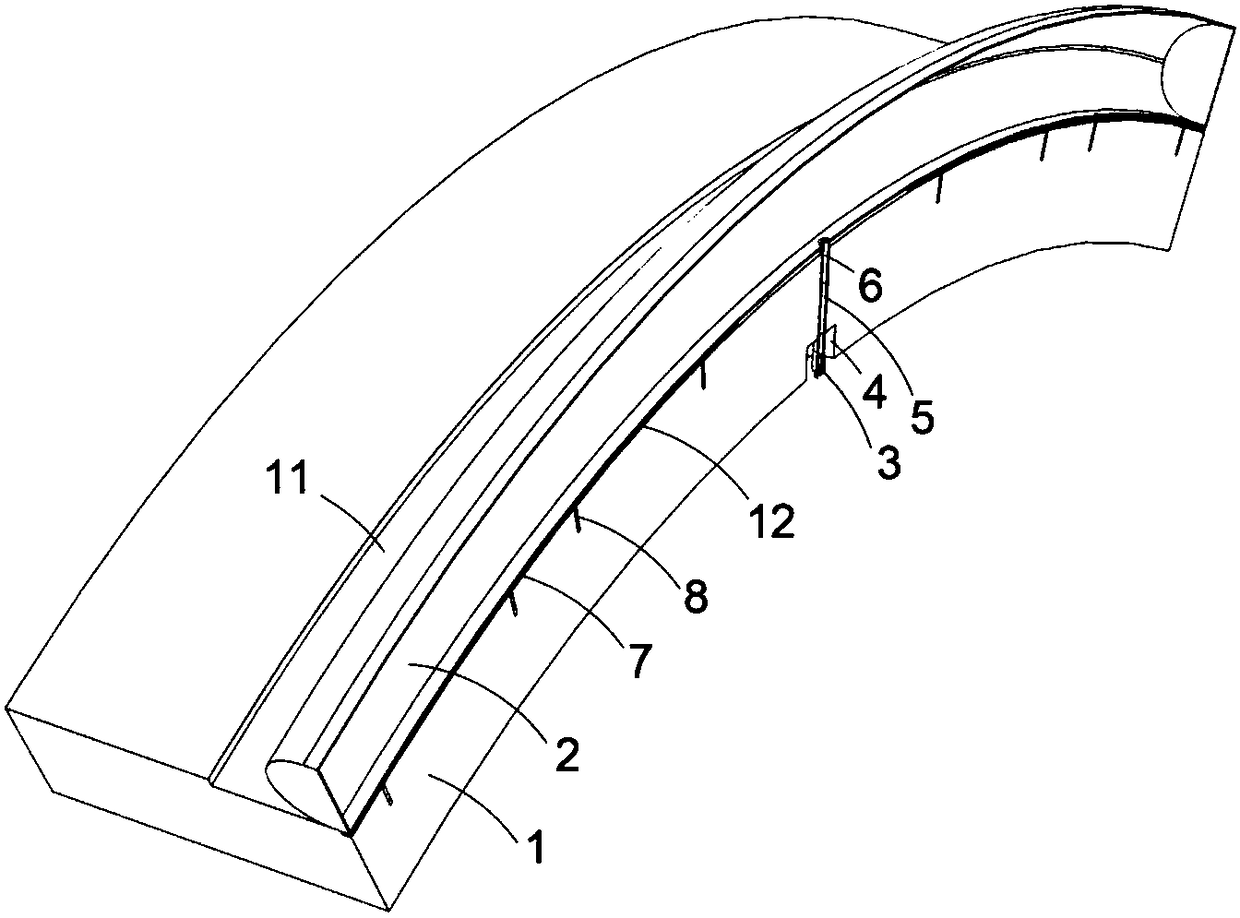

[0031] A shield-type TBM segment backfill grouting expansion type closure device, including segment 1, rubber bladder 2, air valve 3, segment valve hole 4, inflation tube extension tube 5, rubber bladder inflation tube 6, rubber bladder fixing strip 7. Anchor bolts for rubber bladder fixing strips 8, rubber bladder fixing sleeves 9, segment inflation tube holes 10, rubber bladder installation grooves 11, rubber bladder fixing strip installation grooves 12; rubber bladder installation grooves 11 are set on the outer peripheral surface of segment 1 Above, the installation groove 12 of the rubber bladder fixing strip is set in the rubber bladder installation groove 11, the rubber bladder fixing strip 7 is installed in the rubber bladder fixing strip installation groove 12 through the rubber bladder fixing strip anchor bolt 8, and the rubber bladder fixing sleeve 9 is located on the rubber bladder 2, the rubber bag 2 is fixed on the rubber bag fixing bar 7 through the rubber bag fi...

Embodiment 2

[0040]A shield-type TBM segment backfill grouting expansion type closure device, including segment 1, rubber bladder 2, air valve 3, segment valve hole 4, inflation tube extension tube 5, rubber bladder inflation tube 6, rubber bladder fixing strip 7. Anchor bolts for rubber bladder fixing strips 8, rubber bladder fixing sleeves 9, segment inflation tube holes 10, rubber bladder installation grooves 11, rubber bladder fixing strip installation grooves 12; rubber bladder installation grooves 11 are set on the outer peripheral surface of segment 1 Above, the installation groove 12 of the rubber bladder fixing strip is set in the rubber bladder installation groove 11, the rubber bladder fixing strip 7 is installed in the rubber bladder fixing strip installation groove 12 through the rubber bladder fixing strip anchor bolt 8, and the rubber bladder fixing sleeve 9 is located on the rubber bladder 2, the rubber bag 2 is fixed on the rubber bag fixing bar 7 through the rubber bag fix...

Embodiment 3

[0049] A shield-type TBM segment backfill grouting expansion type closure device, including segment 1, rubber bladder 2, air valve 3, segment valve hole 4, inflation tube extension tube 5, rubber bladder inflation tube 6, rubber bladder fixing strip 7. Anchor bolts for rubber bladder fixing strips 8, rubber bladder fixing sleeves 9, segment inflation tube holes 10, rubber bladder installation grooves 11, rubber bladder fixing strip installation grooves 12; rubber bladder installation grooves 11 are set on the outer peripheral surface of segment 1 Above, the installation groove 12 of the rubber bladder fixing strip is set in the rubber bladder installation groove 11, the rubber bladder fixing strip 7 is installed in the rubber bladder fixing strip installation groove 12 through the rubber bladder fixing strip anchor bolt 8, and the rubber bladder fixing sleeve 9 is located on the rubber bladder 2, the rubber bag 2 is fixed on the rubber bag fixing bar 7 through the rubber bag fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com