Material suction cup machining method of curved surface photoetching machine

A processing method and technology of lithography machine, applied in the field of mechanical processing, can solve the problems of difficulty in guaranteeing the quality of parts, high defect rate of product quality, affecting the qualified rate of products, etc. The effect of improving processing quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

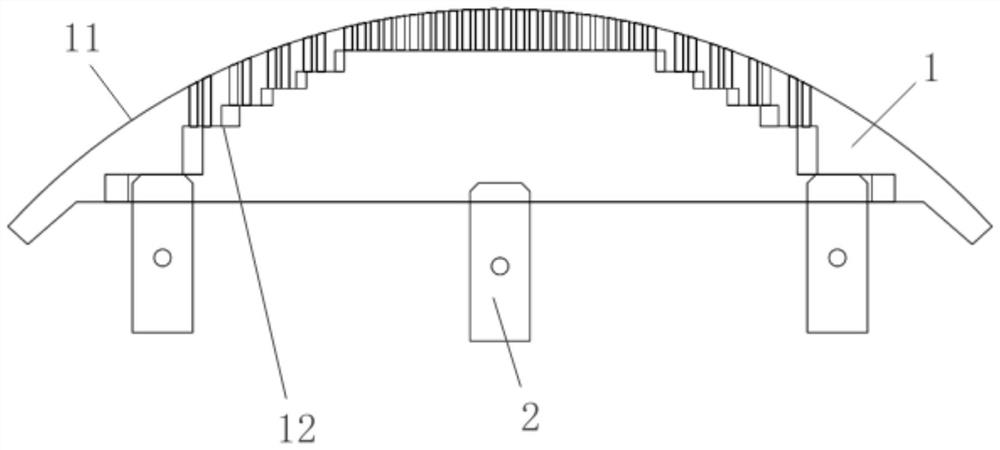

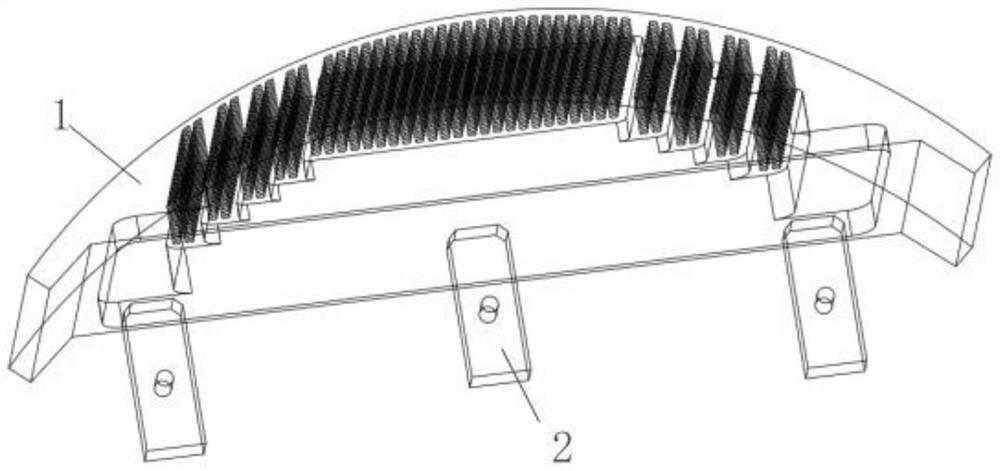

[0031] see Figure 1-4 , a material suction cup processing method of a curved lithography machine, comprising a base part 1, the base part 1 comprising a circular arc surface 11 and a cavity surface 12, including the following processing steps:

[0032] S1. Process the six vertical surfaces of the cavity surface 12 from the billet aluminum block of the base piece 1, mill the upper and lower planes to make allowances, and use the pressure plate 2 to fix the base piece 1 on the worktable of the machining center (refer to figure 1 ), the arc surface 11 is pre-processed, and a unilateral allowance is reserved;

[0033] Among them, the reserved allowance for milling the vertical plane on the six sides is 0.4~0.6mm, and the unilateral allowance for the initial processing arc surface 11 is 0.9~1.1mm, so as to prevent the deformation in the later stage and ensure the overall processing accuracy;

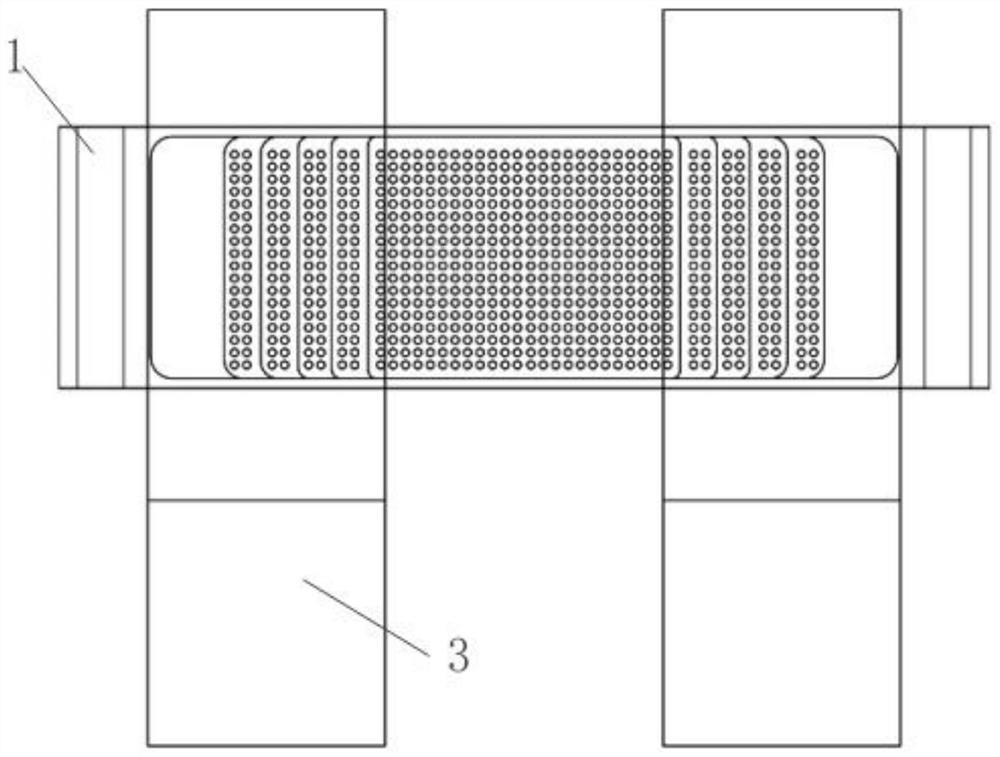

[0034] S2. Clamp the base piece 1 with the flat-nose pliers 3 (refer to figure 2 ), f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com