A kind of fluorine-free melting flux and its preparation method and application

A technology for melting flux and welding wire, which is applied in the field of fluorine-free melting flux and its preparation, and achieves the effects of low operator requirements, excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The fluorine-free smelting flux provided in this embodiment is made of the following components by mass percentage: SiO 2 24%, MnO 36% and TiO 2 40%.

[0062] The preparation method of the fluorine-free smelting flux provided by this embodiment includes the following steps:

[0063] (1) Weigh SiO according to the above ratio 2 , MnO and TiO 2 , mix it evenly, put it in a graphite crucible, smelt at 1500 ° C, and keep the temperature for 25 minutes to obtain a smelting material; perform water quenching on the smelting material to obtain a water-quenched material;

[0064] (2) placing the water-quenched material obtained in step (1) in a muffle furnace, and calcining at 700° C. for 2 hours to obtain a calcined material;

[0065] (3) Crushing and sieving the calcined material obtained in step (2) in turn to obtain a fluorine-free smelting flux with a particle size of 10 meshes to 120 meshes.

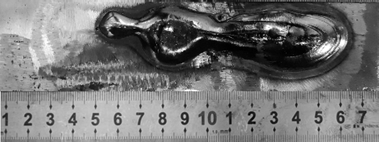

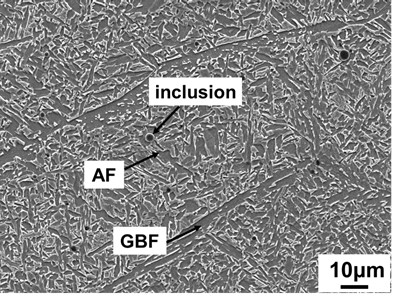

[0066] Then, the fluorine-free smelting flux prepared in the above steps w...

Embodiment 2

[0068] The fluorine-free smelting flux provided in this embodiment is made of the following components by mass percentage: SiO 2 28%, MnO 42% and TiO 2 30%.

[0069] The preparation method of the fluorine-free smelting flux provided in this embodiment is basically the same as that in Embodiment 1, except that: first, in step (1), the smelting temperature is 1450°C, and the smelting holding time is 30 minutes; second, the step In (2), the calcination temperature is 750°C and the time is 1h.

[0070] Then, the dried fluorine-free smelting flux prepared in the above steps is used for welding, and the welding parameters are exactly the same as those in Example 1.

Embodiment 3

[0072] The fluorine-free smelting flux provided in this embodiment is made of the following components by mass percentage: SiO 2 32%, MnO 48% and TiO 2 20%.

[0073] The preparation method of the fluorine-free smelting flux provided in this example is exactly the same as that in Example 2.

[0074] Then, the dried fluorine-free smelting flux prepared in the above steps is used for welding, and the welding parameters are exactly the same as those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com