A kind of production device and method for manufacturing electronic grade hydrogen chloride

A production device and hydrogen chloride technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of small production capacity, high energy consumption, and failure to meet market demand, so as to reduce impact and achieve high economy Effects of Benefits and Environmental Benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

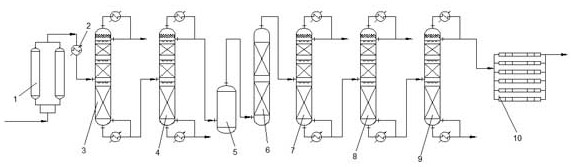

[0026] like figure 1 As shown, the embodiment of the present invention discloses a production device for producing electronic grade hydrogen chloride, including an adsorption tower 1, a cooler 2, a raw material rectification tower 3, a first weight removal tower 4, a flash tank 5, a reactor 6, Light-removing tower 7, motor tower 8, second weight-removing tower 9 and membrane separation device 10, the tower top outlet of adsorption tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com