A self-cleaning solar power supply system for household microgrid and preparation method of solar cell thereof

A technology for solar cells and power supply systems, applied in battery circuit devices, circuits, current collectors, etc., can solve problems such as affecting photoelectric conversion efficiency, attaching large dust or debris, and being unusable, achieving full and efficient utilization and simple components , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

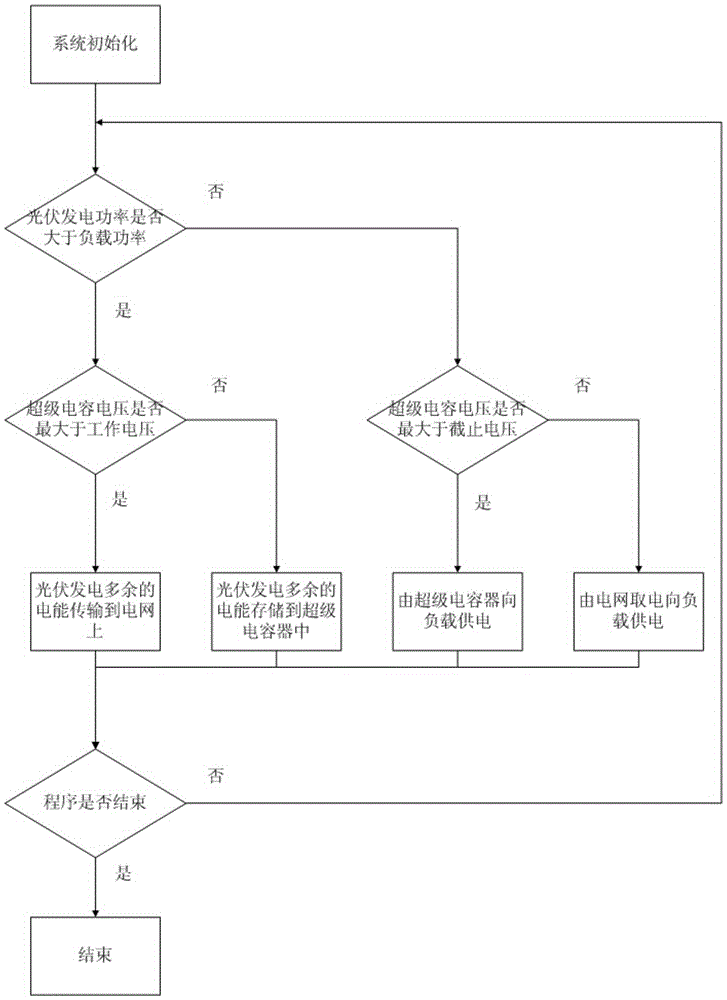

[0026] The self-cleaning solar energy power supply system of a kind of household microgrid of the present invention, as figure 1 As shown, it includes microgrid and control system; microgrid includes solar panels prepared with nano-diamond films on the surface, inverters and supercapacitors connected to the output of solar panels, and electrical loads connected to the output of inverters; super The output end of the capacitor is connected to the input end of the inverter, and the input end of the electrical load and the output end of the inverter are also respectively connected to the conventional power grid; the control system includes a single-chip microcomputer for selecting the type of electrical load connected to the power supply, which are respectively set in The electrical load and the power collector on the solar panel, the monitoring terminal and the data transceiver module set at the output end of the single-chip microcomputer; the input end of the single-chip microco...

example 2

[0032] A self-cleaning solar energy power supply system of a household micro-grid of the present invention is the same as Example 1.

[0033] The present invention is a method for preparing a solar cell used in the self-cleaning solar power supply system of the household microgrid described above, mixing nano-diamond powder with ethyl cellulose and a solvent according to a mass ratio of 1:3:15 to form a slurry , prepare a nano-diamond film on the solar cell packaging glass by the glue-spinning method, and fix it by sintering.

[0034] Wherein, during mixing, the nano-diamond powder and ethyl cellulose are ultrasonically heated and dispersed in a solvent to obtain a slurry after 2 hours, and the solvent is terpineol. When preparing nano-diamond films on solar cell packaging glass by the glue-spinning method, first fix the glass substrate on the glue-spinning machine, use a glass rod to drop the slurry on the glass, start the sol-gel glue-spinning machine to shake the glue, and ...

example 3

[0036] A self-cleaning solar energy power supply system of a household micro-grid of the present invention is the same as Example 1.

[0037] The present invention is a method for preparing a solar cell used in the self-cleaning solar power supply system of the household microgrid described above, mixing nano-diamond powder with ethyl cellulose and a solvent according to a mass ratio of 1:3:20 to form a slurry , prepare a nano-diamond film on the solar cell packaging glass by the glue-spinning method, and fix it by sintering.

[0038] Wherein, during mixing, the nano-diamond powder and ethyl cellulose are ultrasonically heated and dispersed in a solvent for 2.5 hours to obtain a slurry, and the solvent is terpineol. When preparing nano-diamond films on solar cell packaging glass by the glue-spinning method, first fix the glass substrate on the glue-spinning machine, use a glass rod to drop the slurry on the glass, start the sol-gel glue-spinning machine to shake the glue, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com