Extreme-high-temperature thermal intensity experiment system of complex curved surface structure for aerospace plane test

A technology for aerospace aircraft and complex curved surfaces, which is applied in the field of extreme high-temperature thermal strength experiment systems for complex curved surface structures used in aerospace aircraft testing. The effect of fast change speed and high temperature peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

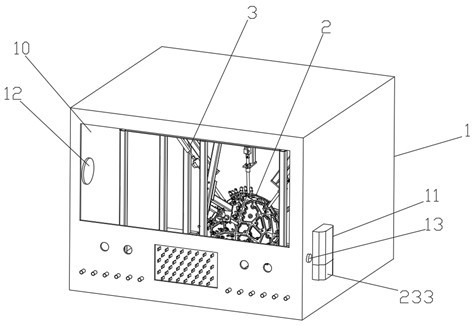

[0044] like figure 1 The shown experimental system for extreme high temperature thermal strength of complex curved structures for aerospace aircraft testing includes a micro-oxygen environment control system 1, which is set in the micro-oxygen environment control system 1 for heating the multi-temperature area extreme high temperature heating of the curved surface parts of the aircraft. Device 2, a loading device 3 arranged in the micro-oxygen environment control system 1 for applying a load to the aircraft curved surface part;

[0045] The micro-oxygen environment control system 1 includes a gas-tight cabin 10, a protective gas input device 11 communicated with the gas-tight cabin 10, an oxygen content monitoring system 12 disposed in the gas-tight cabin 10, and an oxygen content monitoring system 12 disposed in the gas-tight cabin 10. The gas pressure relief valve 13 on the gas-tight cabin 10;

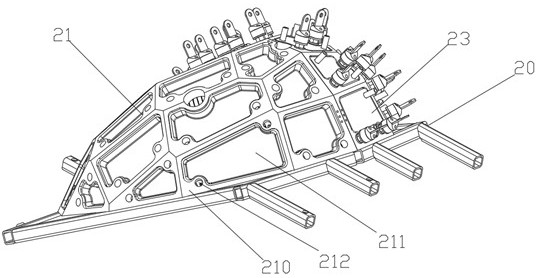

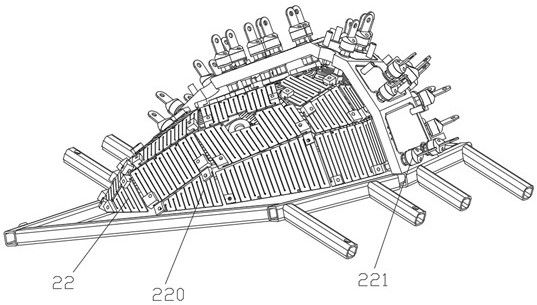

[0046] like figure 2 As shown, the multi-temperature zone extreme high temper...

Embodiment 2

[0065] The difference from Example 1 is that:

[0066] The length of the inner space of the radiation heating device 22 is 5m, the width is 4m, and the height is 5m.

[0067] The thickness of the graphite heating plate is 8 mm; the gap between adjacent graphite heating plates is 6 mm.

[0068] like Figure 7 As shown, the high temperature and high current composite electrode 221 includes an insulating sleeve 222 arranged in the mounting hole 212, a conductive column 223 arranged in the insulating sleeve 222 and connected to the heating plate 220 at one end, arranged in the insulating sleeve 222. The copper terminal 224 at the other end of the conductive column 223;

[0069] Both ends of the conductive post 223 are connected with boss threads 225;

[0070] The conductive posts 223 are respectively connected to the red copper terminals 224 and the heating plate 220 through the boss threads 225;

[0071] A water cooling circuit 226 is arranged in the red copper terminal 224 ....

Embodiment 3

[0074] The difference from Example 1 is:

[0075] The length of the inner space of the radiation heating device 22 is 3.5 m, the width is 3 m, and the height is 3 m.

[0076] The modular heating unit 210 is a metal copper plate;

[0077] The thickness of the graphite heating plate is 5 mm; the gap between adjacent graphite heating plates is 4 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com