Process and equipment for processing helical tooth-shaped trimming triangular belt

A technology of V-belt and tooth shape, applied in the direction of belts, other household appliances, household appliances, etc., can solve the problems of fatigue resistance, poor flexibility resistance, affecting the service life of the V-belt, limited use of the calender, etc. Good elongation resistance, good heat dissipation effect, and the effect of reducing lateral deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

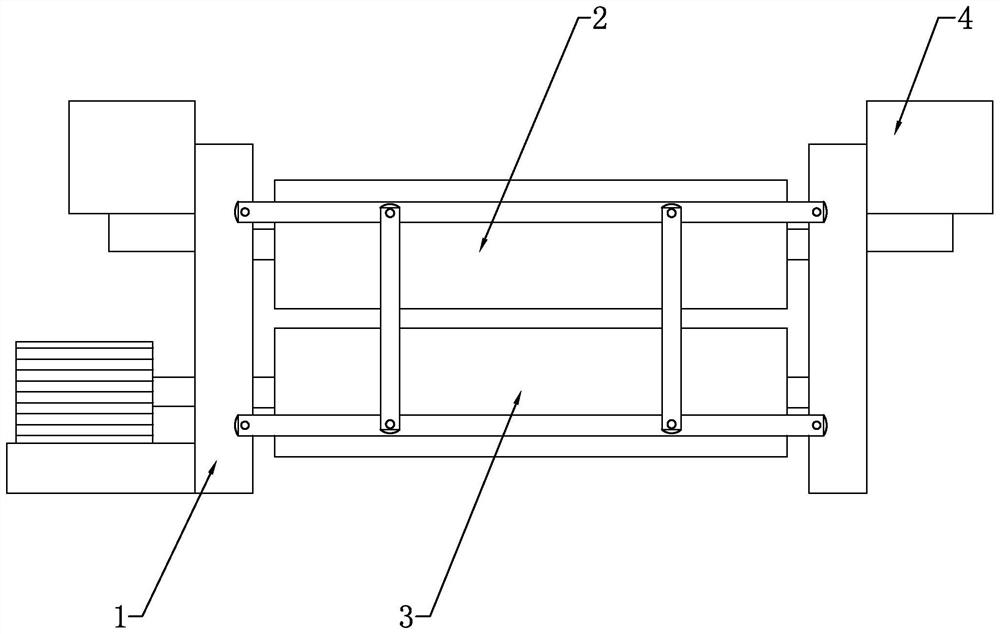

[0073] see Figure 1-Figure 2 , this embodiment discloses a helical-toothed edge-cutting V-belt processing equipment, including a calender, the calender includes: a body 1; an upper pressing roller 2; it is arranged on the upper part of the body 1; The upper pressure roller 2 cooperates to press and extend the rubber; two comprehensive adjustment components 4 are respectively connected with the two ends of the upper pressure roller 2 to adjust the position and angle of the upper pressure roller 2; wherein, when the upper pressure roller 2 When the position of the roller is changed within a certain range, it can still cooperate with the lower pressing roller 3.

[0074] In this embodiment, both the upper pressure roller 2 and the lower pressure roller 3 are rotatably arranged on the body 1, there is a gap for the rubber to pass through between the upper pressure roller 2 and the lower pressure roller 3, and the upper pressure roller 2 and the lower pressure roller 3 The coordi...

Embodiment 2

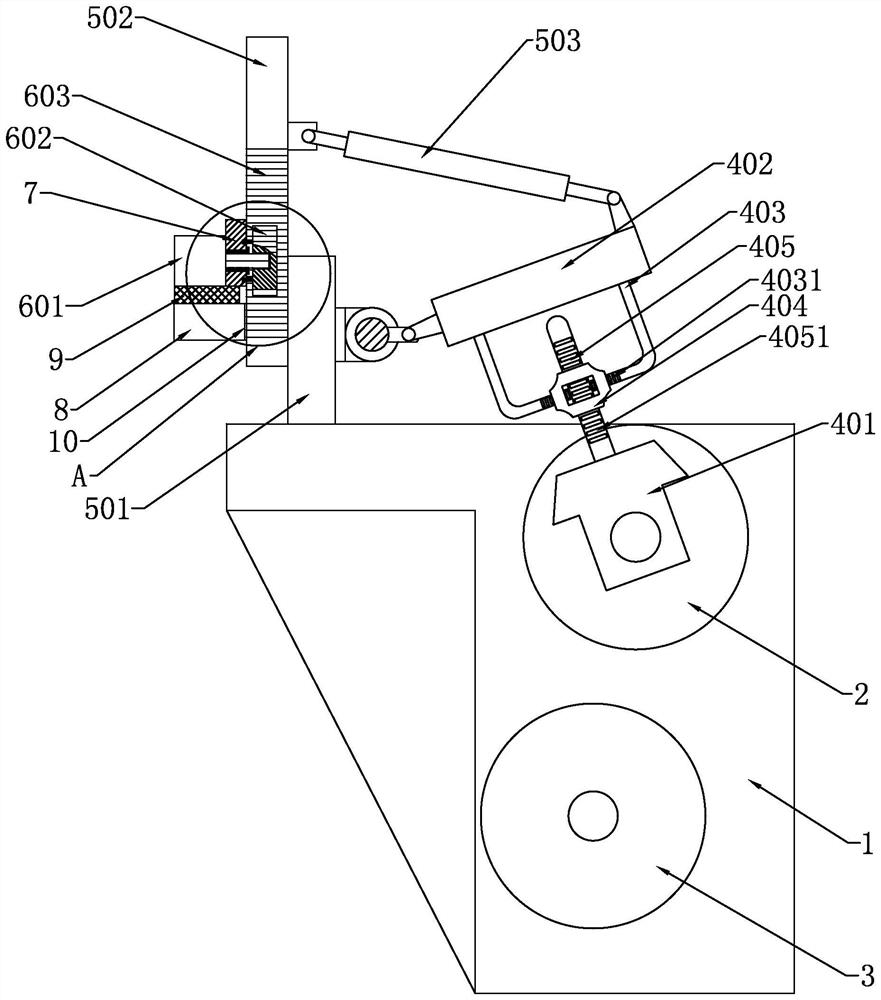

[0078] In this embodiment, in addition to including the characteristic structures of the previous embodiments, each integrated adjustment assembly 4 further includes: a mounting frame 401, which is connected to the end of the upper pressing roller 2; a four-direction translation assembly, which can drive the mounting frame 401 translates on a first path and a second path that are perpendicular to each other; an angle adjustment component, which can adjust the angle of the four-direction translation component.

[0079] In this embodiment, the four-direction translation assembly can drive the mounting frame 401 to translate in four directions, namely, the opposite directions of the upper side, the lower side, the left side, and the right side. The first path and the second path are not perpendicular to each other. It is required that the two must be 90 degrees from each other, and the angle adjustment component can adjust the vertical angle of the four-way translation component. ...

Embodiment 3

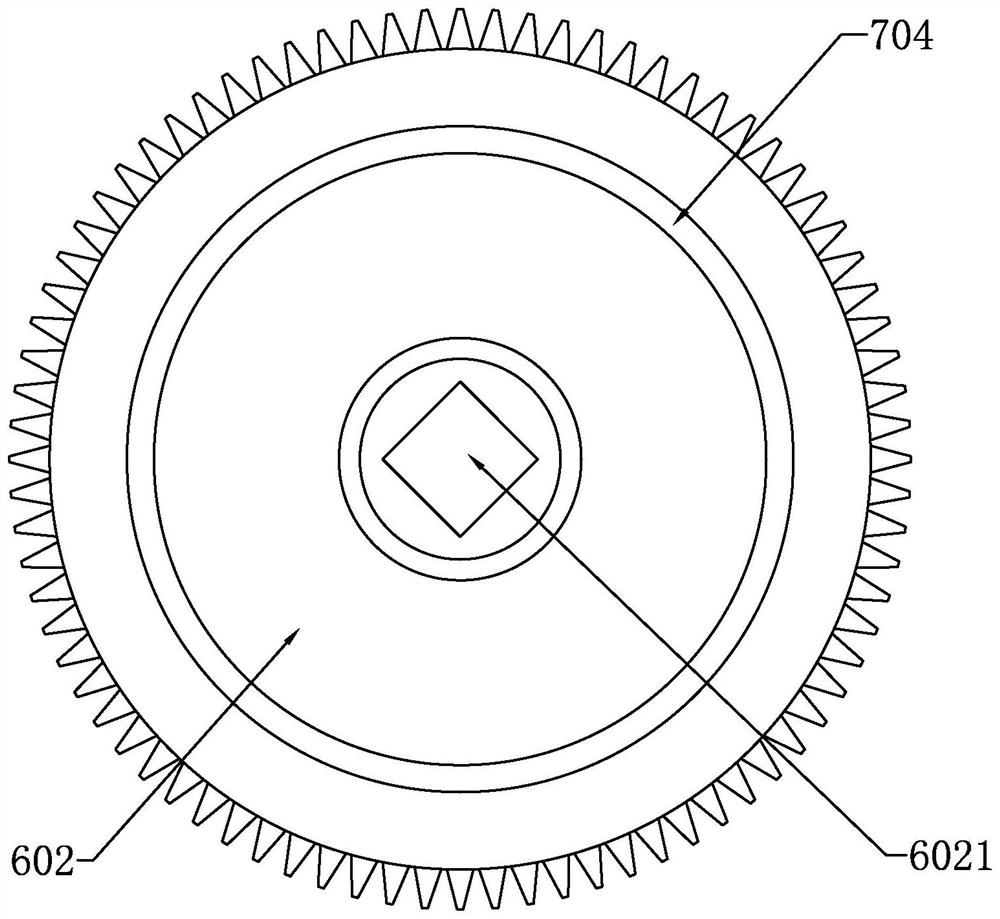

[0083] see figure 2 , in this embodiment, in addition to including the characteristic structure of the previous embodiment, a structure of the four-way translation assembly is further disclosed, and the specific four-way translation assembly includes: an adjustment frame 402, which is connected with the angle adjustment assembly; the connecting frame 403, which is U-shaped, its two ends are fixed on the adjusting frame 402, and the middle section is provided with a first track 4031; the adjusting sleeve 404, which includes a first sliding part 4041 and a second sliding part 4042, which can pass through the first The sliding part 4041 is slidably connected to the first track 4031 ; the movable bar 405 is connected to the mounting frame 401 at its first end, and has a second track 4051 at its second end, and the adjusting sleeve 404 is slidably slidable through the second sliding part 4042 Connected to the second rail 4051; the first driving member, which is used to drive the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com