Polylactic acid bio-based functional wrap yarn for sweater and preparation method thereof

A bio-based, polylactic acid technology, applied in the field of covered yarn, can solve the problems of easy deformation and static electricity of wool fiber, and achieve the effects of avoiding skin discomfort, improving easy deformation, and solving static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

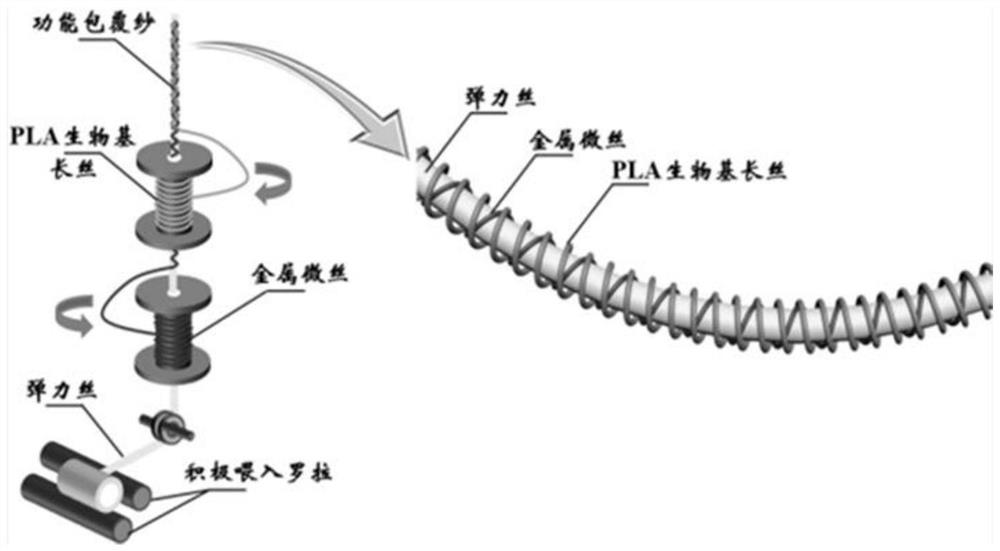

Method used

Image

Examples

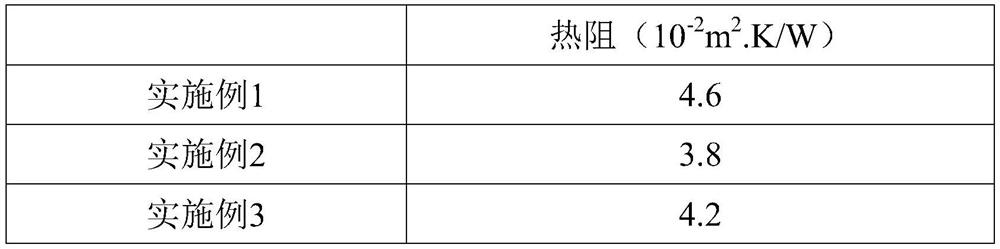

Embodiment 1

[0037] 1. According to the method of patent CN201610827052.5, PLA bio-based filament is prepared by blending polylactic acid fiber and wool fiber, and the weight ratio of polylactic acid fiber and wool fiber is 20:80.

[0038] 2. The weight percentage of each component in the covered yarn is:

[0039] Nylon stretch yarn 70%

[0040] Metal microwires 3%

[0041] PLA biobased filament 27%.

[0042] 3. Preparation of covered yarn: The outer covered yarn on the hollow spindle tube is unwound from the spindle tube and moves upward through the yarn guide hook together with the core yarn. The spindles rotate together at a high speed under the drive of the spindle belt, which drives the outer covering yarn wound on the spindle tube to rotate together to form the winding of the outer covering yarn to the core yarn to obtain the covering yarn. Wherein, the outer covering yarn includes a first outer covering yarn and a second outer covering yarn, the first outer covering yarn is metal...

Embodiment 2

[0044] 1. According to the method of patent CN201610827052.5, PLA bio-based filament is prepared by blending polylactic acid fiber and wool fiber, and the weight ratio of polylactic acid fiber and wool fiber is 30:70.

[0045] 2. The weight percentage of each component in the covered yarn is:

[0046] Nylon stretch yarn 65%

[0047] Metal microwires 3%

[0048] PLA biobased filament 32%.

[0049] 3. Preparation of covered yarn: The outer covered yarn on the hollow spindle tube is unwound from the spindle tube and moves upward through the yarn guide hook together with the core yarn. The spindles rotate together at a high speed under the drive of the spindle belt, which drives the outer covering yarn wound on the spindle tube to rotate together to form the winding of the outer covering yarn to the core yarn to obtain the covering yarn. Wherein, the outer covering yarn includes a first outer covering yarn and a second outer covering yarn, the first outer covering yarn is metal...

Embodiment 3

[0051]1. According to the method of patent CN201610827052.5, PLA bio-based filament is prepared by blending polylactic acid fiber and wool fiber, and the weight ratio of polylactic acid fiber and wool fiber is 25:75.

[0052] 2. The weight percentage of each component in the covered yarn is:

[0053] Polyester Stretch Yarn 62%

[0054] Metal microwires 3%

[0055] PLA biobased filament 35%.

[0056] 3. Preparation of covered yarn: The outer covered yarn on the hollow spindle tube is unwound from the spindle tube and moves upward through the yarn guide hook together with the core yarn. The spindles rotate together at a high speed under the drive of the spindle belt, which drives the outer covering yarn wound on the spindle tube to rotate together to form the winding of the outer covering yarn to the core yarn to obtain the covering yarn. Wherein, the outer covering yarn includes a first outer covering yarn and a second outer covering yarn, the first outer covering yarn is me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com