Automatic dismounting and mounting device and method for rotational molding equipment mold

A mold and equipment technology, applied to chemical instruments and methods, cleaning methods using tools, cleaning methods using liquids, etc., to increase efficiency, increase disassembly speed, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

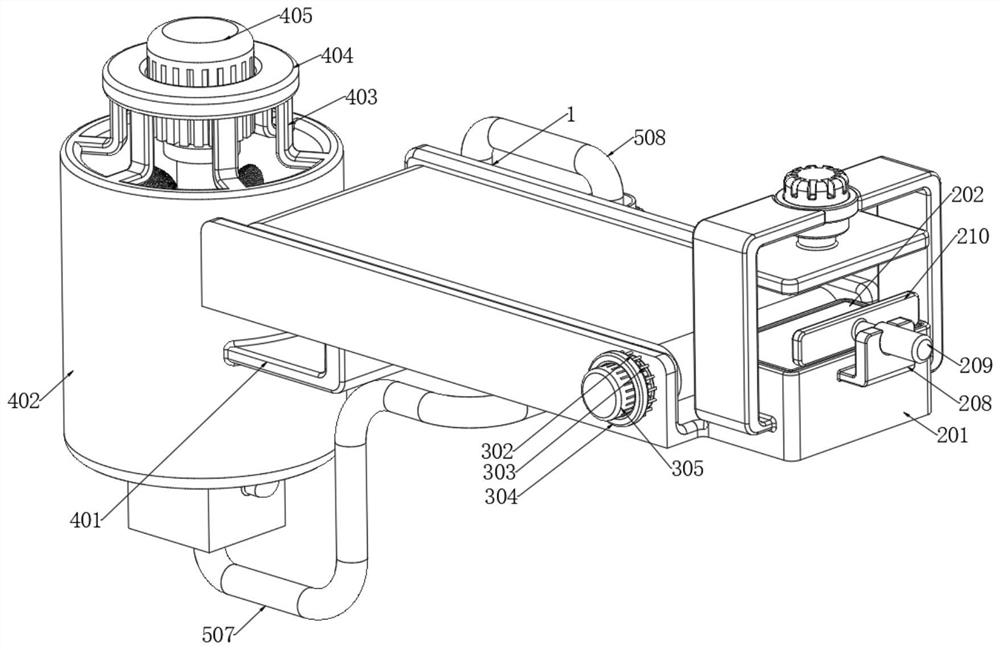

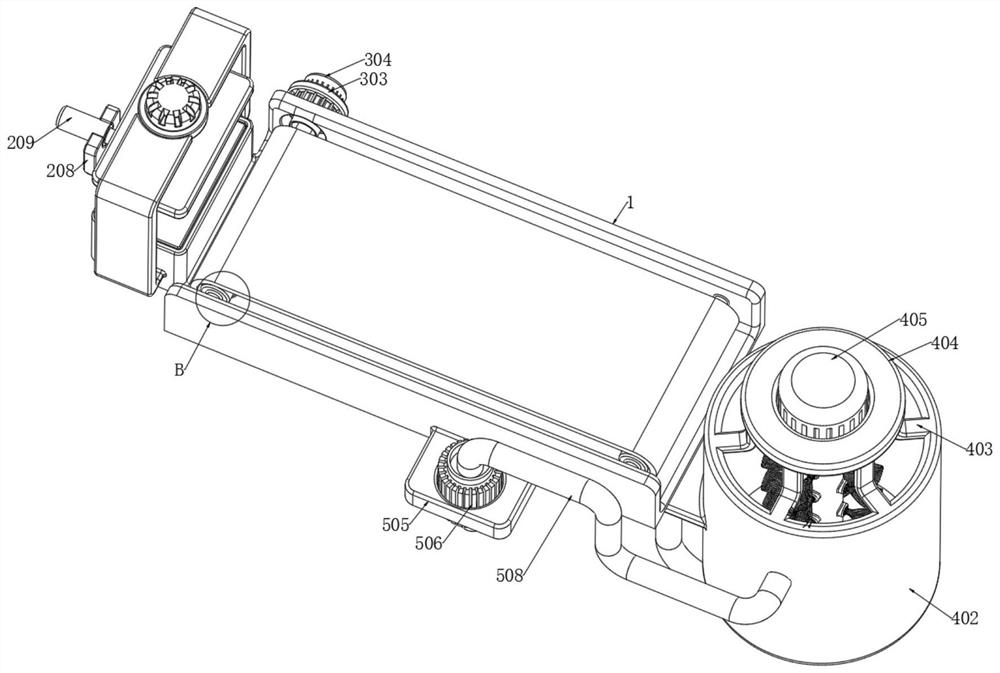

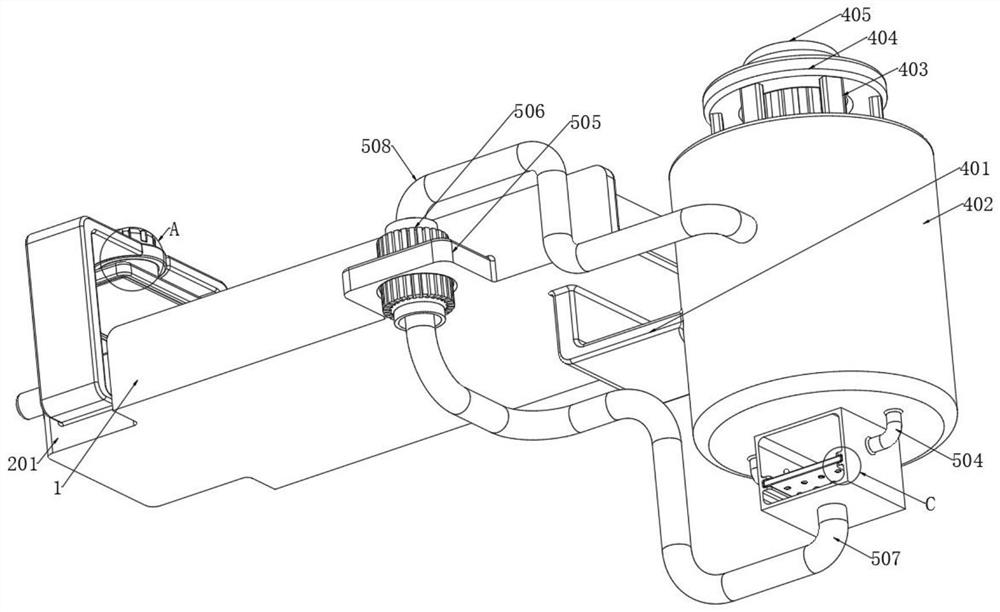

[0035] The effect achieved by the whole mechanism is: first install the device to the designated work area, place the mold to be disassembled on the junction box 201, and make one side fully contact with the electromagnetic panel A202, at this time start and fix it on the connecting ring The hydraulic rod 205 in A204 drives the top plate 206 to move towards the top of the mold, and finally the electromagnetic panel B207 is fully in contact with the top of the mold, and the electromagnetic panel A202 and the electromagnetic panel B207 are energized, and the strong magnetic attraction generated inside them will be tightly adsorbed On the metal mould, start the hydraulic rod 205 again to separate the upper and lower parts of the mould, disconnect the power supply in the electromagnetic panel A202 and the electromagnetic panel B207, and then start the electric telescopic rod 209 on the L-shaped metal frame A208 , drive the push plate 210 to move forward, and continue to push the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com