Polymer electrolyte, preparation method thereof and application of polymer electrolyte in wide-temperature-range and high-rate solid-state lithium battery

A polymer and electrolyte technology, used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, organic electrolytes, etc., can solve the problems of inability to realize fast charging and fast discharging of batteries, limited application scenarios, and inability of batteries to work, and achieve wide electrochemical performance. Stable window, high ionic conductivity, cost-effective and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

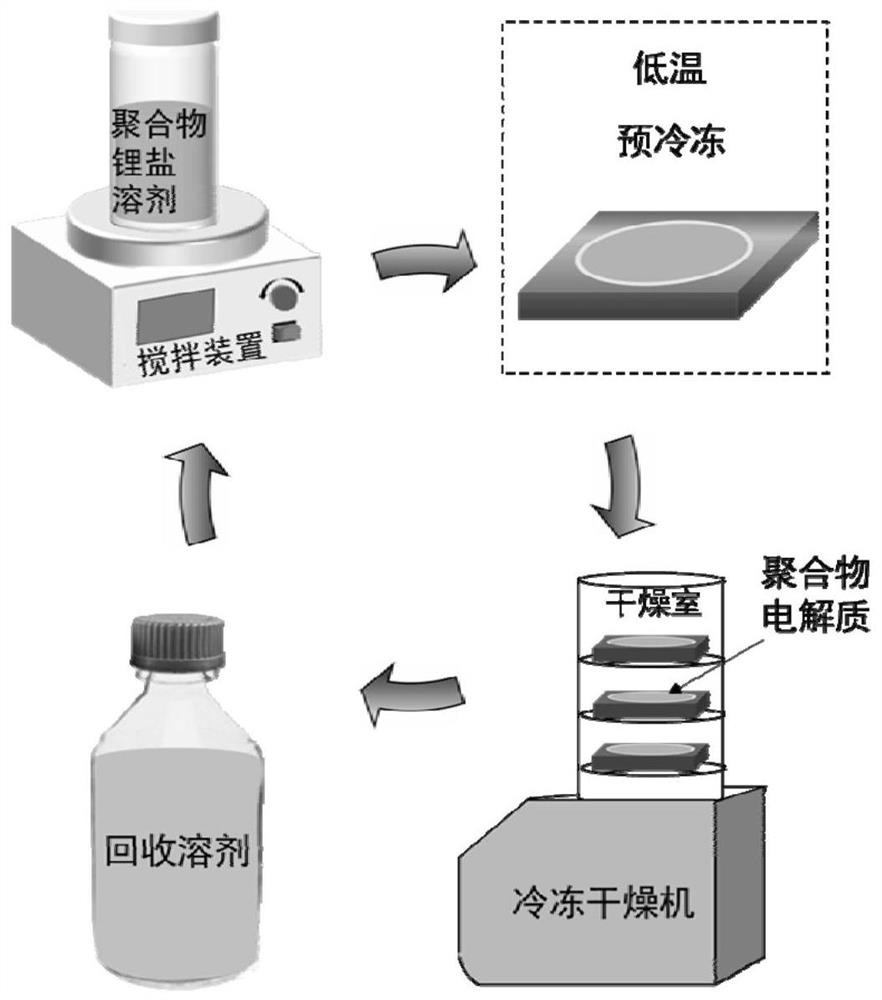

[0031] The present embodiment is the preparation of a polymer electrolyte, the process is as follows:

[0032] The molecular weight of 400,000 PVDF-HFP and LiTFSI were dissolved in a dimethyl sulfoxide solvent, stirred for 24 hours to obtain a homogeneous solution. Among them, PVDF-HFP accounts for a mass fraction of 7.9wt.% in solution, and LiTFSI weight accounts for 40wt.% of the total mass of LiTFSI and PVDF-HFP. Subsequently, the homogeneous solution is transferred to a PTFE substrate, frozen at -18 °C for 24 hours, and frozen-dried in a freeze dryer for 48 hours after removal to obtain the polymer electrolyte.

[0033] Figure 1 Schematic diagram of polymer electrolyte preparation and solvent recovery process is shown.

Embodiment 2

[0035] The present embodiment is the preparation of a polymer electrolyte, the process is as follows:

[0036] The molecular weight of 500,000 PVDF and LiTFSI were dissolved in N-methylpyrrolidone solvent, stirred for 24 hours to obtain a homogeneous solution. Among them, PVDF accounts for a mass fraction of 7.9wt.% in solution, and LiTFSI weight accounts for 40wt.% of the total mass of LiTFSI and PVDF. Subsequently, the homogeneous solution is transferred to a PTFE substrate, frozen at -30 ° C for 24 hours, and frozen-dried in a freeze dryer for 48 hours after removal to obtain the polymer electrolyte.

Embodiment 3

[0038] The present embodiment is the preparation of a polymer electrolyte, the process is as follows:

[0039]The PAN and LiFSI with a molecular weight of 150,000 were dissolved in a dimethyl sulfoxide solvent and stirred for 24 hours to obtain a homogeneous solution. Among them, PAN accounts for a mass fraction of 5wt.% in the solution, and LiFSI weight accounts for 30wt.% of the total mass of LiFSI and PAN. Subsequently, the homogeneous solution is transferred to a PTFE substrate, frozen at -18 °C for 24 hours, and frozen-dried in a freeze dryer for 48 hours after removal to obtain the polymer electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com