Combined roller structure, roller, high-end bearing and high-end equipment

A roller and bearing technology, used in high-end equipment, rollers, combined roller structures, and high-end bearings, can solve problems such as poor self-cleaning performance, aggravated grinding, and shortened life, to reduce weight, increase service life, increase effect on overall lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

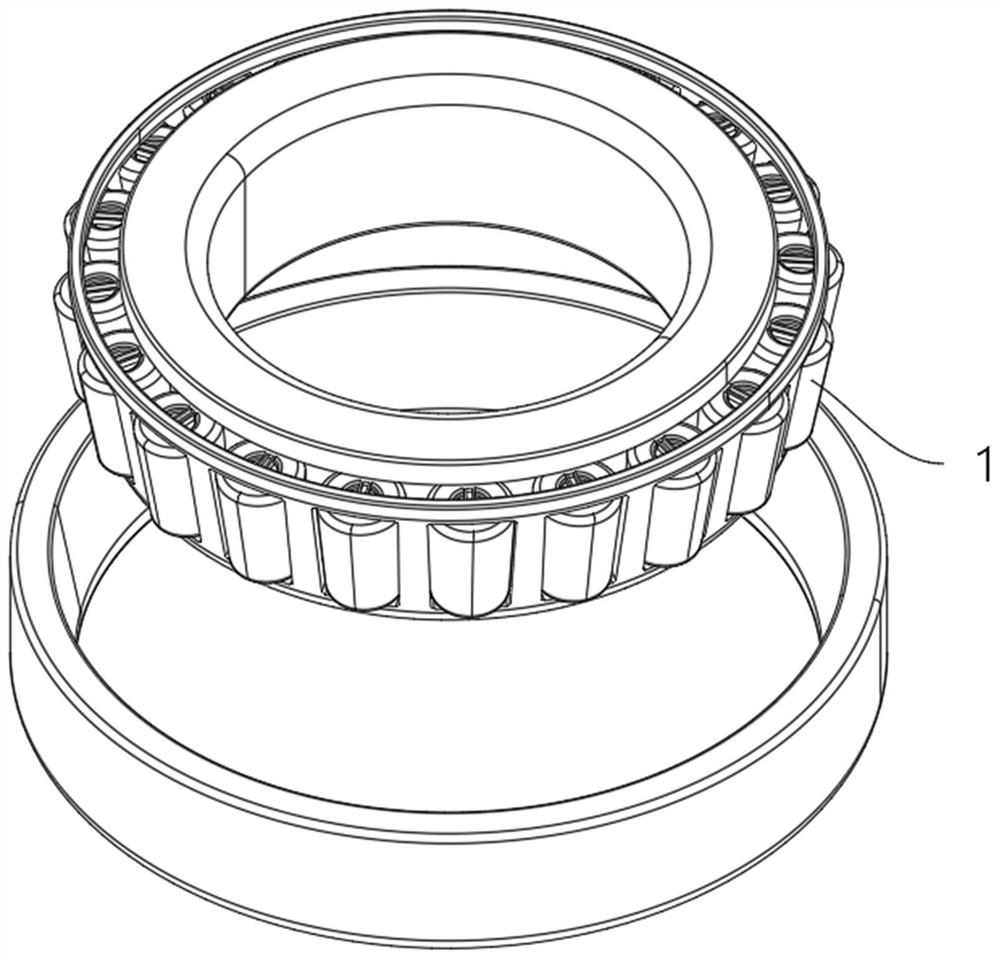

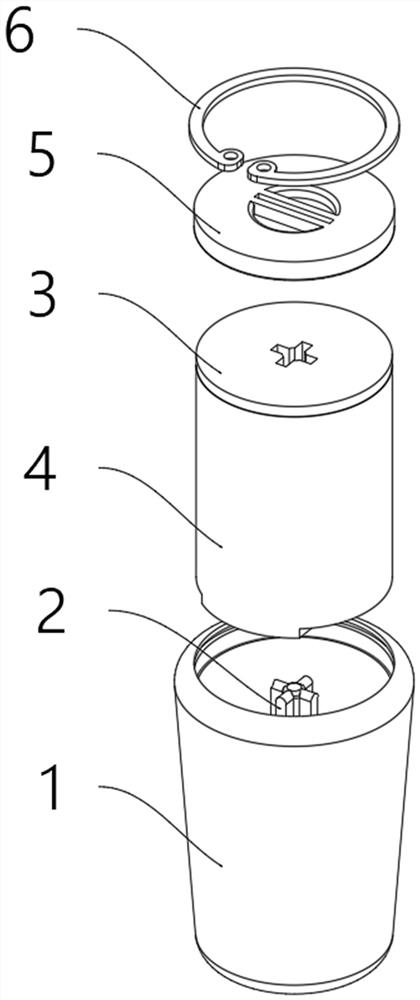

[0043] like Figure 1-3 As shown, the combined roller structure, compared with the prior art, is unique in that: it is used as a constituent part of the bearing roller; it has a roller shell 1, a cross column 2, a combined piece 3, a clip 5 and a clip spring 6 The main body of the roller shell 1 is a tapered trapezoidal shell structure, and the top inner side of the roller shell 1 is a hollow structure; the bottom side of the roller shell 1 is provided with two inclined grooves 101, and the two inclined grooves 101 are symmetrical; The interval between the bottom end openings of the two groups of inclined grooves 101 is greater than the interval between the top end openings of the two groups of inclined grooves 101;

[0044] The inner side of the roller shell 1 is provided with a shoulder structure, and the upper position of the shoulder structure is provided with a spring groove 102;

[0045] The cross column 2 is integrally arranged in the middle of the inner side of the ro...

Embodiment 2

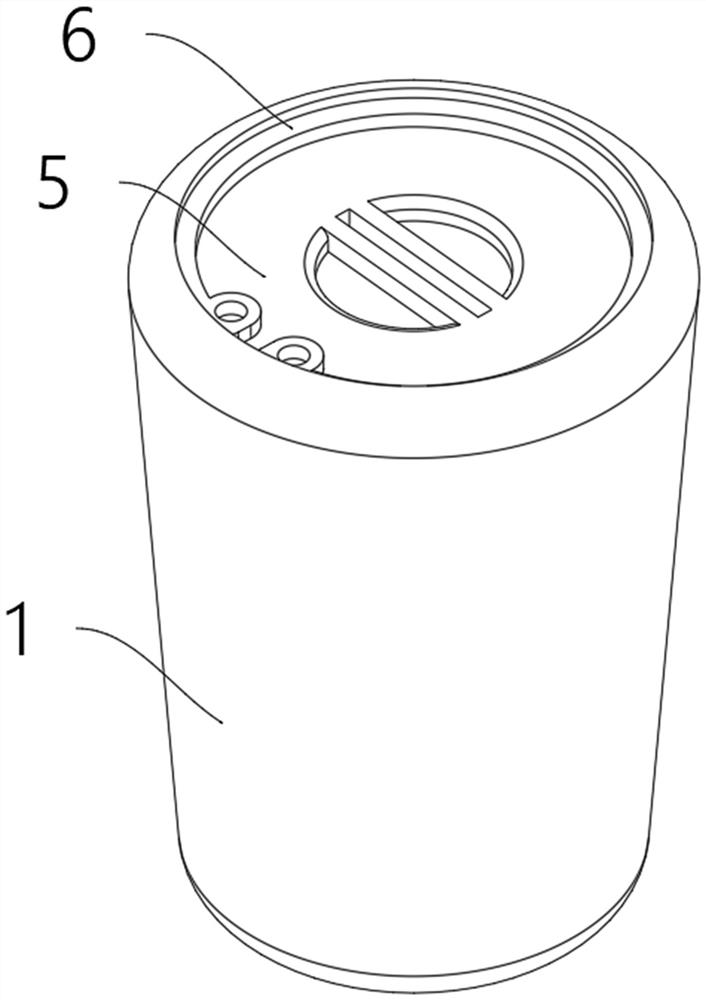

[0052] like Figure 8 As shown in the figure, the cylindrical casing 4 is unique compared with the prior art in that it is designed to fit the roller shell 1 and the rolling diamond column 301 described in Embodiment 1, and the middle of the cylindrical casing 4 runs through the upper and lower ends. A diamond-shaped groove 402 is opened.

[0053] Embodiment 2-1, based on the technical solution of Embodiment 2, a further optional technical solution: the material of the columnar container 4 is a foamed sponge with a shrinkage rate exceeding five times; the bottom of the columnar container 4 is opened There is an oil channel 401 .

[0054] Embodiment 2-2, based on the technical solution of Embodiment 2, a further optional technical solution: the oil channel 401 is opened around, and both ends of the oil channel are connected to the top ends of the chute 101 .

[0055] Embodiment 2-3, based on the technical solution of Embodiment 2, a further optional technical solution: the cyli...

Embodiment 3

[0057] like image 3 The bottom of the combination sheet 3 is provided with a docking slot 302 in the middle of the bottom of the diamond-shaped column, which is slidably arranged outside the docking column 2. The roller shell 1 described in Example 1 is designed to include a diamond-shaped column 301 and a butt groove 302;

[0058] The shapes of the rhombus column 301 and the butt groove 302 are kept the same;

[0059] The diamond-shaped column 301 is arranged in the middle of the bottom of the composite sheet 3, and the outer surface of the diamond-shaped column 301 is a smooth surface;

[0060] The lengths of the upper and lower corners of the diamond-shaped column 301 are the same;

[0061] like Figure 7 As shown, a diamond-shaped column 301 is arranged in the middle of the bottom of the composite sheet 3, and a docking slot 302 is arranged in the middle of the bottom of the diamond-shaped column 301;

[0062] The diamond-shaped column 301 can cooperate with the docki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com