Uniform tensioning and laying equipment for large-gradient long-distance slope geocell

A geocell, long-distance technology, used in soil protection, infrastructure engineering, construction, etc., can solve the problems of fixed geocells drawn into a mesh, slow construction progress, complicated steps, etc., and achieve uniform force. , Improve the bearing capacity, the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

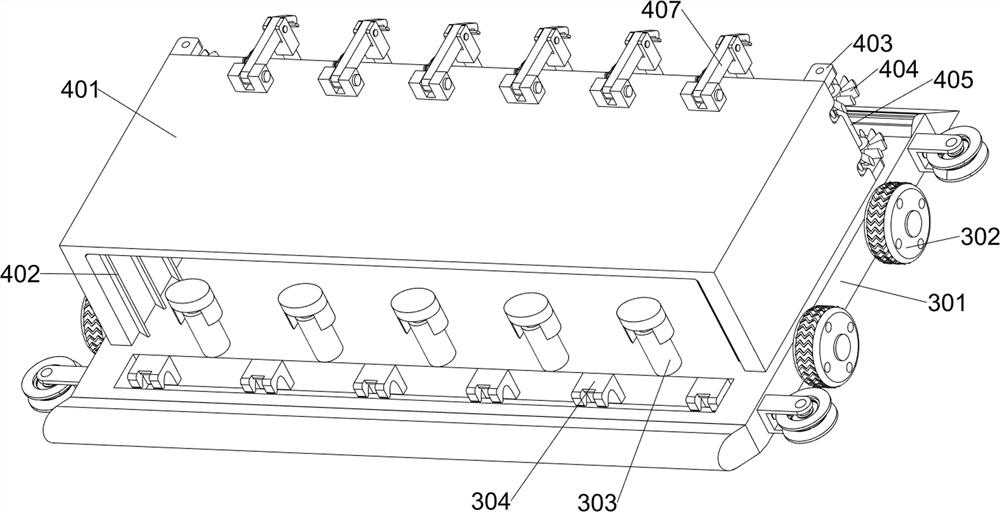

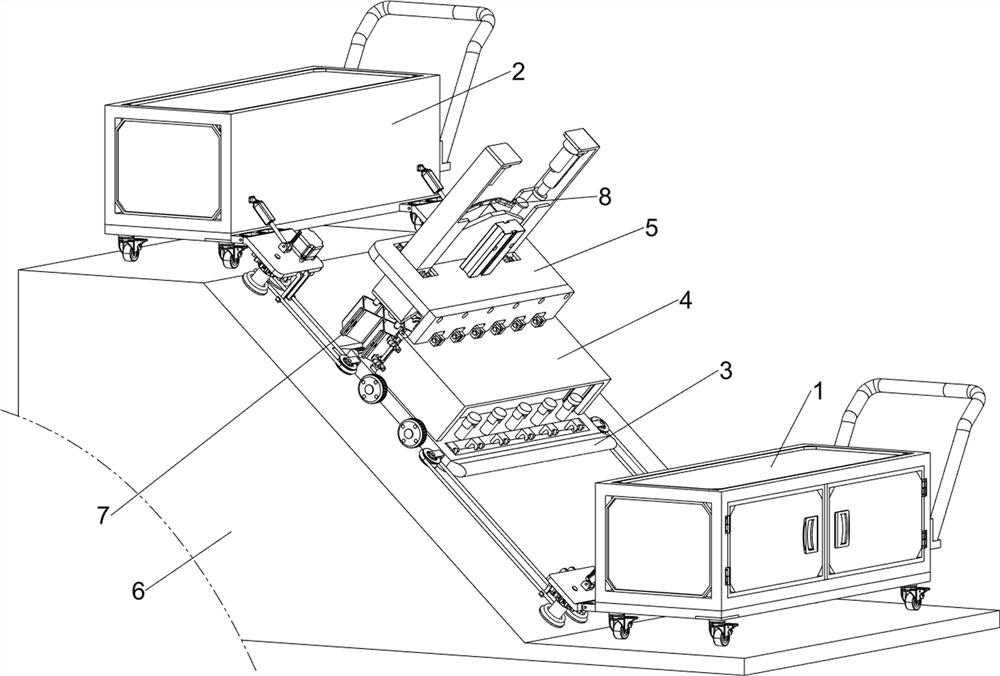

[0038] A large-slope and long-distance slope geocell uniform tensioning and laying equipment, such as Figure 1-2 As shown, it includes a first cart 1, a second cart 2, a power system 3, a pull-out system 4 and a spreading system 5; a power system 3 is connected between the first cart 1 and the second cart 2; A pull-out system 4 is connected to the upper surface of the power system 3 ; a spreader system 5 is connected to the pull-out system 4 .

[0039] Working principle: When using the large-slope and long-distance slope geocell uniform tension laying equipment, hereinafter referred to as the geocell laying equipment, the operator transports the geocell laying equipment to the slope protection 6, and then the geocell laying equipment Assemble, that is, the operator places the first cart 1 on the bottom of the slope protection 6, and the second cart 2 on the slope top of the slope protection 6, and then the operator pulls out the power system 3 and the power system of the geoc...

Embodiment 2

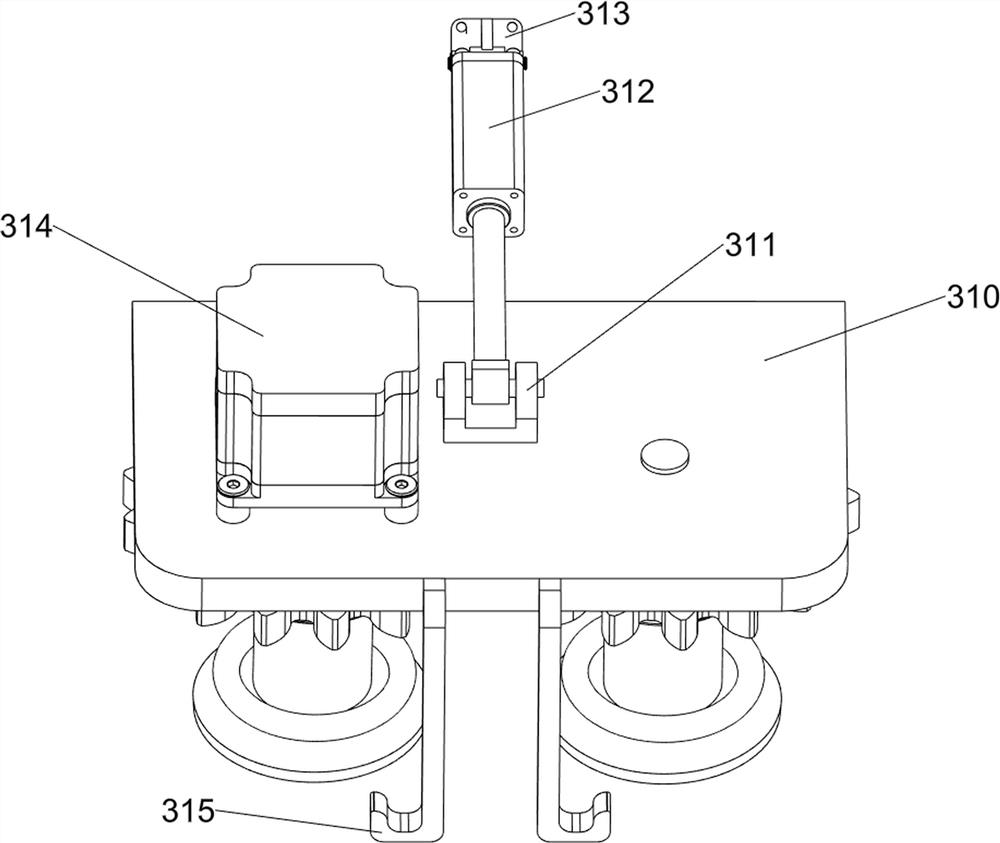

[0041] On the basis of Example 1, as figure 1 and Figure 4-16 As shown, the power system 3 includes a first mounting plate 301, a wheel 302, a fixing column 303, a fixing buckle 304, a top plate 305 and a power assembly; the right part of the first cart 1 is connected with two power assemblies, and the two power assemblies The left part of the second cart 2 is connected with two other power components, and the other two power components are distributed symmetrically in the front and rear; a first mounting plate 301 is connected between the four power components; the first mounting plate 301 The front part and the rear part are respectively connected with two wheels 302 through rotating shafts, and the two wheels 302 are symmetrically distributed on the left and right; the right part of the upper surface of the first installation plate 301 is fixedly fixed with five fixed columns 303 at equal distances; the first installation plate The inside of 301 is provided with a first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com