Bio-based solvent-resistant plasticizer and preparation method thereof

A solvent-resistant and plasticizer-resistant technology, which is applied in the field of bio-based solvent-resistant plasticizers and their preparation, can solve problems such as poor mechanical properties and processing properties, large pollution, and intolerant solvents, so as to improve compatibility and improve Flame retardant performance, good plasticity and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of a polyethylene resin containing a bio-based solvent-resistant plasticizer, comprising the following steps:

[0060] Accurately weigh 70g polyethylene and 30g bio-based solvent-resistant plasticizer and mix them evenly, then pour the mixture into a twin-screw extruder and melt it twice to prepare a blend. The temperature in each zone of the twin-screw extruder is set to 140 °C. °C, 175 °C, 190 °C, 190 °C, 190 °C; then the blend is pulverized into pellets by a powerful pulverizer, and then the pellets are injected into pellets by a micro injection molding machine at a barrel temperature of 165 °C and a melting time of 5 minutes. Polyethylene resin plastic sheet.

[0061] The bio-based solvent-resistant plasticizer is a mixture of modified isosorbide dioleate and tris(ethyl butyrate) isocyanurate in a mass ratio of 1:3.

[0062] The preparation method of the modified isosorbide dioleate comprises the following steps:

[0063] S1 Mix 100g of oleic ...

Embodiment 2

[0069] A preparation method of a polyethylene resin containing a bio-based solvent-resistant plasticizer, comprising the following steps:

[0070] Accurately weigh 70 g of polyethylene and 30 g of bio-based solvent-resistant plasticizer and mix them evenly, then pour the mixture into a twin-screw extruder and melt it twice to prepare a blend. The temperature in each zone of the twin-screw extruder is set to 140 °C. °C, 175 °C, 190 °C, 190 °C, 190 °C; then the blend is pulverized into pellets with a powerful pulverizer, and then the pellets are injected into pellets by a micro injection molding machine at a barrel temperature of 165 °C and a melting time of 5 minutes. Polyethylene resin plastic sheet.

[0071] The bio-based solvent-resistant plasticizer is isosorbide diepoxyoleate.

[0072]The preparation method of described diepoxy oleate isosorbide, comprises the following steps:

[0073] S1 Mix 100g of oleic acid with 30g of isosorbide, and after mixing evenly, heat to 130...

Embodiment 3

[0076] A preparation method of a polyethylene resin containing a bio-based solvent-resistant plasticizer, comprising the following steps:

[0077] Accurately weigh 70g polyethylene and 30g bio-based solvent-resistant plasticizer and mix them evenly, then pour the mixture into a twin-screw extruder and melt it twice to prepare a blend. The temperature in each zone of the twin-screw extruder is set to 140 °C. °C, 175 °C, 190 °C, 190 °C, 190 °C; then the blend is pulverized into pellets by a powerful pulverizer, and then the pellets are injected into pellets by a micro injection molding machine at a barrel temperature of 165 °C and a melting time of 5 minutes. Polyethylene resin plastic sheet.

[0078] The bio-based solvent-resistant plasticizer is modified isosorbide dioleate.

[0079] The preparation method of the modified isosorbide dioleate comprises the following steps:

[0080] S1 Mix 100g of oleic acid with 30g of isosorbide, and after mixing evenly, heat to 130°C in a n...

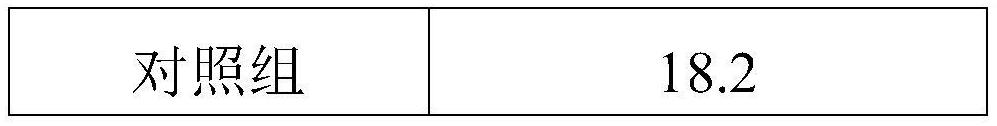

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com