Biomass-based graphene material and preparation method thereof

A biomass and graphite-based technology, applied in the field of carbon materials, can solve the problems of restricting large-scale application, small lateral size, hindering mass production, etc., and achieve good economic benefits, reduce the use of materials, and be easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of biomass-based graphene material, its preparation method comprises the following steps:

[0030] 1) biomass and ferric chloride hydrate are mixed and pulverized to obtain pulverized material;

[0031] Among them, biomass includes lignocellulosic bio-wastes such as wood chips, leaves, and crop straw; the mass ratio of biomass and ferric chloride hydrate is 2:1-1:2; the crushing machines used include crushers, mixers, ball mills, Wall breaker, soymilk maker, juicer, food processor, powder mixer, pulverizer or grinder; crushing time is 1-60min;

[0032] Preferably, the pulverization process can be carried out in multiple times, that is, shear pulverization and standing are alternately performed to prevent the pulverizer from being overloaded and the motor from overheating. At the same time, opening the lid and standing still can ensure FeCl 3 ·6H 2 O fully adsorbs the water vapor in the air and completely impregnates the biomass.

[0033] 2) The pulverized mat...

Embodiment 1

[0041] A wood chip-derived biomass-based graphene, its preparation method comprises the following steps:

[0042] 1) Combine the same mass of sawdust with FeCl 3 ·6H 2 O was added to the Aux HX-PB1250 wall-breaking food processor, mixed and pulverized, with a concentration of 4.5 × 10 4 After shearing and pulverizing at rpm for 2min, turn on the pulverizer and let it stand for 15min, and repeat the process 20 times to obtain pulverized material;

[0043] 2) The pulverized material is placed in a tube furnace, and pre-carbonized at 450°C for 2h under nitrogen protection;

[0044] 3) Keep a nitrogen environment, at a heating rate of 10°C / min, heat to 1000°C and pyrolyze for 3 hours, and obtain a black pyrolysis product powder after cooling;

[0045] 4) The pyrolysis product powder is placed in 6mol / L hydrochloric acid and dipped for 3 times, and the dipping time is 10min each time;

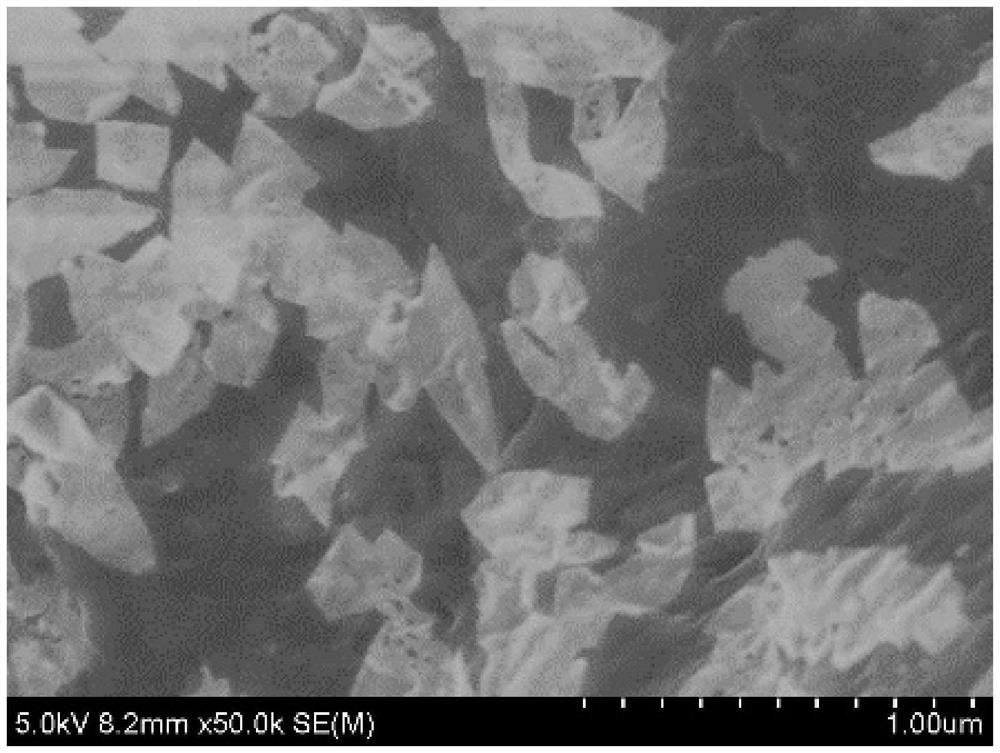

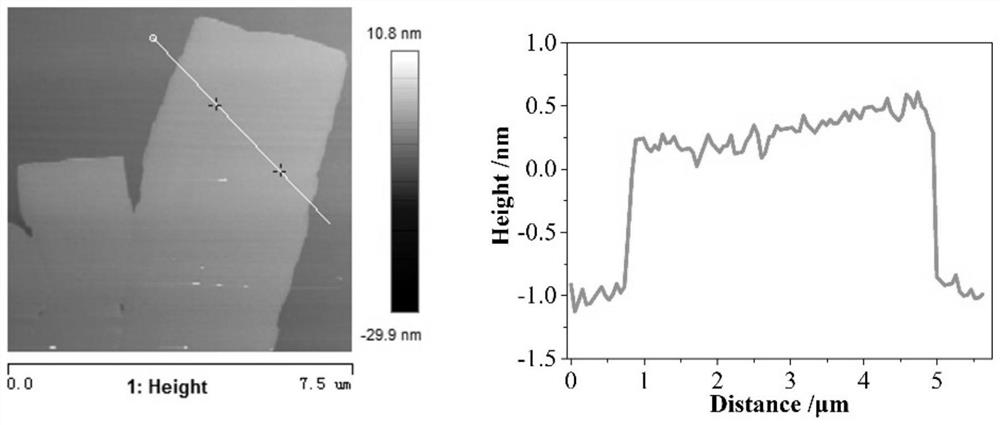

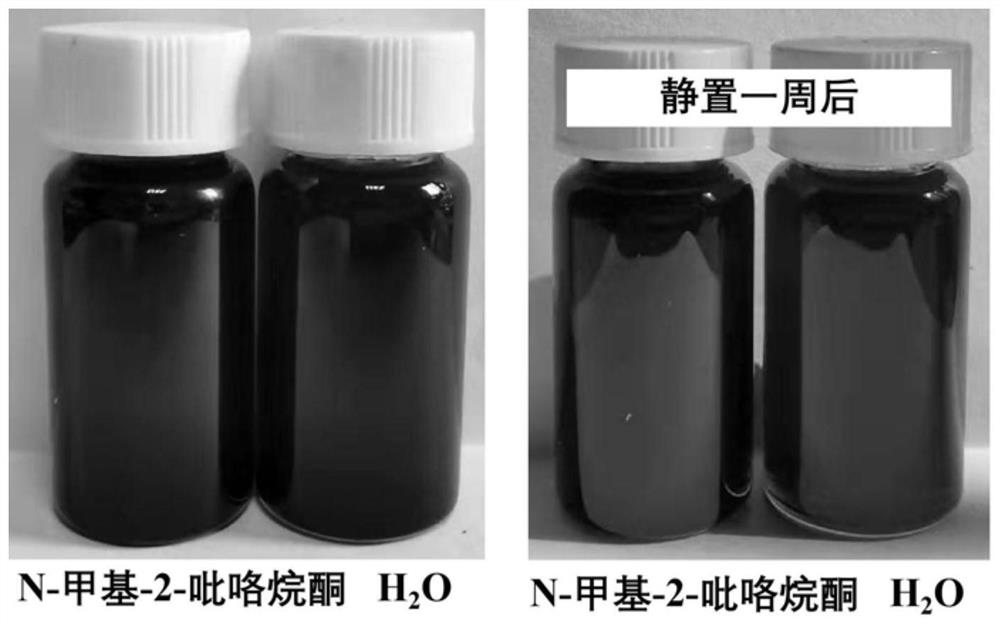

[0046]5) After washing with deionized water until neutral, the wood chip-derived biomass-bas...

Embodiment 2

[0055] A kind of biomass-based graphene material, its preparation method comprises the following steps:

[0056] 1) Combine the same mass of sawdust with FeCl 3 ·6H 2 O is added together to Baijie BJ-150 stainless steel pulverizer for mixing and pulverization, with 4.5 × 10 4 After shearing and pulverizing at rpm for 2min, turn on the pulverizer and let it stand for 15min, and repeat the process 20 times to obtain pulverized material;

[0057] 2) The pulverized material is placed in a tube furnace, and pre-carbonized at 450°C for 2h under nitrogen protection;

[0058] 3) Keep a nitrogen environment, at a heating rate of 10°C / min, heat to 1000°C and pyrolyze for 3 hours, and obtain a black pyrolysis product powder after cooling;

[0059] 4) The pyrolysis product powder is placed in 6mol / L hydrochloric acid and dipped for 3 times, and the dipping time is 10min each time;

[0060] 5) After washing with deionized water until neutral, the biomass-based graphene material is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pyrolysis temperature | aaaaa | aaaaa |

| Pyrolysis temperature | aaaaa | aaaaa |

| Hall mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com