Preparation method of ultrathin titanium strip for bipolar plate of hydrogen fuel cell

A fuel cell and bipolar plate technology, which is used in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems that the mechanical properties and batch stability of products are difficult to meet the engineering application of hydrogen fuel cell titanium bipolar plates. , to achieve the effect of reducing the conduction resistance of the bipolar plate to current and heat, high anti-corrosion performance, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

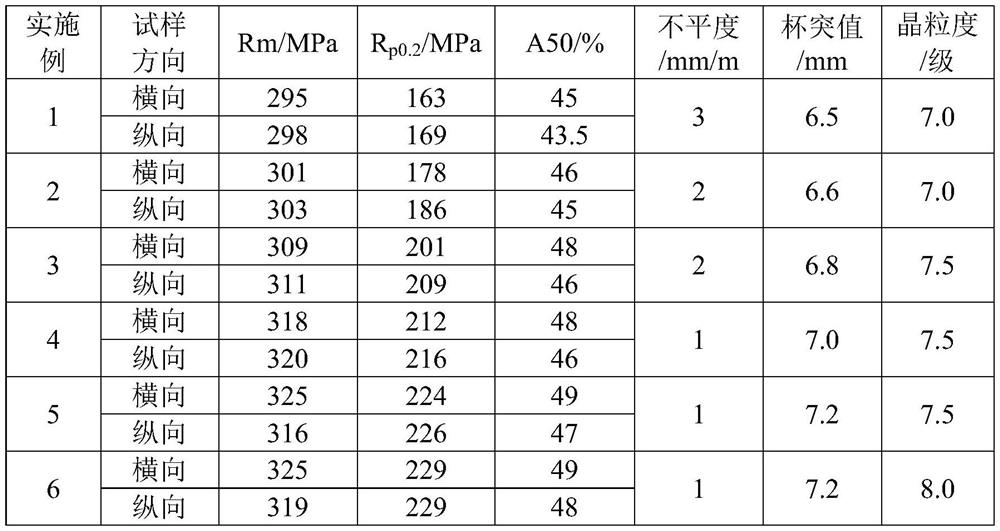

Examples

Embodiment 1

[0039]S1-1. Select grade 0 small particle sponge titanium as the raw material, wherein the mass percentage of each impurity element in the sponge titanium is: Fe: 0.015wt%, O: 0.035wt%; the Brinell hardness HBW of the sponge titanium is 90N / mm 2 ;

[0040] S1-2, the sponge titanium obtained in step S1-1 is smelted twice in a vacuum consumable electric arc furnace to obtain a pure titanium ingot; wherein, the mass percentage composition of each element in the pure titanium ingot is: Fe: 0.03wt% , C: 0.02wt%, N: 0.02wt%, H: 0.006wt%, O: 0.045wt%, the balance is Ti;

[0041] S2, slab forging:

[0042] The pure titanium ingot obtained in step S1-2 is heated to 900 ° C, forging is carried out after holding for 3 hours, and then the forging defects and oxide scale on the surface of the pure titanium ingot after forging are removed by machining, and finally the surface finishing treatment is performed to control the rough surface of the slab. The degre...

Embodiment 2

[0057] A preparation method of an ultra-thin titanium strip for a hydrogen fuel cell bipolar plate, comprising the following steps:

[0058] S1, ingot smelting:

[0059] S1-1. Select grade 0 small particle sponge titanium as the raw material, wherein the mass percentage of each impurity element in the sponge titanium is: Fe: 0.014wt%, O: 0.034wt%; the Brinell hardness HBW of the sponge titanium is 88N / mm 2 ;

[0060] S1-2, press the sponge titanium obtained in step S1-1 into a single electrode, then weld the single electrode with tungsten argon arc welding, and finally use the vacuum consumable electric arc furnace to carry out the welding of the single electrode after the welding is completed. Secondary smelting to obtain a pure titanium ingot; wherein, the mass percentage composition of each element in the pure titanium ingot is: Fe: 0.026wt%, C: 0.018wt%, N: 0.015wt%, H: 0.0059wt%, O: 0.042wt%, the balance is Ti; among them, the vacuum consumable electric arc furnace curr...

Embodiment 3

[0077] A preparation method of an ultra-thin titanium strip for a hydrogen fuel cell bipolar plate, comprising the following steps:

[0078] S1, ingot smelting:

[0079] S1-1. Select grade 0 small particle sponge titanium as the raw material, wherein the mass percentage of each impurity element in the sponge titanium is: Fe: 0.013wt%, O: 0.031wt%; the Brinell hardness HBW of the sponge titanium is 90N / mm 2 ;

[0080] S1-2. The sponge titanium obtained in step S1-1 is smelted twice in a vacuum consumable electric arc furnace to obtain a pure titanium ingot; wherein, the mass percentage composition of each element in the pure titanium ingot is: Fe: 0.02wt% , C: 0.016wt%, N: 0.018wt%, H: 0.004wt%, O: 0.042wt%, and the balance is Ti;

[0081] S2, slab forging:

[0082] The pure titanium ingot obtained in step S1-2 is heated to 1000° C., and then forged after being kept for 5 hours. Then, the surface forging defects and oxide scale of the pure titanium ingot after forging are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com