Negative plate, preparation method thereof and battery

A technology of negative electrode sheet and negative electrode, which is applied in the field of negative electrode sheet and its preparation, can solve problems affecting the electrochemical performance of batteries, and achieve the effects of accelerating transmission speed, increasing liquid retention, and improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

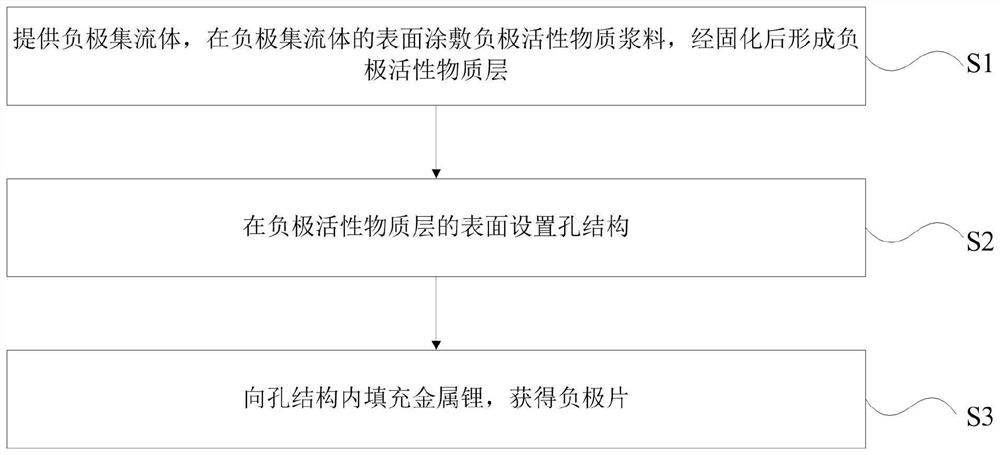

[0044] figure 2 It is a process flow diagram of preparing a negative electrode sheet in the embodiment of the present invention, combined with figure 2 As shown, the preparation method of the negative electrode sheet comprises the following steps:

[0045] Step S1, providing a negative electrode current collector 1, coating a negative electrode active material slurry on the surface of the negative electrode current collector 1, and forming a negative electrode active material layer 2 after curing;

[0046] Step S2, setting a hole structure 3 on the surface of the negative electrode active material layer 2;

[0047] Step S3, filling the hole structure 3 with metallic lithium to obtain a negative electrode sheet.

[0048] In the preparation method of the negative electrode sheet provided in the embodiments of the present application, a pore structure is arranged in the negative electrode active material layer, and metal lithium is embedded in the inside of the pore structure...

Embodiment 1

[0061] This embodiment provides a lithium-ion battery, including:

[0062] Preparation of negative electrode sheet: the negative electrode active material graphite Gr+20% SiO, binder PVDF and conductive carbon black are mixed, and a uniformly dispersed solid component is obtained by high-speed stirring, wherein the mass percentage of graphite Gr+20% SiO is 95wt% , the mass percentage of the binder PVDF is 2 wt %, and the mass percentage of the conductive carbon black is 3 wt %; the solid component and water are mixed uniformly to prepare the negative electrode active slurry, and the solid content of the negative electrode active slurry is 60 wt %. Provide copper foil as the negative electrode current collector, apply the negative electrode active slurry evenly on both sides of the copper foil, and the thickness of the negative electrode active material layer on one side surface of the negative electrode current collector is 100 μm, after drying, the negative electrode active ma...

Embodiment 2

[0067] This embodiment provides a lithium ion battery, and the preparation process of the lithium ion battery is the same as that of the embodiment 1, except that:

[0068] When preparing the negative electrode sheet, the surface of the negative electrode active material layer is punched by machining to form multiple pore structures, the pore density of the negative electrode active material layer is 30%, the diameter of each pore structure is 500 μm, and the depth Both are 30 μm. The square flexible packaging battery assembled in this example is denoted as C2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com