Load scheduling distribution method and platform for multi-furnace multi-machine complex production system

A production system and load scheduling technology, applied in the direction of complex mathematical operations, genetic rules, computer-aided design, etc., to achieve the effects of reducing frequent load changes, maximizing production profits, and minimizing energy consumption of equipment in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

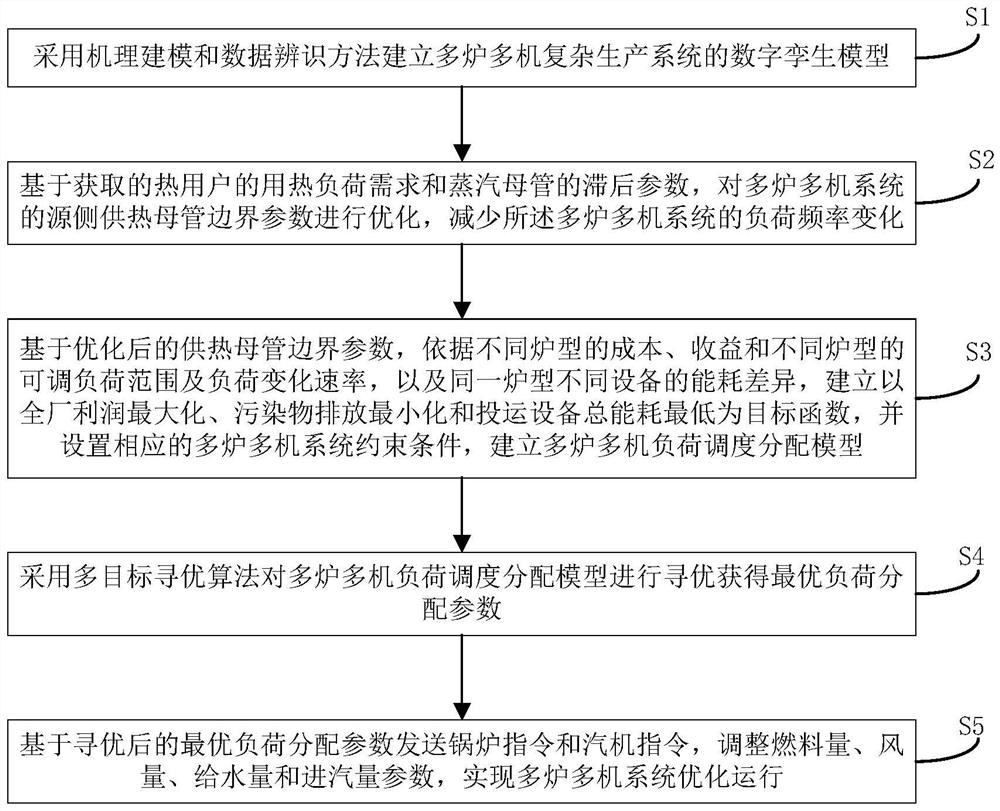

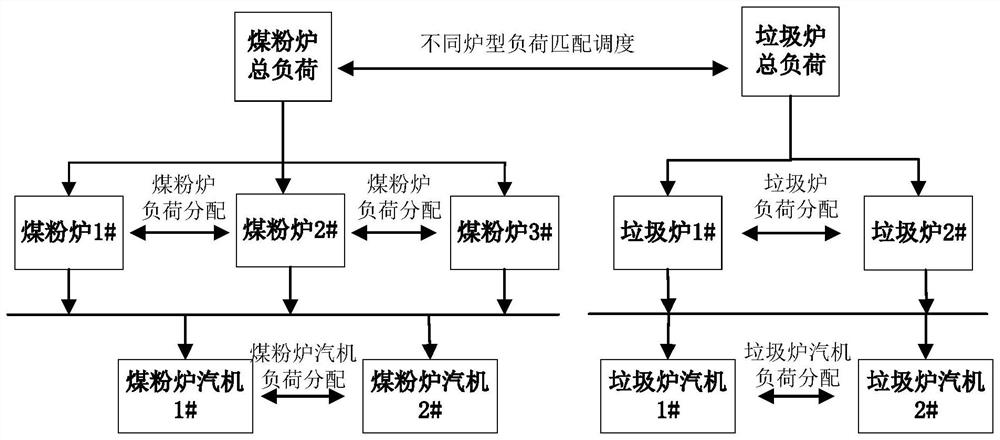

[0153] figure 1 It is a flow chart of the load scheduling and distribution method of the multi-furnace and multi-machine complex production system involved in the present invention.

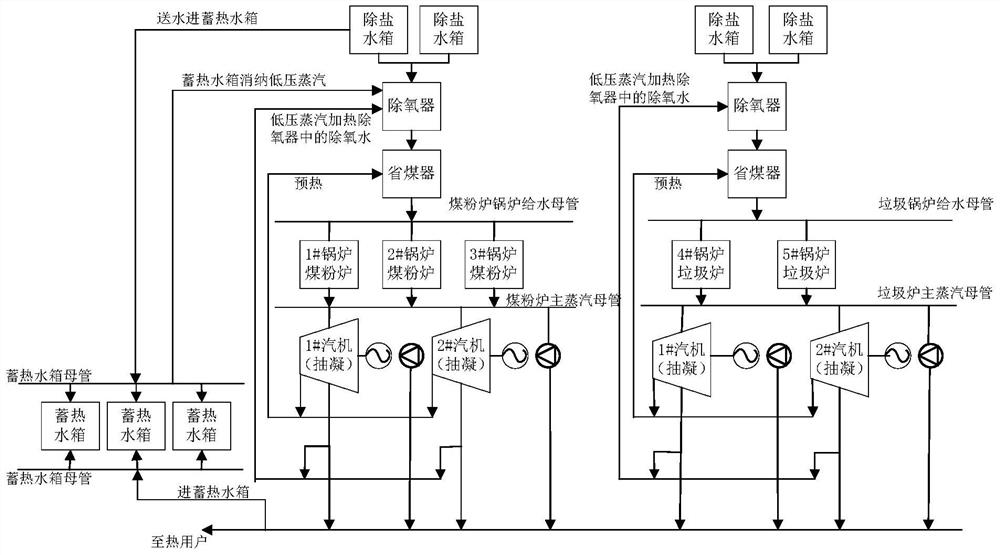

[0154] figure 2 It is a schematic diagram of the multi-furnace and multi-machine complex production system involved in the present invention.

[0155] like figure 1 , 2 As shown, the present embodiment 1 provides a load scheduling and distribution method for a multi-furnace and multi-machine complex production system, which includes:

[0156] Step S1, using mechanism modeling and data identification methods to establish a digital twin model of a multi-furnace multi-machine complex production system;

[0157] Step S2, based on the obtained heat load demand of the heat user and the lag parameter of the steam main pipe, optimize the boundary parameters of the source side heating main pipe of the multi-boiler and multi-machine system, so as to reduce the load frequency of the multi-boiler and mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com