Cargo transfer transport vehicle based on tray placement

A technology for transporting vehicles and goods, which is applied to vehicles used for freight, transportation and packaging, and motor vehicles. It can solve the problems of heavy workload, large site space occupied by tracks, and increased safety hazards in workshop transportation, so as to speed up work. The process, the maximization of production benefits, and the effect of forking objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

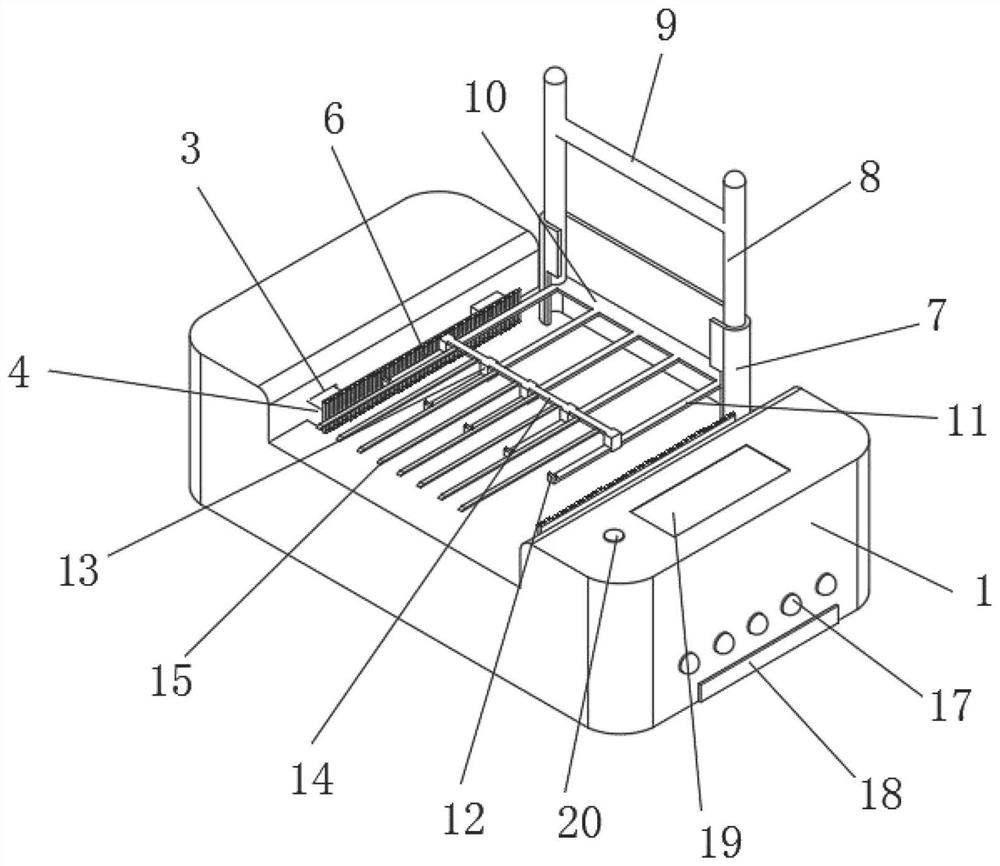

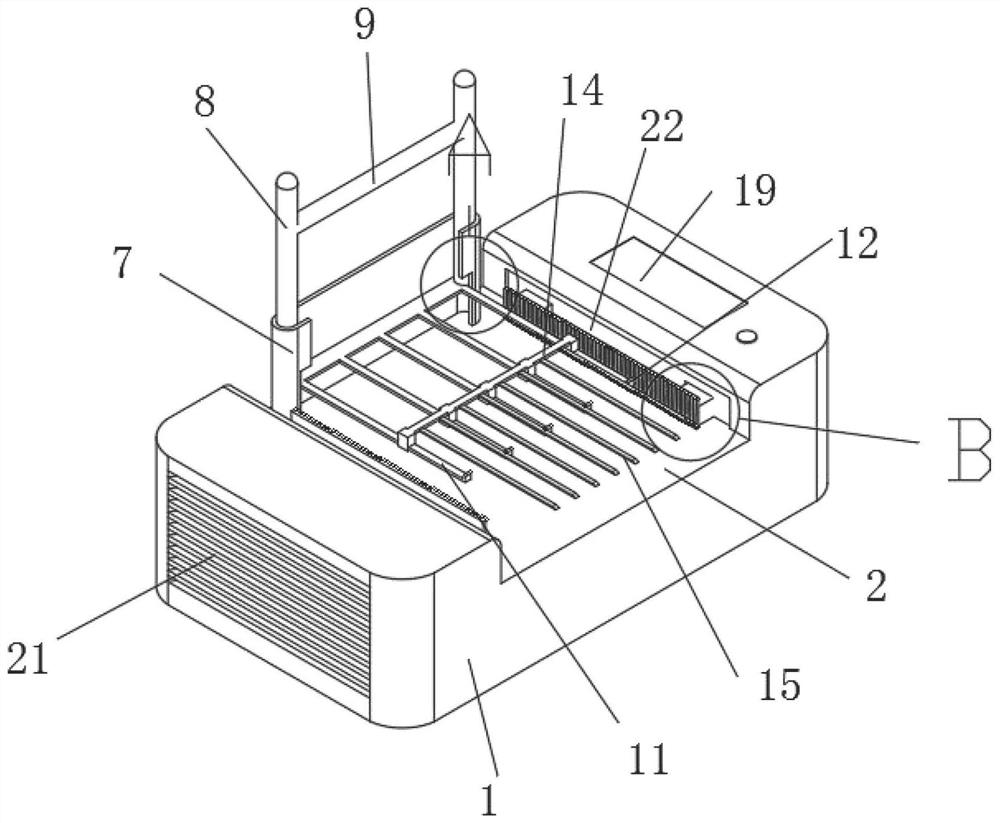

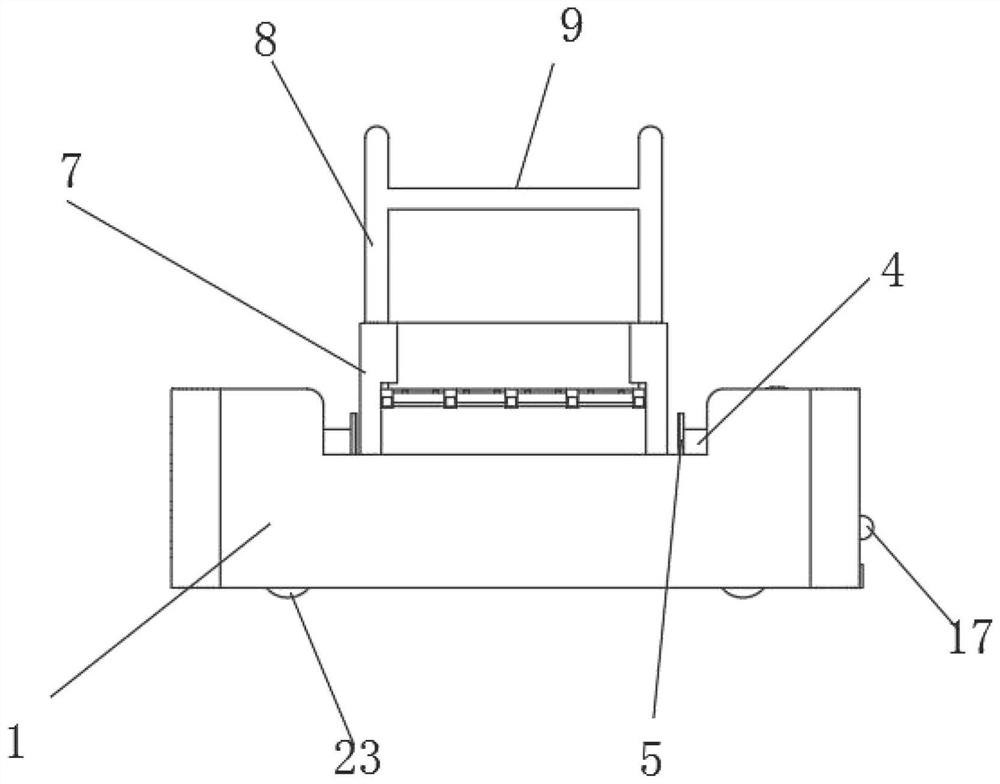

[0024] Example: see Figure 1-5 , the present invention provides a technical solution: a pallet-based cargo transfer transport vehicle, including a transport vehicle body 1, a receiving groove 2 is opened in the middle of the top of the transport vehicle main body 1, and a receiving groove 2 is provided on both sides of the inner wall of the receiving groove 2. Slot 3, the inner cavity of the retractable slot 3 is movably connected with a telescopic rod 4, the opposite side of the telescopic rod 4 is fixedly connected with an extrusion plate 5, and the opposite side of the extrusion plate 5 is fixedly connected with an anti-slip tooth 6, the design of the anti-slip tooth 6 The object can be locked when carrying the object. Compared with the traditional method of only using the extrusion plate 5 to compress it, it is more stable. The right side of the bottom of the receiving groove 2 is fixedly connected with a bracket 7, and the inner cavity of the bracket 7 is movably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com