Pressure vessel and method for manufacturing the same

A pressure vessel and ring-shaped technology, which is applied in the field of pressure vessels and its manufacturing, can solve the problems of reduced usage, difficulty in ensuring the structural rigidity of pressure vessels, and insufficient research results, and achieve the effect of reducing structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

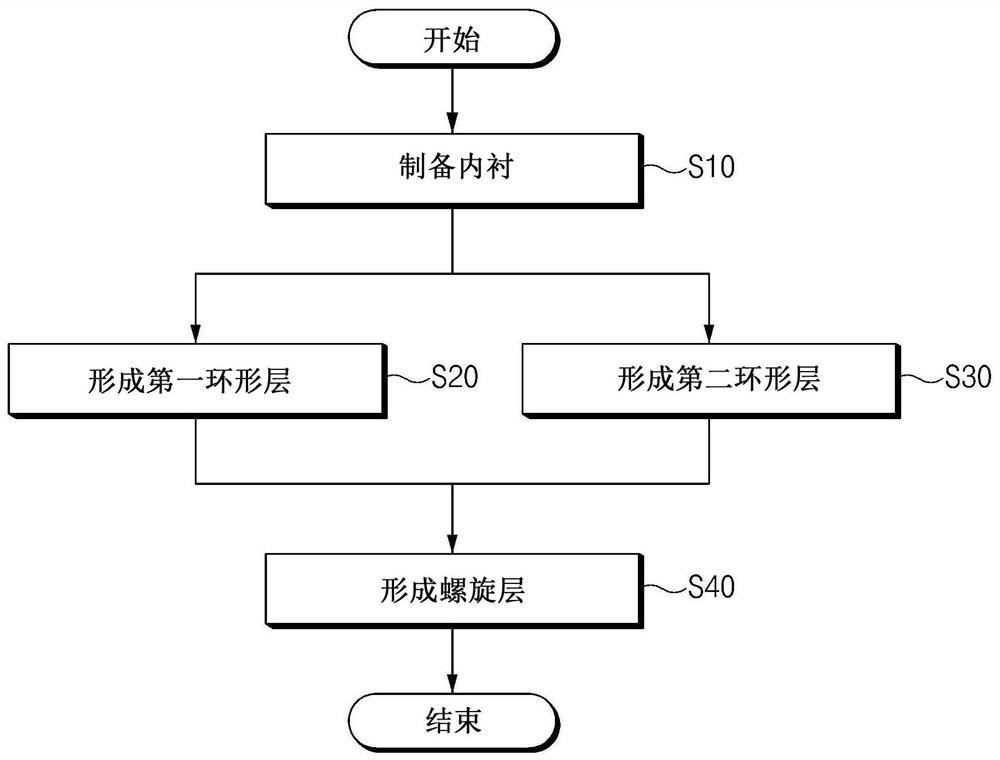

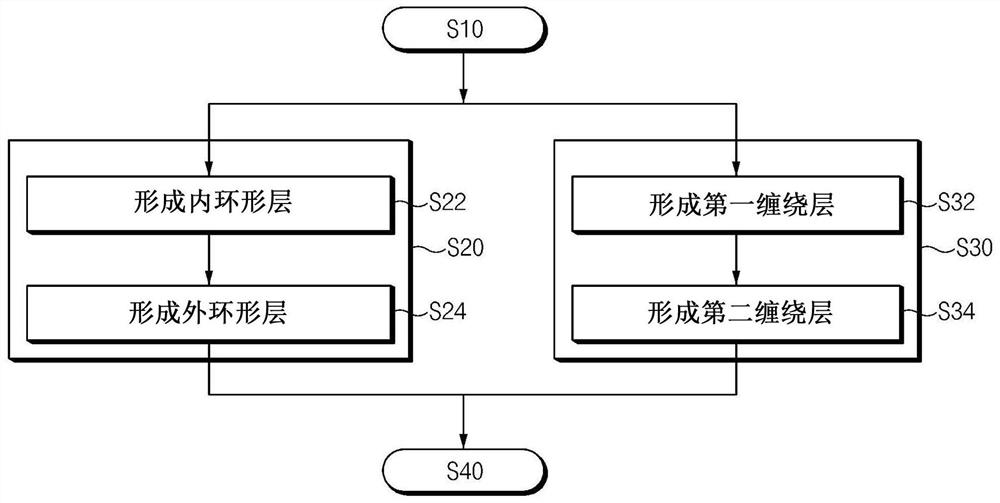

Method used

Image

Examples

Embodiment approach

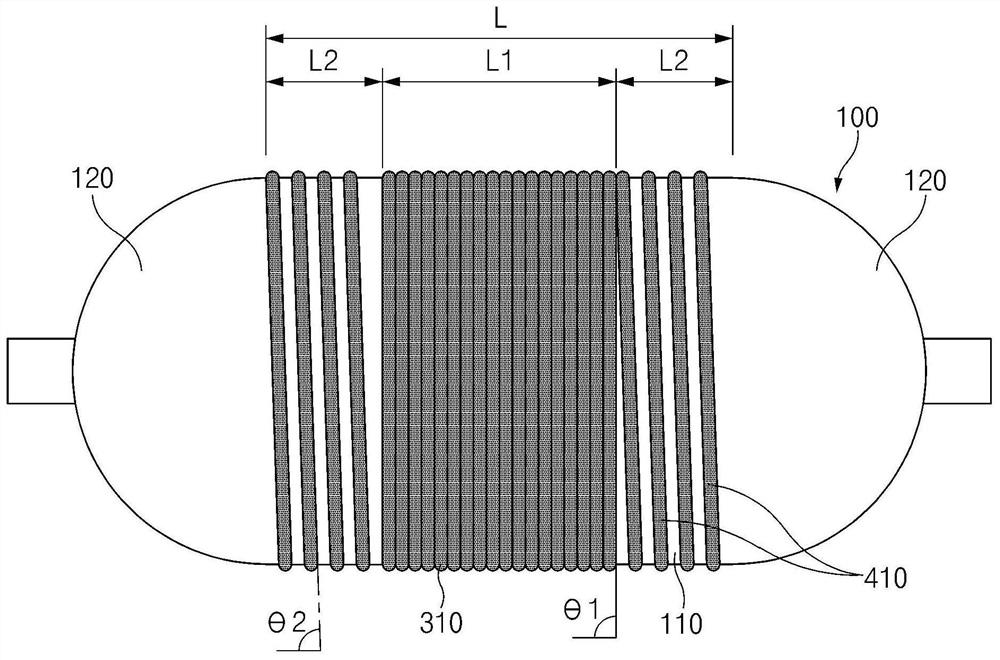

[0162] In the exemplary embodiments of the present disclosure described and illustrated above, an example has been described in which the pressure vessel includes a single carbon fiber layer including a first annular layer, a second annular layer, and a helical layer. However, according to another exemplary embodiment of the present disclosure, the pressure vessel may include a plurality of carbon fiber layers.

[0163] For example, refer to Figure 13 , the pressure vessel 10 includes an inner liner 100 and a carbon fiber layer 200, the inner liner includes a cylindrical portion 110 and a dome-shaped side portion 120, the side portions are provided at both ends of the cylindrical portion 110, and the carbon fiber layer includes: a first annular The layer 300 is arranged to surround a part of the outer peripheral surface of the cylindrical portion 110; the second annular layer 400 is arranged to surround the other portion of the outer peripheral surface of the cylindrical port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com