Slag type optimizing agent in copper smelting process and preparation method of slag type optimizing agent

An optimization agent, copper smelting technology, applied in the direction of improving process efficiency, etc., can solve the problem of no successful application cases for reference, so as to achieve good fluidity of slag, strong adsorption and inclusion capacity, and reduce treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

Embodiment 1

[0016] The obtained mixed raw material is a slag-type optimizer with a particle size of 0-5mm, which is bagged, sealed and stored in the warehouse for future use.

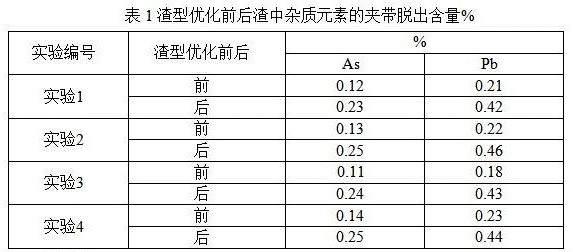

[0017] The slag type optimizer prepared in this example was used in copper pyrometallurgy, and the entrained removal content of impurity elements in the slag before and after the slag type optimization was compared, as shown in Table 1.

Embodiment 2

[0018] The obtained mixed raw material is a slag-type optimizer with a particle size of 0-5mm, which is bagged, sealed and stored in the warehouse for future use.

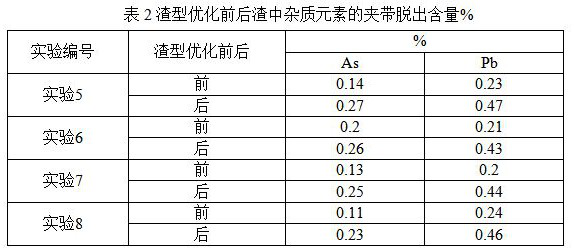

[0019] The slag type optimizer prepared in this example was used in copper pyrometallurgy, and the entrained removal content of impurity elements in the slag before and after the slag type optimization was compared, as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com