Clamping and feeding device for copper pipes

A technology of copper tubes and carts, applied in the directions of transportation and packaging, improvement of process efficiency, mechanical conveyors, etc., can solve the problems of copper coil defects and copper coil surface bumps, etc., to increase the area, avoid collision, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

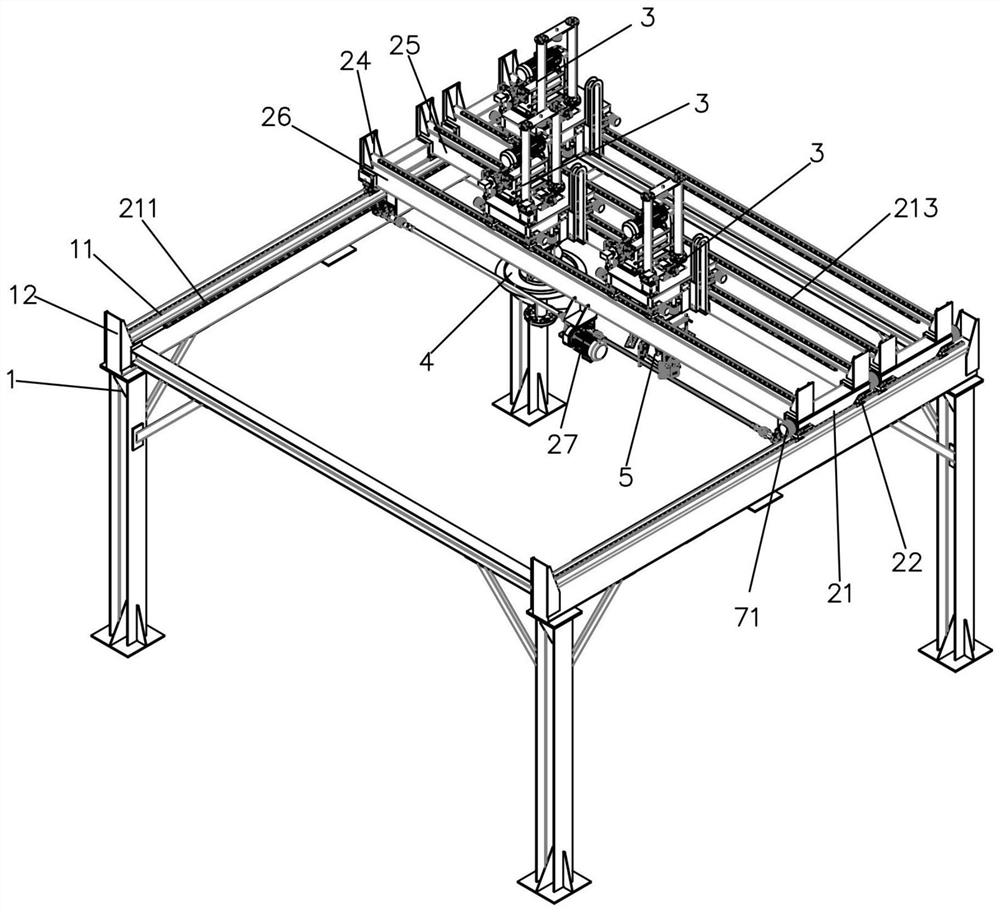

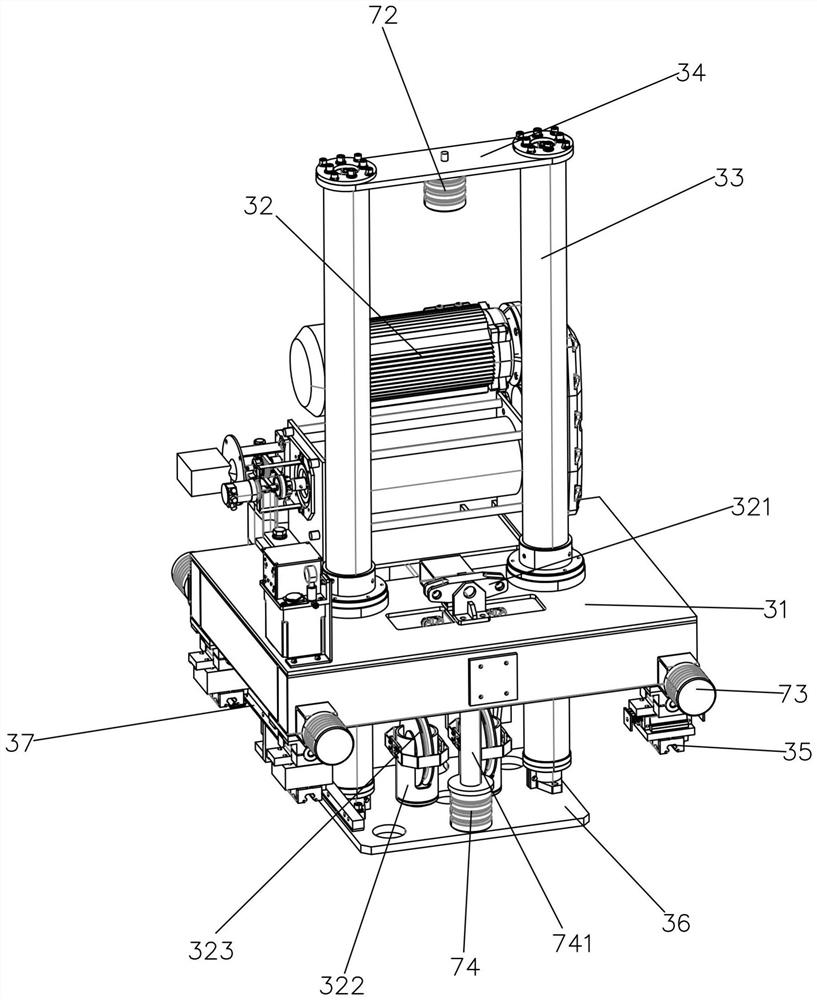

[0034] Example: a clamping and feeding device for copper pipes, such as Figure 1-Figure 12 As shown, it includes a frame 1, first guide rails 11 are provided on both sides of the top of the frame 1, and two sets of large vehicles are installed on the top of the frame 1 and the first guide rails 11. 1. Both ends are provided with a first side stop 12, and lifts 3 are slidably arranged on the top of the large-scale traveling vehicle. Below each lift 3 are correspondingly provided with a mosquito coil steel pipe coil hanger 4, an axis steel pipe coil hanger 5 and a large loose disk. The steel pipe spreader, the large-scale crane includes the first cart beam 25, the second cart beam 26, the cart cross frame 21, the first guide rail 11 slider, the cart traveling power motor 27, the first fixed frame 28, the second fixed frame The frame 212, the second guide rail 213 and the first rack 211, the horizontal frame 21 of the cart is arranged on the left and right sides of the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com