Bridge transport vehicle

A technology for transport vehicles and bridges, applied in the direction of transporting objects, transporting and packaging, and vehicles for freight, etc., can solve problems such as wing plate fracture, prefabricated beam instability, overturning, etc., to ensure stability, ensure consistency and The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments.

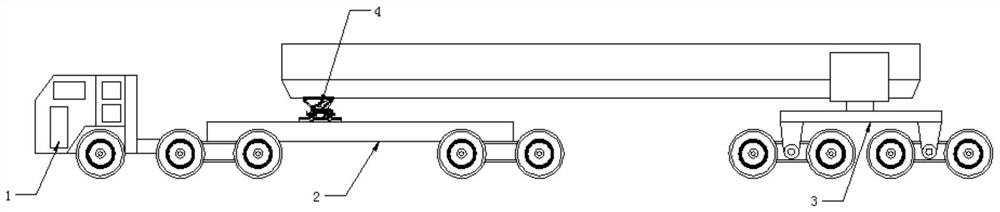

[0020] refer to figure 1 , a bridge transport vehicle, including a tractor 1, a semi-trailer 2 and a fast gun vehicle 3, the semi-trailer 2 is installed on the tractor 1, and a moving turntable 4 is arranged on the semi-trailer 2.

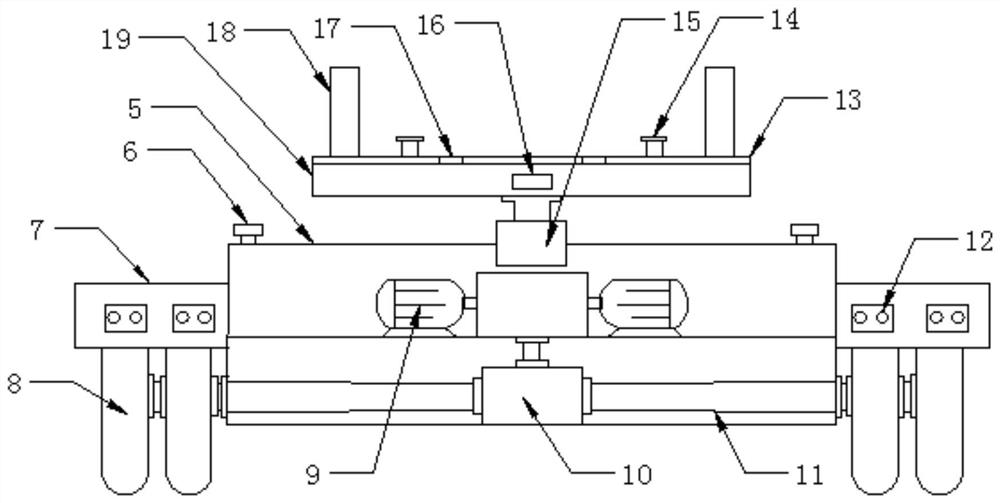

[0021] refer to figure 2 , the fast gun car 3 includes a transport body 5, a slide rail 13 and a gravity detection device 17, a rotatable hydraulic expansion device 15 is arranged above the transport body 5, and a bridge is arranged above the rotatable hydraulic expansion device 15 The bearing base 19 is provided with a balance detection device 16 inside the bridge bearing base 19 , the slide rail 13 is installed above the inside of the bridge bearing base 19 , and the gravity detection device 17 is installed inside the slide rail 13 . Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com