Valve control type ink and inkstone box

A technology of ink and inkstone, which is applied in the field of valve-controlled ink inkstone box, which can solve the problems of cumbersome and inconvenient carrying and use, and reduce the volume of the writing case, and achieve the effect of reducing the volume of the writing case, preventing ink from spilling, and being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

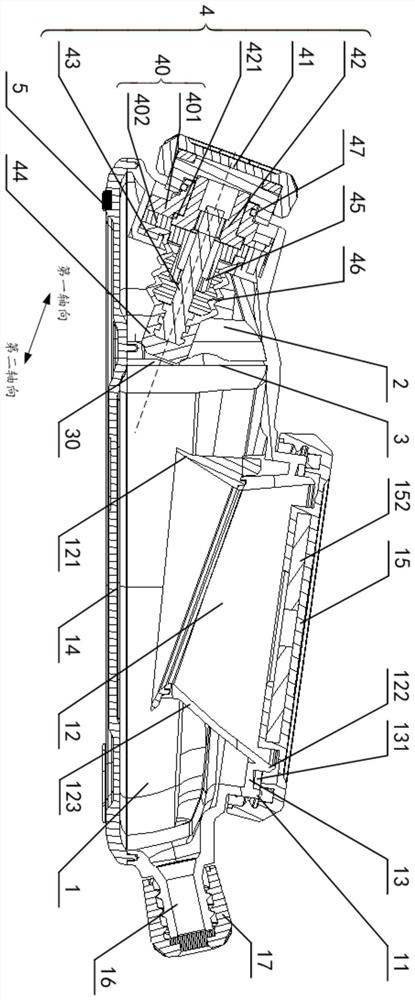

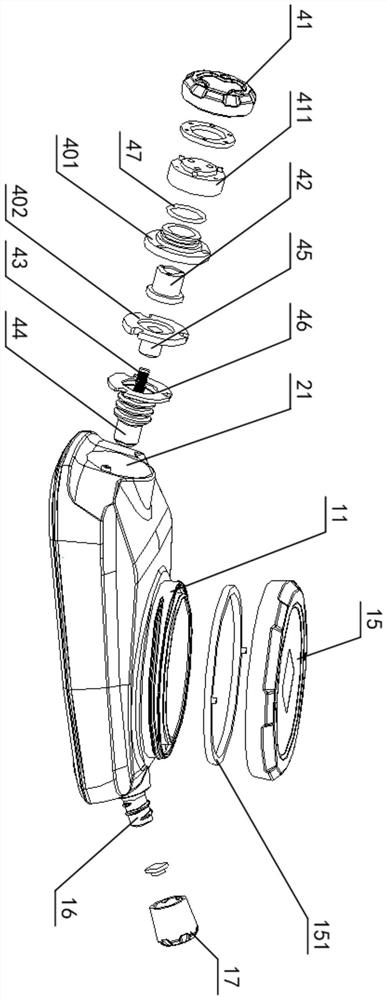

[0044] like Figures 1 to 3 As shown, the valve-controlled ink cartridge provided in this embodiment includes an ink-dipping chamber 1, an ink-storing chamber 2, a partition 3 and a rotary valve 4, wherein the ink-dipping chamber 1 It is the main body of the box. The ink storage chamber 2 and the ink storage chamber 1 are arranged side by side and are integrally formed. The partition 3 is used to separate the ink storage chamber 1 and the ink storage chamber. 2; the partition 3 is provided with a through hole 30 for connecting the ink dipping cavity 1 and the ink storage cavity 2, and the rotary valve member 4 is embedded in the ink storage cavity The outer sidewall of the ink storage chamber 2 is used to conduct or close the through hole 30 under the rotating operation, wherein the outer sidewall of the ink storage chamber 2 refers to the side away from the ink chamber 1 wall.

[0045] like Figures 1 to 3 As shown, in the specific structure of the valve-controlled ink ink...

Embodiment 2

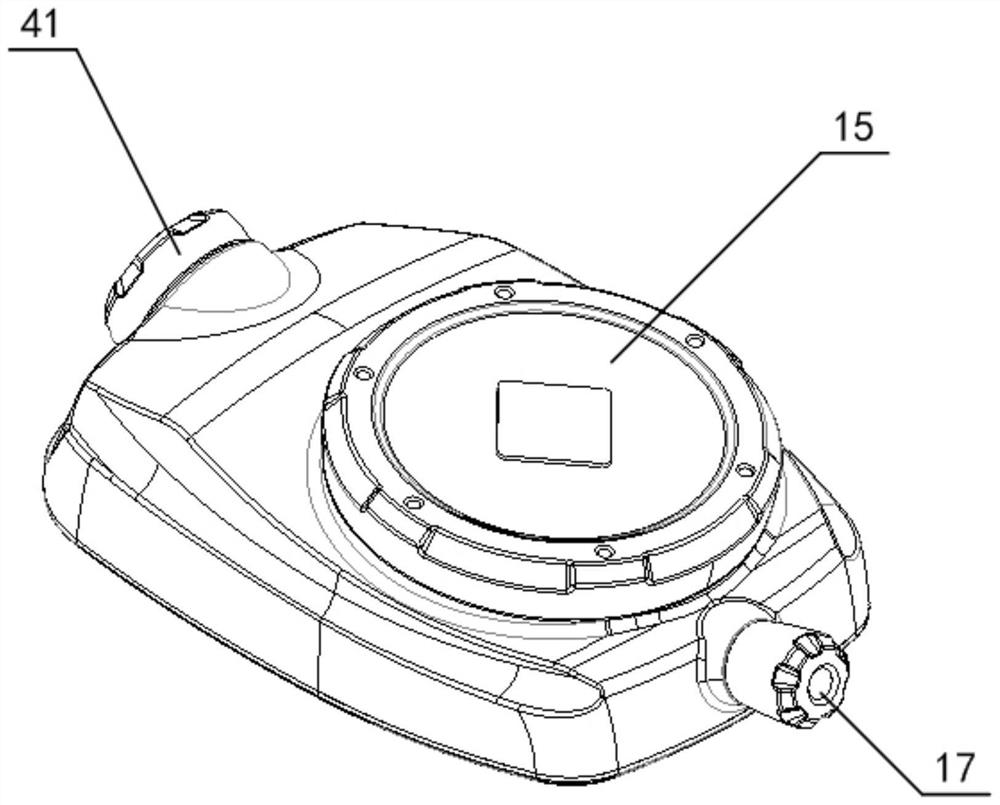

[0071] like Figure 4As shown in the figure, based on the technical solution of the first embodiment, the present embodiment also provides an ink cartridge with an anti-stick cover, which is different from the valve-controlled ink cartridge described in the first embodiment in that although there is no storage The design of the ink chamber 2, the separator 3 and the rotary valve 4, etc., can also realize convenient ink dipping, licking and scraping ink, convenient recovery of residual ink, sealing against dry ink, no cleaning and anti-splashing. The effect is good and other advantages, but also has a strong practicality.

[0072] The technical effect of the anti-stick cover type inkstone box provided in this embodiment can be directly derived with reference to the technical effect of the first embodiment, and will not be repeated here.

Embodiment 3

[0074] like Figure 5 As shown, this embodiment also provides another anti-stick cover type inkstone box based on the technical solution of the second embodiment, which is different from the anti-stick cover type inkstone box described in the second embodiment in that: although the The top surface and the bottom surface of the ink dipping chamber 1 are arranged in parallel, but the ink dipping hole 12 can also be inclined correspondingly, so as to optimize the angle of using the brush when dipping ink, so as to achieve the purpose of convenient ink dipping.

[0075] The technical effect of the anti-stick cover type inkstone box provided in this embodiment can be directly derived with reference to the technical effect of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com