Molding method of pulse current curing carbon fiber composite material

A composite material and molding method technology, applied in the direction of weight reduction, etc., can solve the problems of carbon fiber perforation, affecting the overall mechanical properties of carbon fiber composite components, and excessive current, and achieve the effect of short curing cycle, high curing efficiency and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

Specific implementation one:

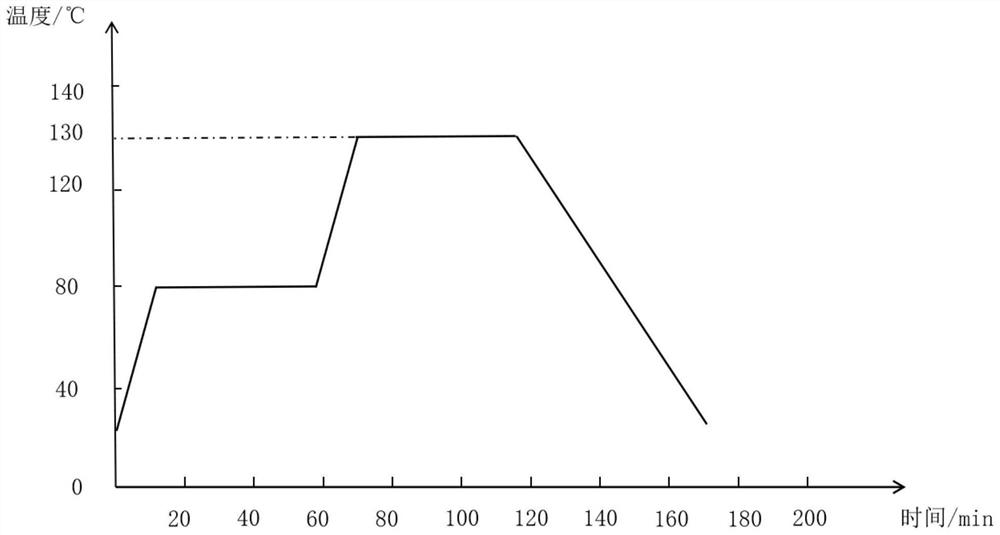

[0072] The carbon fiber prepreg used in this example is a unidirectional T700 carbon fiber / epoxy resin prepreg. The material size is 240mm long*100mm*0.125mm*8 layers, and the volume fraction of carbon fiber is 0.65. The curing temperature process of the composite material It is required to keep at 80℃ for 40min and at 130℃ for 40min.

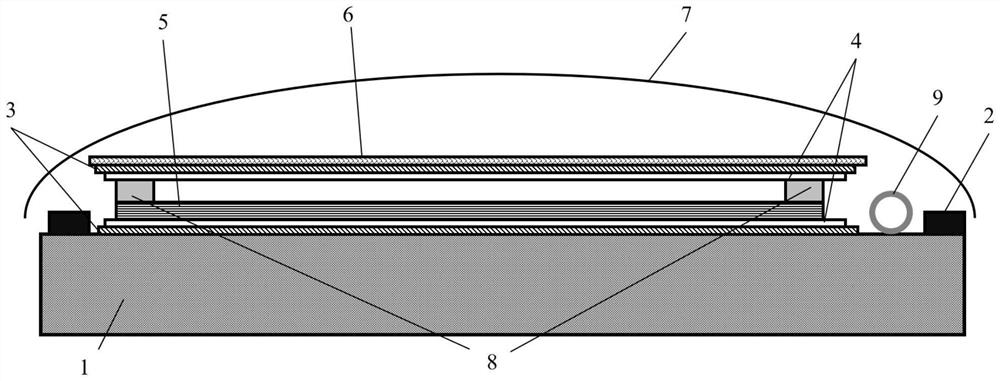

[0073] The rigid mold selected is a 1060 aluminum plate with a length of 300mm, a width of 200mm and a thickness of 2mm. The insulating film is a Teflon film with a length of 260mm, a width of 150mm and a thickness of 1mm. The heat resistance limit is 260°C. It is a high-strength polyester fiber cloth with a length of 250mm, a width of 150mm and a thickness of 1mm, with a heat resistance limit of 150℃. 10mm thick, 3mm long and 120mm long copper strip, the wire adopts national standard soft wire copper wire, and the cross-sectional area is 70mm 2 .

[0074] Specific steps are as follows:

[0075] Step 1: Materia...

specific Embodiment approach 2

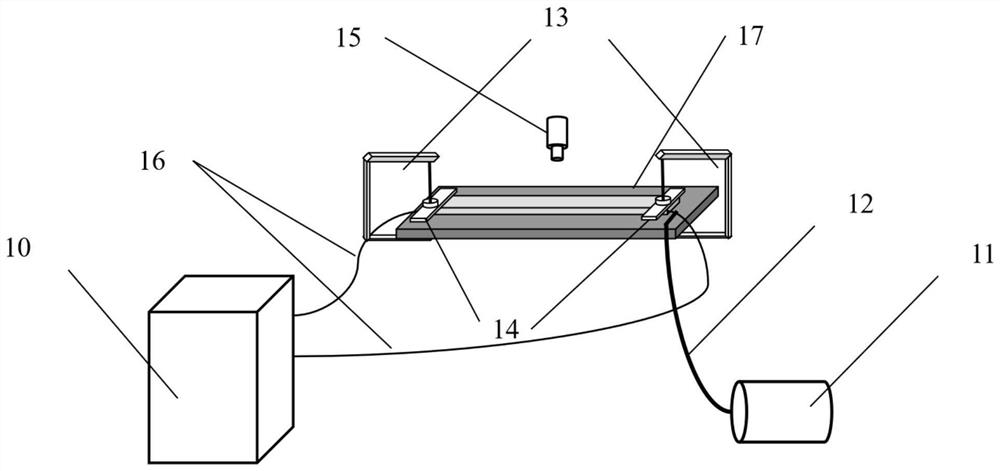

[0088] The high-frequency pulse power supply described in this embodiment can provide 0-10000A pulse current, the output frequency is adjustable from 0-200KHz, the output duty cycle is adjustable from 0-100%, and the pulse form is adjustable in one-way pulse or two-way pulse.

Specific implementation two:

[0090] The carbon fiber prepreg 5 used in this example is a bidirectional T300 carbon fiber / epoxy resin prepreg. The material size is 200mm long*150mm*0.25mm*8 layers, and the carbon fiber volume fraction is 0.68. The carbon fiber prepreg 5 has a The curing temperature process requires holding at 180°C for 150min. The rigid mold selected is tempered glass with a length of 400mm, width of 300mm and a thickness of 5mm. Because the surface of the tempered glass is insulated, no insulating cloth is required. The air felt is a non-woven fabric of high temperature resistant polyester fiber material with a length of 250mm, a width of 200mm and a thickness of 1mm. The heat resista...

specific Embodiment approach 3

[0104] The temperature probe described in this embodiment is an infrared imaging thermometer, and the temperature measurement range is 0-400°C. The temperature distribution of the carbon fiber prepreg can be observed in the global range at the height placed.

[0105] The high-frequency pulse power supply described in this embodiment can provide 0-10000A pulse current, the output frequency is adjustable from 0-300KHz, the output duty cycle is adjustable from 0-100%, and the pulse form is adjustable in one-way pulse or two-way pulse.

Specific implementation three:

[0107] The carbon fiber prepreg used in this example is a unidirectional T300 carbon fiber / polypropylene prepreg, and the material size is 350mm long*300mm*0.25mm*8 layers, wherein the carbon fiber volume fraction is 0.60, and the curing temperature of the carbon fiber prepreg The process requires holding at 150°C for 30min. The rigid mold selected is a quartz plate with a length of 400mm, a width of 400mm and a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com