Flexible calcium lanthanum chromate/silicon oxide composite fiber material with high infrared emissivity as well as preparation method and application of flexible calcium lanthanum chromate/silicon oxide composite fiber material

An infrared emissivity and composite fiber technology, which is applied in the field of high infrared emissivity flexible calcium lanthanum chromate/silicon oxide composite fiber material and its preparation, can solve the problem that infrared radiation nanomaterials cannot be used alone, the preparation method is complicated, and it is difficult to recycle, etc. problems, to achieve the effect of reducing energy consumption, simple operation and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Dissolve tetraethyl orthosilicate in the mixed solvent of water and ethanol (the mass ratio of water and ethanol is 1:1), obtain solution A, the concentration of tetraethyl orthosilicate in solution A is 50wt%, stirring speed is 400rpm, the stirring temperature is 26°C, add phosphoric acid while stirring, the mass ratio of phosphoric acid to tetraethyl orthosilicate is 0.01:1. After stirring at room temperature for 8 hours, a uniform inorganic precursor solution A was obtained.

[0055] Add PVA (polyvinyl alcohol) to the inorganic precursor solution A prepared above to obtain solution B. The concentration of PVA in solution B is 1.5wt%, the stirring speed is 500rpm, and the stirring temperature is 80°C. After 3 hours of stirring, a uniform Silica spinning solution.

[0056] Dissolve chromium oxide, lanthanum oxide, and calcium oxide (the molar ratio of chromium oxide, lanthanum oxide, and calcium oxide is 1:0.9:0.1) into a mixed solvent of water, ethanol, and N,N-dimet...

Embodiment 2

[0062] Dissolve tetraethyl orthosilicate in the mixed solvent of water and ethanol (the mass ratio of water and ethanol is 1:1), obtain solution A, the concentration of tetraethyl orthosilicate in solution A is 65wt%, stirring speed is 400rpm, the stirring temperature is 26°C, add phosphoric acid while stirring, the mass ratio of phosphoric acid to tetraethyl orthosilicate is 0.01:1. After stirring at room temperature for 8 hours, a uniform inorganic precursor solution A was obtained.

[0063] Add PVA to the inorganic precursor solution A prepared above to obtain solution B. The concentration of PVA in solution B is 1.8wt%, the stirring speed is 500rpm, and the stirring temperature is 80°C. After 3h stirring, a uniform silica spinning solution.

[0064] Dissolve chromium oxide, lanthanum oxide, and calcium oxide (the molar ratio of chromium oxide, lanthanum oxide, and calcium oxide is 1:0.8:0.2) into a mixed solvent of water, ethanol, and N,N-dimethylformamide (water, The ma...

Embodiment 3

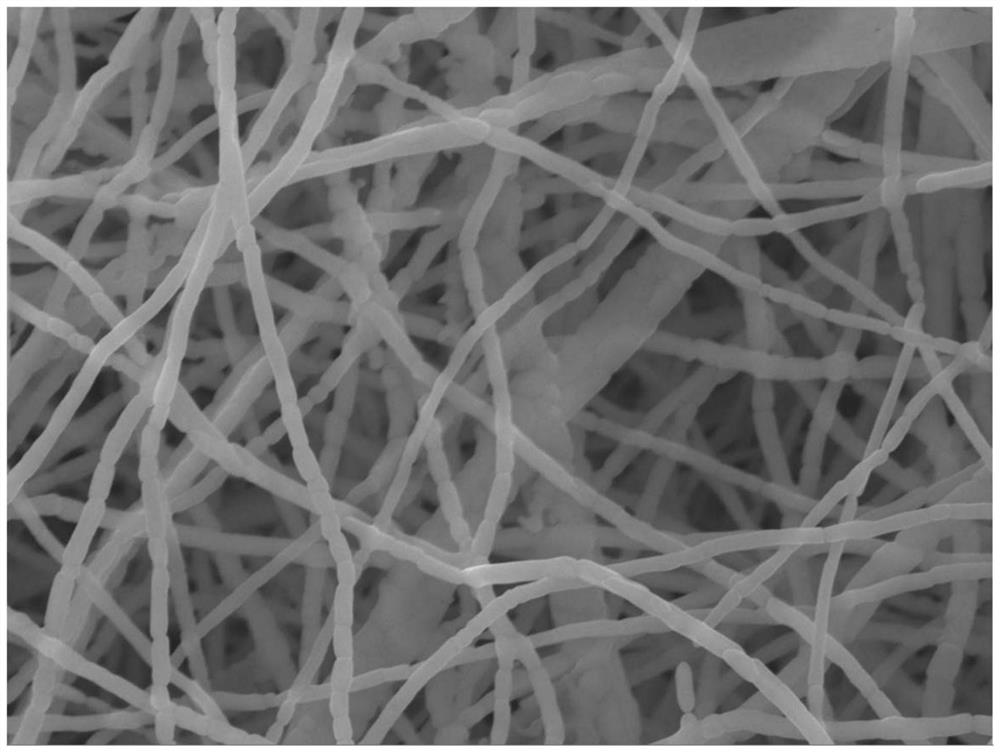

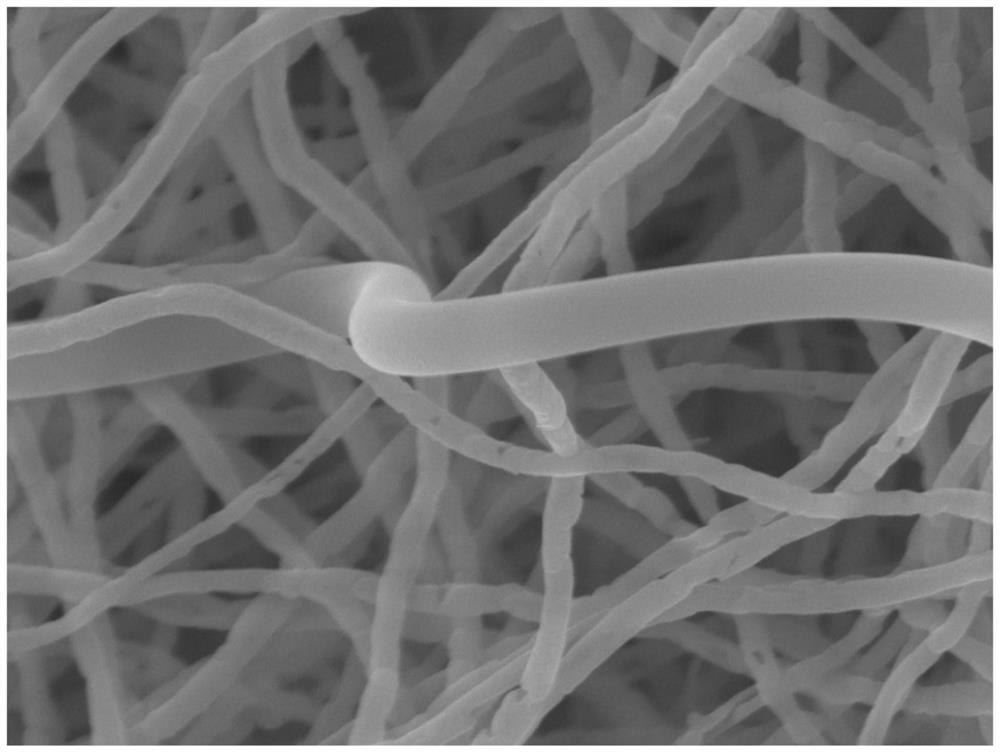

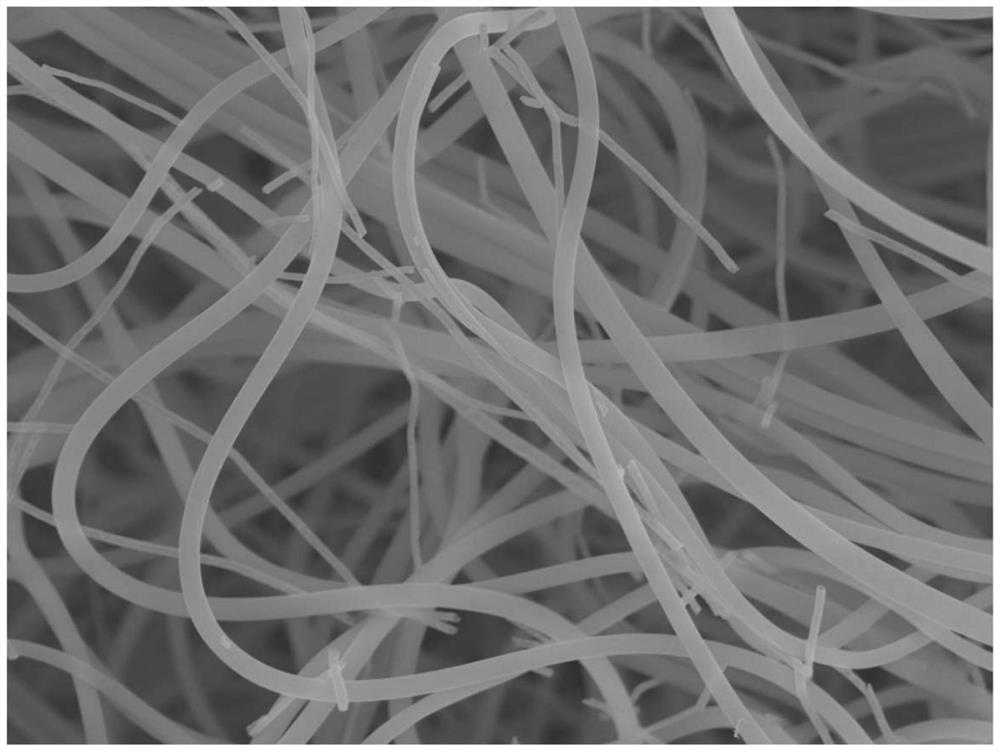

[0070] Compared with Example 2, most of them are the same, except that the volume ratio of silica spinning solution and calcium lanthanum chromate spinning solution is changed to 3:1. The obtained calcium lanthanum chromate / silica composite nanofibrous material such as image 3 As shown, the silica fiber and the calcium lanthanum chromate fiber are interpenetrated and distributed, the silica fiber is continuous, the surface is smooth and flat, and the calcium lanthanum chromate exists in the form of short fibers. The calcium lanthanum chromate fiber diameter in the material is 150nm, the silicon dioxide fiber diameter is 260nm, the fiber softness is 130mN, and the infrared emission rate is 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com