Pole piece structure for improving infiltration of lithium ion battery in thermal compounding process

A technology of lithium-ion batteries and heat recombination, which is applied in the direction of non-aqueous electrolyte battery electrodes, structural parts, secondary batteries, etc., can solve the problems of poor wetting effect of pole pieces, shortening the infiltration time of formation, etc., to shorten the infiltration time of formation, Facilitates wetting and enhances viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

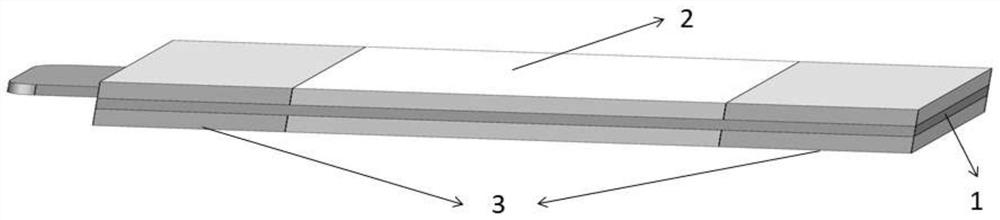

Embodiment 1

[0032] In the negative pole piece, the glue material is polyvinylidene fluoride, the thickness of the material area is 100μm, the width of the material area is 455mm, the thickness of the glue area at both ends is 105μm, and the width of the glue area is 25.5mm;

[0033] In the positive pole piece, the coating material is polyvinylidene fluoride, the thickness of the material area is 100 μm, the width of the material area is 450 mm, the thickness of the coating area at both ends is 105 μm, and the width of the coating area is 25 mm.

Embodiment 2

[0035] The width of the material area of the negative pole piece is 480mm, the width of the glue area at both ends is 13mm, the width of the material area of the positive pole piece is 475mm, and the width of the glue area at both ends is 12.5mm, and other conditions are the same as in Example 1.

Embodiment 3

[0037] The width of the material area of the negative pole piece is 404mm, the width of the glue area at both ends is 51mm, the width of the material area of the positive pole piece is 400mm, and the width of the glue area at both ends is 50mm, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com