Method for preparing MA3Bi2I9 perovskite solar cell by controlling BiI3 film orientation through solvent evaporation induction

A technology of evaporation induction and thin film orientation, which is applied in the field of solar cells, can solve the problems of grain crossing difference, achieve the effect of optimizing reaction time and facilitating carrier transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

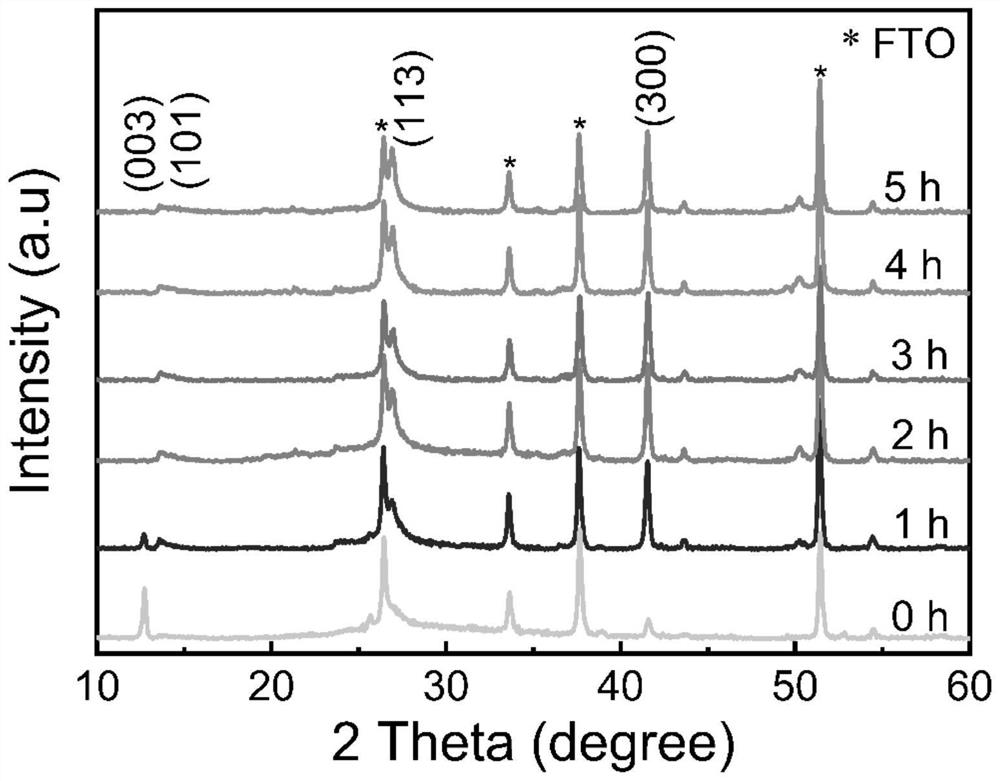

[0043] 1) BiI 3 Preparation of precursor solution: Weigh 1 mmol of bismuth iodide (BiI 3 ), dissolved in 1 mL of DMF, followed by stirring at room temperature for 12 hours to obtain a solution of 1 mmol / mL;

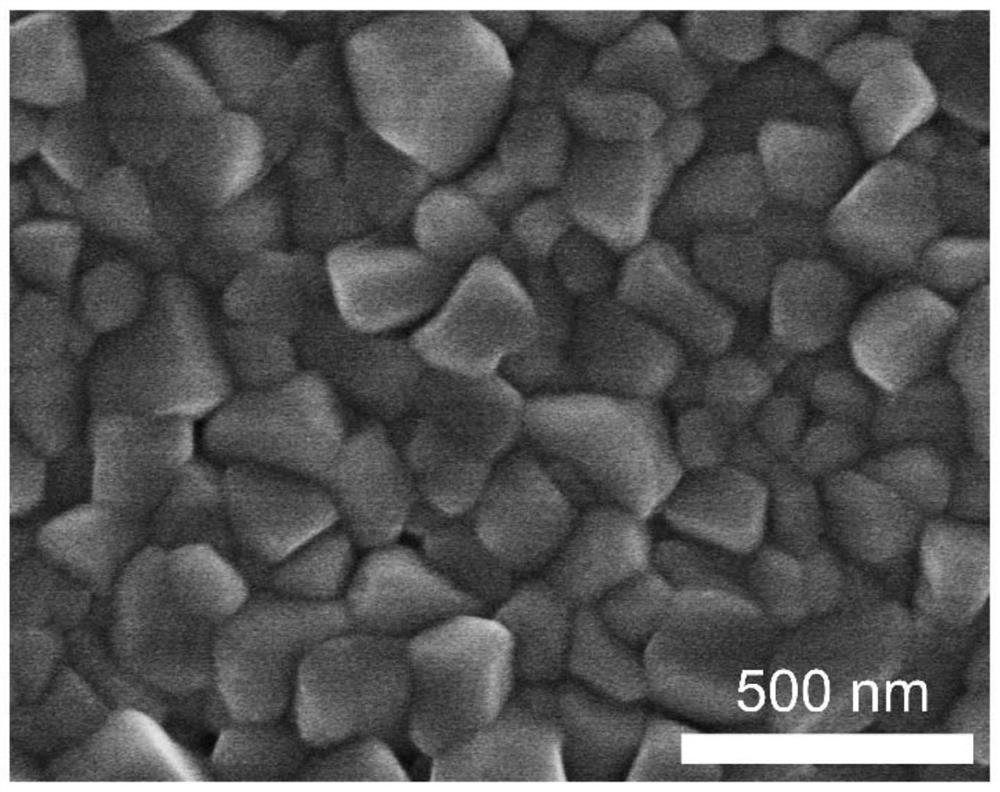

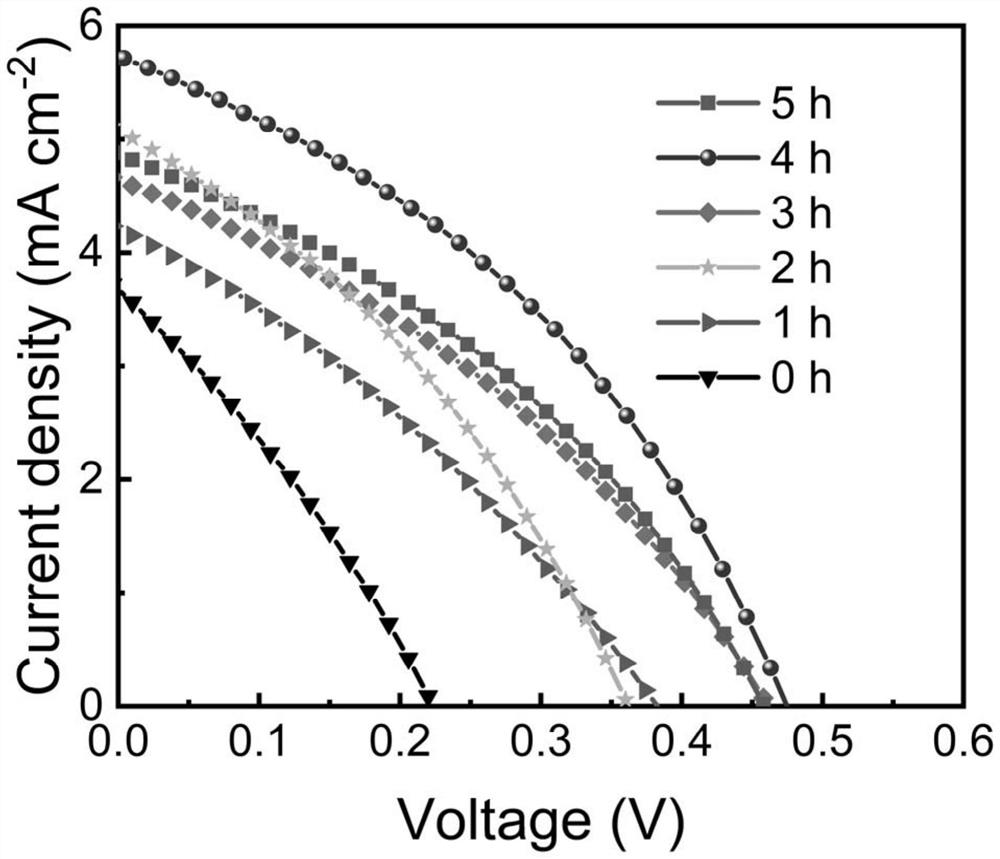

[0044] 2) BiI 3 Thin film pre-preparation: the precursor solution was covered with an electron transport layer on the FTO substrate, rotated at a speed of 3000rpm for 30s by a homogenizer, and then placed in an airtight container in a glove box to stand for 0h;

[0045] 3) BiI 3 Thin film annealing: BiI after standing 3 The film was put into a heating table at 120°C for 30min annealing treatment;

[0046] 4) BiI 3 Coexistence with MBI Thin Film Preparation: BiI After Annealing 3 The film was placed in a lidded glass petri dish and the MAI powder was evenly dispersed around it. The glass petri dish was placed in a vacuum drying oven, and MAI was deposited by heating at a low pressure of 10KPa at 100°C, and the reaction time was 30min;

[0047] 5) Preparation of hol...

Embodiment 2

[0051] 1) BiI 3 Preparation of precursor solution: Weigh 1 mmol of bismuth iodide (BiI 3 ), dissolved in 1 mL of DMF, followed by stirring at room temperature for 12 hours to obtain a solution of 1 mmol / mL;

[0052] 2) BiI 3 Thin film pre-preparation: the precursor solution is covered with an electron transport layer on the FTO substrate, rotated at a speed of 3000rpm for 30s by a glue homogenizer, and then placed in an airtight container to stand for 1h;

[0053] 3) BiI 3 Thin film annealing: BiI after standing 3 The film was put into a heating table at 120°C for 30min annealing treatment;

[0054] 4) BiI 3 Coexistence with MBI Thin Film Preparation: BiI After Annealing 3 The film was placed in a lidded glass petri dish and the MAI powder was evenly dispersed around it. The glass petri dish was placed in a vacuum oven, and MAI was deposited by heating at a low pressure of 10KPa at 100°C, and the reaction time was 30min;

[0055] 5) Preparation of hole transport layer:...

Embodiment 3

[0059] 1) BiI 3 Preparation of precursor solution: Weigh 1 mmol of bismuth iodide (BiI 3 ), dissolved in 1 mL of DMF, followed by stirring at room temperature for 12 hours to obtain a solution of 1 mmol / mL;

[0060] 2) BiI 3 Film pre-preparation: the precursor solution is covered with an electron transport layer on the FTO substrate, rotated at 3000rpm for 30s by a glue homogenizer, and then placed in a closed container for 2h;

[0061] 3) BiI 3 Thin film annealing: BiI after standing 3 The film was put into a heating table at 120°C for 30min annealing treatment;

[0062] 4) BiI 3 Coexistence with MBI Thin Film Preparation: BiI After Annealing 3 The film was placed in a lidded glass petri dish and the MAI powder was evenly dispersed around it. The glass petri dish was placed in a vacuum oven, and MAI was deposited by heating at a low pressure of 10KPa at 100°C, and the reaction time was 30min;

[0063] 5) Preparation of hole transport layer:

[0064] Preparation of sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com