Production equipment and method for batch casting and micro-dipping of ultrathin polymer composite film

A technology of production equipment and production method, which is applied in the field of casting micro-dip coating batch production equipment and method of ultra-thin film polymer composite film, can solve the problem that it cannot be used to prepare ultra-thin film polymer composite film, and achieves easy parameters. The effect of controlling, saving production costs and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

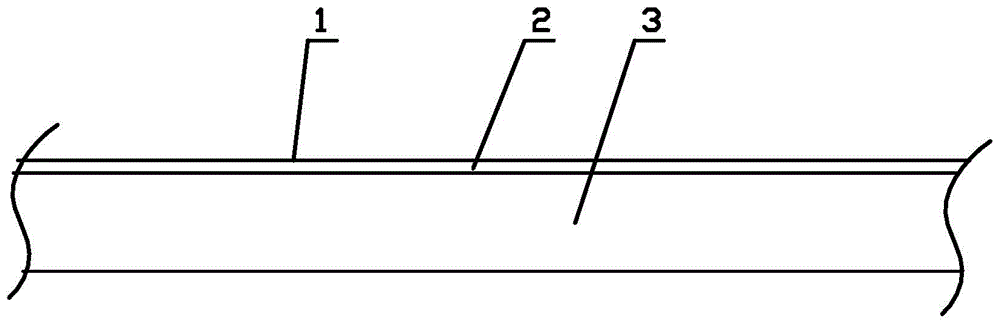

[0053] The present invention uses Teflon AF2400 as the material of the homogeneous non-porous polymer ultra-thin film layer 2, and Teflon AF2400 is a polymer with a high oxygen permeability or a high selectivity to oxygen permeation that obeys a dissolution-diffusion model. The highly asymmetric submicron polysulfone is used as the material of the porous ultra-thin film carrier layer 3 . The average pore size distribution characteristics of the highly asymmetric sub-micron polysulfone are as follows: 1. The highly asymmetric sub-micron polysulfone is used as a porous ultra-thin film carrier layer 3, which is the surface micro-dipped with Teflon AF2400 solution , that is, the surface in contact with the homogeneous non-porous polymer ultra-thin film layer 2, its average pore diameter is 0.05 micron, 2, the average pore diameter is 0.05 micron thickness is only 10 microns, 3, the average pore diameter of the outer surface is 5.0 Micron, 4. The total thickness is 120 microns, and...

Embodiment 2

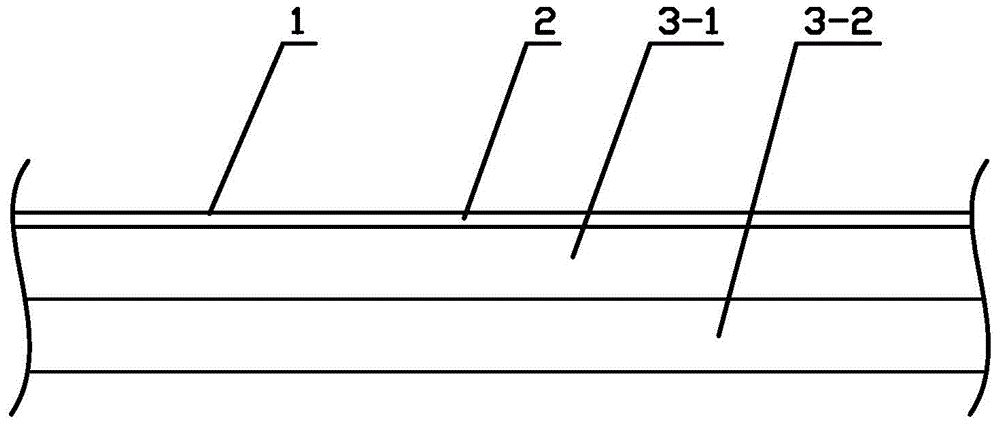

[0063] Present embodiment uses described Teflon AF2400 as the material of homogeneous non-porous polymer ultra-thin film layer 2, selects polytetrafluoroethylene porous polymer and polyester non-woven fabric as porous ultra-thin film carrier layer 3, as attached figure 2 As shown, the polytetrafluoroethylene porous polymer layer is the porous ultra-thin film carrier layer 3-1, and the polyester non-woven support substrate is the porous ultra-thin film carrier layer 3-2, the porous ultra-thin film carrier layer 3 -1 and the porous ultra-thin film carrier layer 3-2 are made into the porous ultra-thin film carrier layer 3 by lamination and bonding. The characteristics of using the porous ultra-thin film carrier layer 3-1 and the porous ultra-thin film carrier layer 3-2 as the carrier layer material are: 1. The average pore diameter of the polytetrafluoroethylene porous polymer is 0.02 micron and the thickness is 40-60 micron , the porosity is 60%; 2, the polyester non-woven supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com