Flow-controllable and temperature-controllable liquid evaporator

A liquid evaporation and evaporation machine technology, applied in the field of controllable flow and temperature control liquid evaporation machine, can solve the problems of large heat loss, large fluid resistance, large equipment volume, etc., to extend the service life, meet the needs of use, and the pipeline design is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

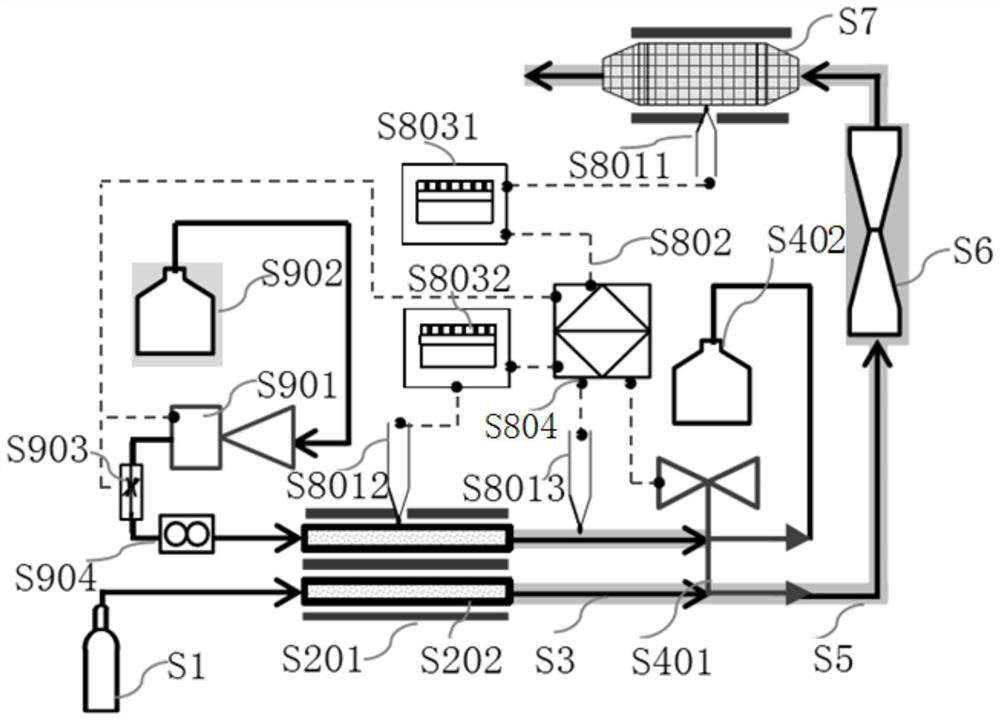

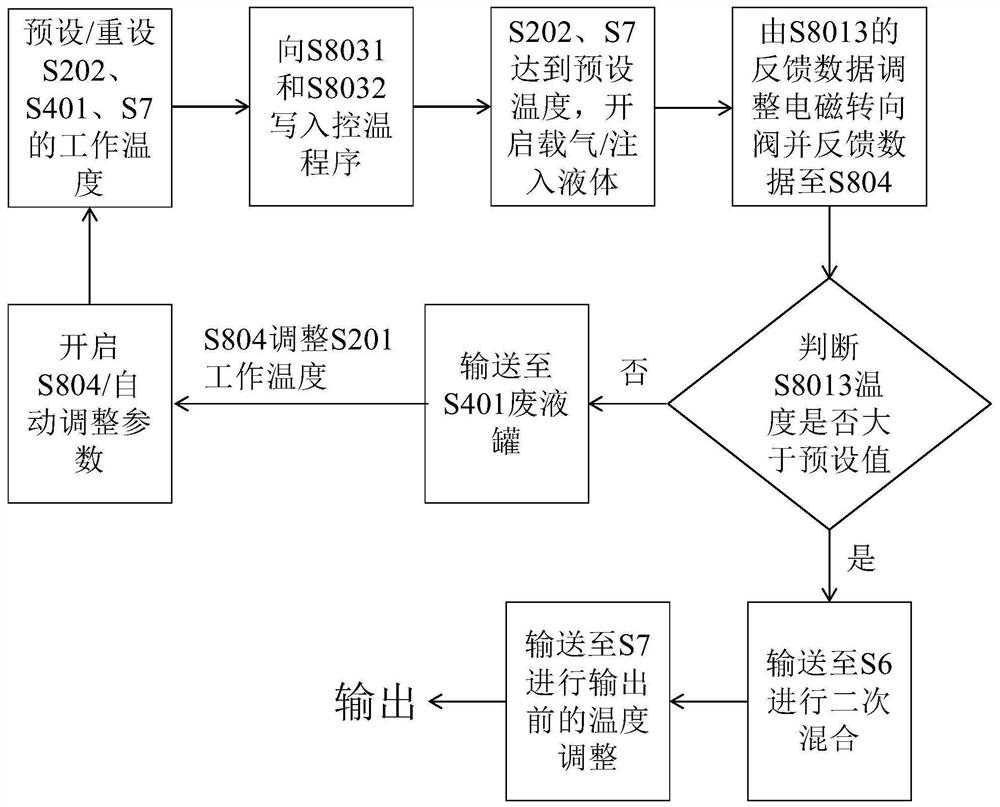

[0047] (1) Such as figure 1 As shown, the embodiment of the present invention provides a controllable flow temperature liquid evaporator, including: a carrier gas supply device S1, a constant temperature water storage chamber S902, and a logic control unit S804; a carrier gas supply device S1, a constant temperature water storage chamber S902 Are respectively connected to the gas pipeline S3 through the evaporator S202; a heating wire S201 is installed at the evaporator S202; a first dual platinum rhodium thermocouple S8011 is installed at the heat exchanger S7, and a second double thermocouple is installed at the evaporator S202. Platinum rhodium thermocouple S8012, valve group S401 and third dual platinum rhodium thermocouple S8013 are respectively arranged on gas pipeline S3; the first dual platinum rhodium thermocouple S8011 is connected to the first temperature controller S8031, the second dual platinum rhodium thermocouple Even S8012 is connected to the second temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com