A controllable evaporative micro burner utilizing waste heat of flue gas

A micro-combustion, flue gas waste heat technology, applied in the burner, combustion type, combustion method and other directions, can solve the problem of neglecting the thermal stability of the working wall of the micro-burner and the reasonable working wall temperature, and the increase of the burner surface area to volume ratio , combustion is difficult to operate continuously and efficiently, to achieve the effect of increasing residence time, small relative temperature fluctuation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

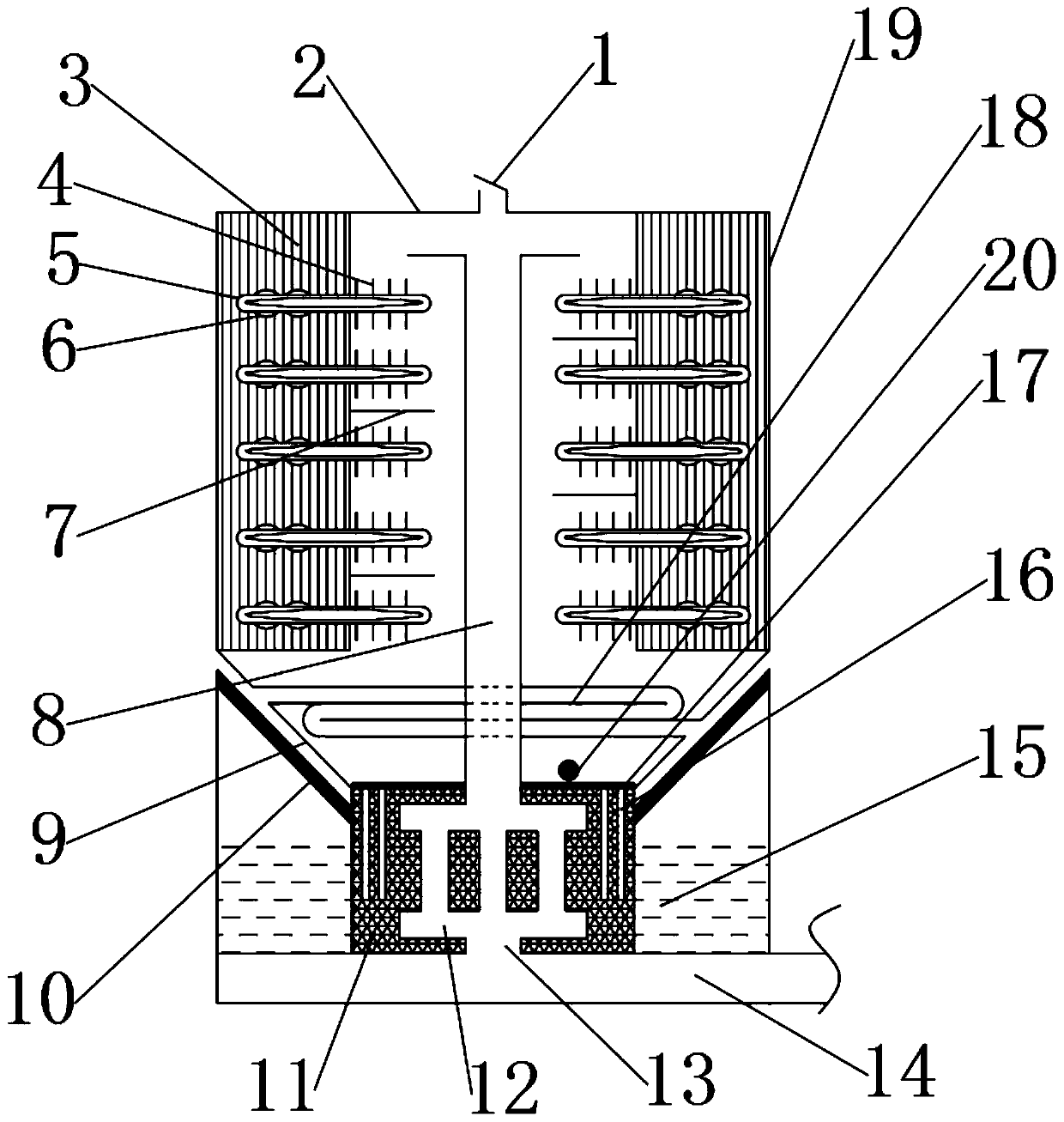

[0025] like figure 1 As shown, a controllable evaporative miniature burner utilizing waste heat of flue gas includes a burner outer cylinder 2, an evaporation core 11 is provided on the inner surface of the lower end of the burner outer cylinder 2, and the evaporation core 11 and the side of the burner outer cylinder 2 An oil tank 15 is formed between the walls, a steam channel 16 is arranged inside the evaporation core 11, a steel wire mesh 17 is fixedly installed on the upper surface of the evaporation core 11, and an igniter 20 is arranged above the steel wire mesh 17;

[0026] A combustion chamber 9 is arranged above the evaporating core 11, and a regenerator 3 is fixedly installed above the combustion chamber 9 close to the inner surface of the side wall of the outer cylinder 2 of the burner. The outer wall of the outer cylinder 2 of the burner corresponding to the regenerator 3 is The working wall surface 19 of the burner, the inside of the regenerator 3 is fixedly inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com