Workshop production scheduling method and system based on resource constraint, terminal and medium

A resource-constrained, workshop-based technology, applied in resources, manufacturing computing systems, data processing applications, etc., can solve problems such as weak emergency response capabilities, high network resources and input costs, and unoptimized output, achieving rapid updates and shortened matching Time, complexity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

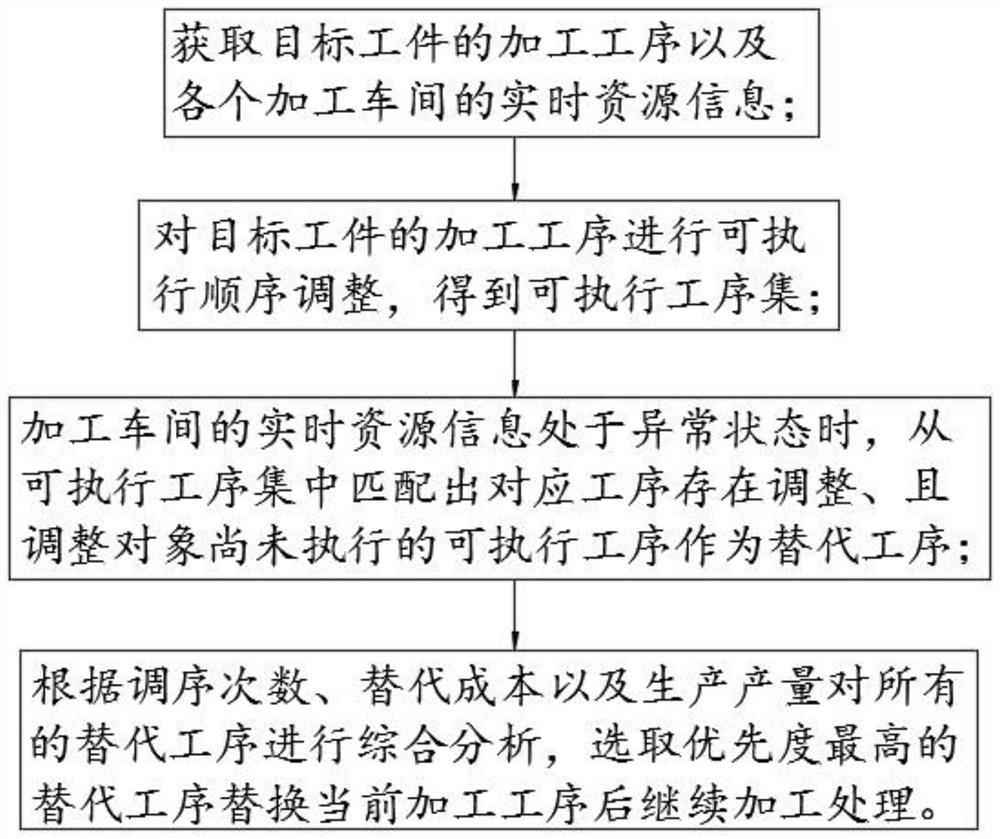

[0047] Embodiment 1: A workshop scheduling method based on resource constraints, such as figure 1 shown, including the following steps:

[0048] S1: Obtain the processing procedure of the target workpiece and the real-time resource information of each processing workshop;

[0049] S2: Adjust the executable sequence of the processing procedures of the target workpiece to obtain an executable procedure set;

[0050] S3: When the real-time resource information of the processing workshop is in an abnormal state, an executable process whose corresponding process has been adjusted and the adjustment object has not been executed is matched from the executable process set as a substitute process;

[0051] S4: Carry out a comprehensive analysis of all the alternative processes according to the number of sequence adjustments, substitution costs and production output, and select the alternative process with the highest priority to replace the current processing process and continue proces...

Embodiment 2

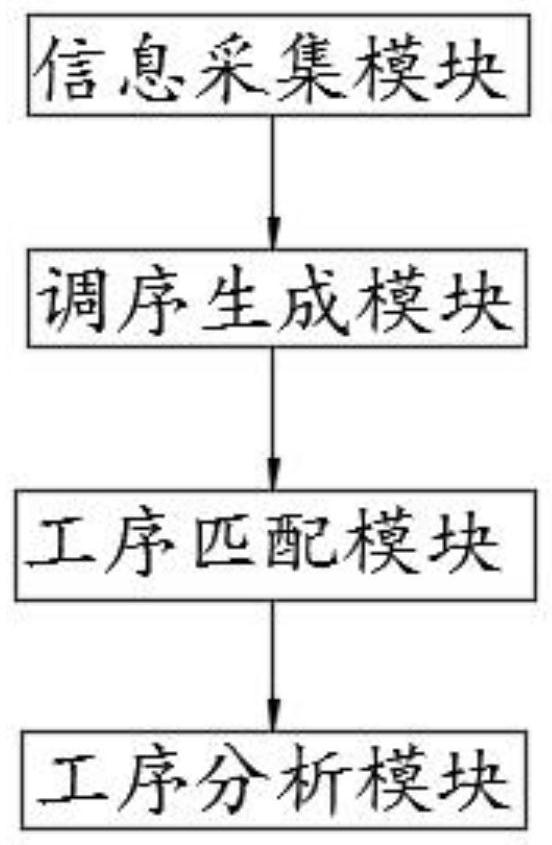

[0066] Embodiment 2: A workshop production scheduling system based on resource constraints, including an information collection module, a sequence generation module, a process matching module and a process analysis module.

[0067] Among them, the information acquisition module is used to acquire the processing procedure of the target workpiece and the real-time resource information of each processing workshop. The sequence generation module is used to adjust the executable sequence of the processing steps of the target workpiece to obtain the executable sequence set. The process matching module is used to match, from the executable process set, an executable process whose corresponding process has been adjusted and the adjustment object has not been executed as a substitute process when the real-time resource information of the processing workshop is in an abnormal state. The process analysis module is used to comprehensively analyze all the substitute processes according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com