Skin bio-printing ink as well as preparation method and application thereof

A bioprinting and ink technology, applied in the fields of biochemical equipment and methods, microorganisms, epidermal cells/skin cells, etc., can solve the problems of difficult batch preparation, complexity, high cost, and achieve the advantages of growth and differentiation, high cell survival rate, and high cost. The effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

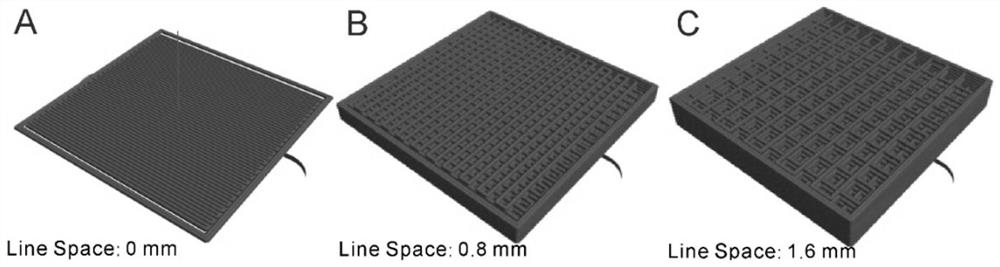

Image

Examples

Embodiment 1

[0047] The preparation of bioprinting ink containing dermal cells includes the following steps:

[0048] (1) After placing sodium alginate powder and gelatin powder under ultraviolet light for 30 minutes, add DMEM complete medium, the final concentration of sodium alginate is 2% (wt%), and the final concentration of gelatin is 10% (wt%) ), and then put the suspension in a 60°C oven for 1 hour to fully dissolve the sodium alginate and gelatin. After the mixture of sodium alginate and gelatin was cooled to room temperature, pasteurize it in a 60°C oven for 1 hour to obtain sodium alginate and Gelatin mixture, placed in a cell incubator for later use;

[0049] (2) Cell culture: First, suck out the original medium in the petri dish with a pipette; then, wash with PBS three times to remove the residual medium, add 2 mL of trypsin (0.25% Trypsin-EDTA) and put it back into the culture Digestion in the incubator for about 3 min. When the cells become round and some cells float, add 2...

Embodiment 2

[0052] The difference between this example and Example 1 is that the dermal layer cells are replaced with epidermal cells.

Embodiment 3

[0060] The difference between this example and Example 1 is that the final concentrations of sodium alginate, gelatin, laminin and their cells in the ink are: 1% (w / v), 10% (w / v), 200 μg / ml and 5×10 6 / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com