Microwave ceramic dielectric material and preparation method thereof

A technology of dielectric materials and microwave ceramics, applied in the field of ceramic dielectric materials, can solve the problems of high loss, high sintering temperature, and low dielectric constant, and achieve the effect of low temperature coefficient of capacitance, high dielectric constant, and excellent microwave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

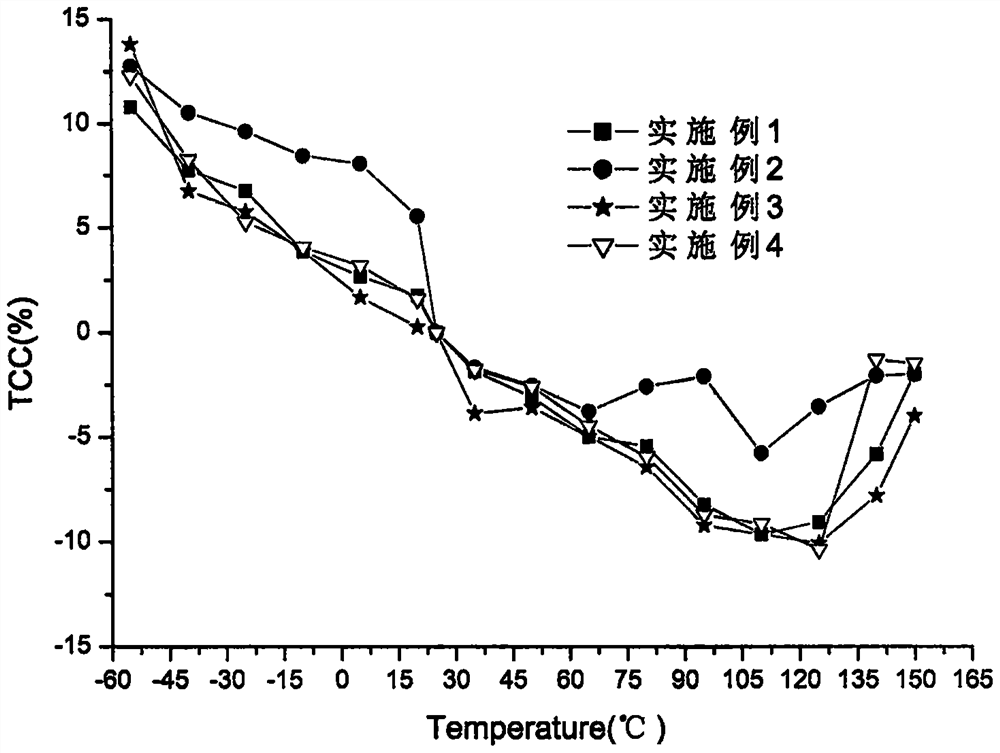

Examples

Embodiment 1

[0023] A microwave ceramic dielectric material, comprising the following raw materials by mass percentage: Li 1.19 Ta 0.81 Ti 0.19 O 3 60%, TiO 2 20%, Ta 2 O 5 5%, Mn 2 O 3 5%, and 10% of glass powder, the glass powder includes the following raw materials by mass percentage: CaF 2 5%, P 2 O 5 25%, CaCO 3 30% and AlF 3 40%.

[0024] Its preparation process is as follows:

[0025] 1) The raw material Li 2 CO 3 , Ta 2 O 5 and TiO 2 According to the general formula Li 1.19 Ta 0.81 Ti 0.19 O 3 , carry out batching, ball mill for 6 hours on a ball mill with a rotational speed of 400r / min, dry at 100°C in a 3.3Gw ordinary oven, and pass 120 holes / cm 2 The sample sieve was heated to 1000°C at a rate of 5°C / min, and kept at 1000°C for 2 hours to obtain frit A.

[0026] 2) Weigh CaF 2 5g, P 2 O 5 25g, CaCO 3 30g and AlF 340g, mixed, melted and water-cooled, ground, and sieved to obtain glass powder B.

[0027] 3) carry out secondary batching, weig...

Embodiment 2

[0032] A microwave ceramic dielectric material, comprising the following raw materials by mass percentage: Li 1.19 Ta 0.81 Ti 0.19 O 3 80%, TiO 2 5%, Ta 2 O 5 5%, Mn 2 O 3 5%, and 5% glass powder, the glass powder includes the following raw materials in mass percentage: CaF 2 40%, P 2 O 5 5%, CaCO 3 30% and AlF 3 25%.

[0033] Its preparation process is as follows:

[0034] 1) The raw material Li 2 CO 3 , Ta 2 O 5 and TiO 2 According to the general formula Li 1.19 Ta 0.81 Ti 0.19 O 3 , carry out batching, ball mill for 7 hours on a ball mill with a rotating speed of 400r / min, dry at 100°C in a 3.3Gw ordinary oven, and pass 200 holes / cm 2 The sample sieve was heated to 1020°C at a rate of 6°C / min, and kept at 1020°C for 3 hours to obtain frit A.

[0035] 2) Weigh CaF 2 40g, P 2 O 5 5g, CaCO 3 30g and AlF 3 25g, mixed, melted and cooled with water, ground and sieved to obtain glass powder B.

[0036] 3) carry out secondary batching, weigh...

Embodiment 3

[0041] A microwave ceramic dielectric material, comprising the following raw materials by mass percentage: Li 1.19 Ta 0.81 Ti 0.19 O 3 70%, TiO 2 10%, Ta 2 O 5 10%, Mn 2 O 3 5%, and 5% glass powder, the glass powder includes the following raw materials in mass percentage: CaF 2 20%, P 2 O 5 30%, CaCO 3 20% and AlF 3 30%.

[0042] Its preparation process is as follows:

[0043] 1) The raw material Li 2 CO 3 , Ta 2 O 5 and TiO 2 According to the general formula Li 1.19 Ta 0.81 Ti 0.19 O 3 , carry out batching, ball mill for 8 hours on a ball mill with a rotational speed of 400r / min, dry at 100°C in a 3.3Gw ordinary oven, and pass 250 holes / cm 2 The sample sieve was heated to 1050°C at a rate of 7°C / min, and kept at 1050°C for 4 hours to obtain frit A.

[0044] 2) Weigh CaF 2 20g, P 2 O 5 30g, CaCO 3 20g and AlF 3 30g, mixed, melted and water-cooled, ground, and sieved to obtain glass powder B.

[0045] 3) carry out secondary batching, wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com