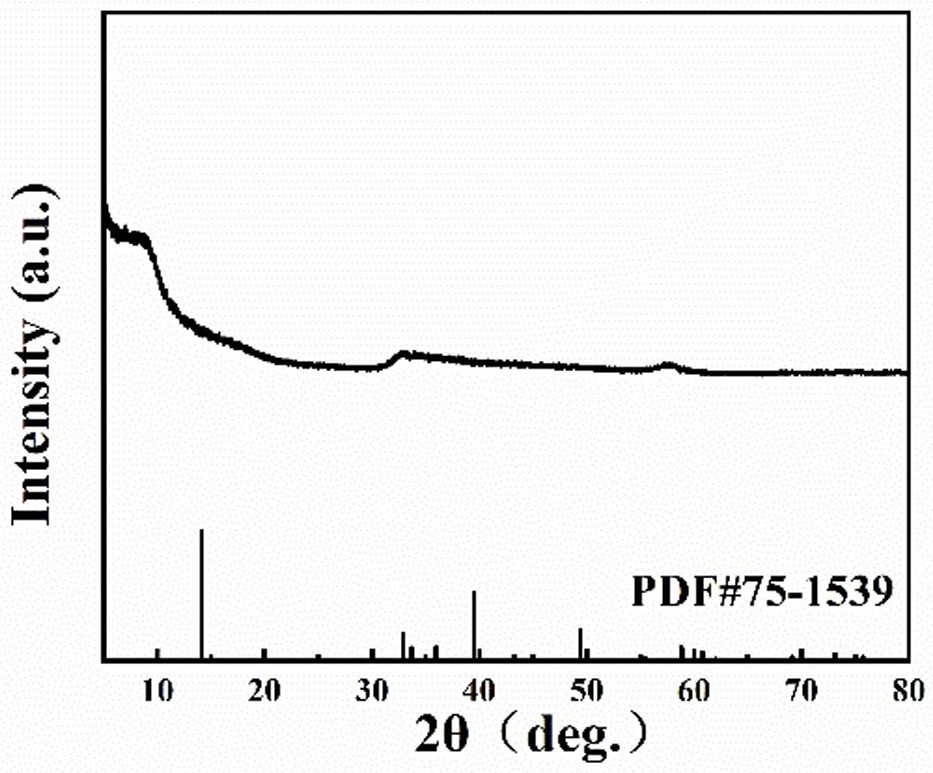

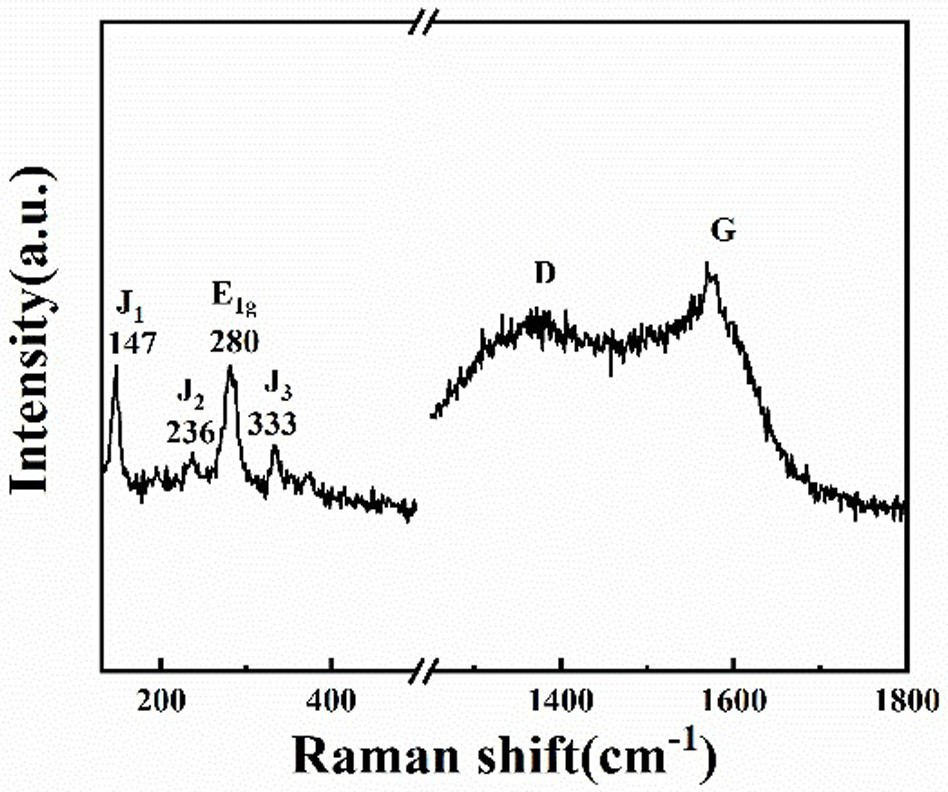

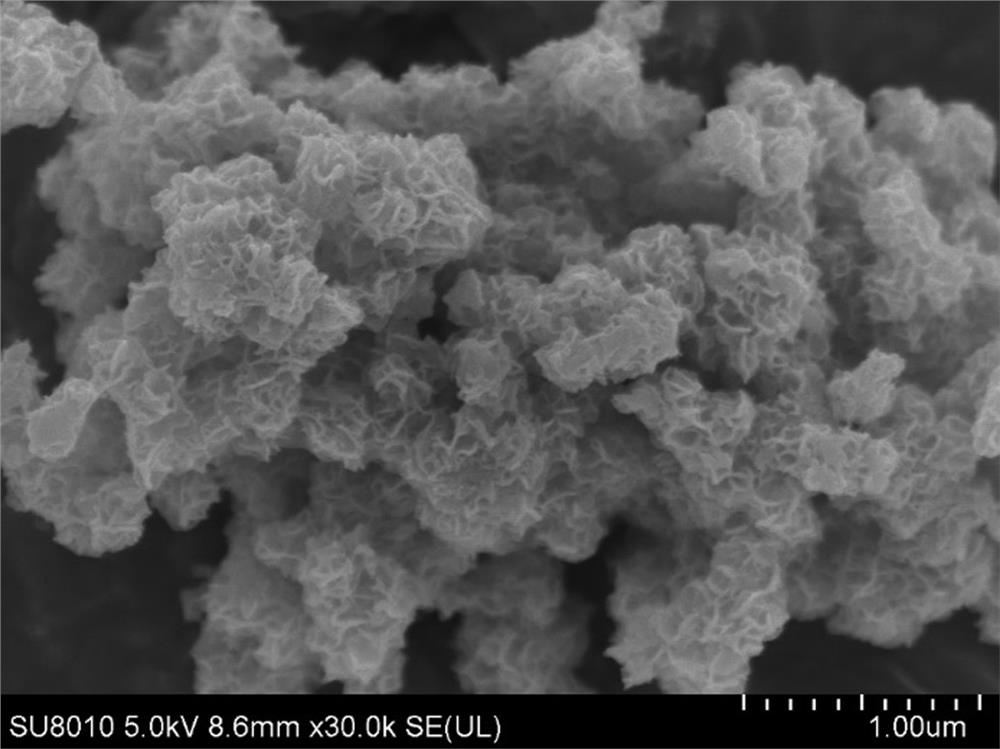

Preparation method of phosphorus-doped amorphous carbon coated 1T-phase molybdenum disulfide/carbon lithium ion battery composite negative electrode material

A lithium-ion battery and amorphous carbon technology, applied in the field of new energy materials for lithium-ion batteries, can solve the problems of low molybdenum disulfide content, unstable structure, and easy agglomeration of products in the 1T phase, and achieve high energy density and electrochemical performance Improve and improve the effect of electron transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Weigh 0.29 g of polyvinyl alcohol, ultrasonically disperse and dissolve it in 40 mL of deionized water, then add 0.14 g of potassium molybdate (concentration of 0.015 M) and 0.18 g of dithiourea (Mo:S = 1:4), and stir until it is Completely dissolved, the molar ratio of molybdenum source and carbon source is 1:11; the mixed solution was transferred to a 50 mL hydrothermal kettle, reacted at 210 ° C for 18 hours, cooled to room temperature, and then centrifuged alternately with deionized water and absolute ethanol Washed 3 times each, then transferred to a 60°C blast oven for drying for 12 hours, and ground to obtain a 1T phase molybdenum disulfide / carbon composite material. Weigh 0.05 g of glufosfamide, 0.1 g of polyvinyl alcohol (the mass ratio of phosphorus source to carbon source is 1:2) and 0.2 g of 1T phase molybdenum disulfide / carbon material (the mass ratio of carbon source to 1T phase molybdenum disulfide / carbon). 1:2) were added to 100 mL of deionized water for ...

Embodiment 2

[0039] Weigh 1.2 g of polyacrylic acid, ultrasonically disperse and dissolve it in 40 mL of deionized water, then add 1.9 g of potassium molybdate (concentration of 0.2 M) and 1.2 g of dithiourea (Mo:S = 1:2), and stir until it is completely Dissolve, the molar ratio of molybdenum source and carbon source is 1:2; transfer the mixed solution into a 50 mL hydrothermal kettle, react at 160 ° C for 36 hours, cool to room temperature, and then alternately centrifuge and wash with deionized water and absolute ethanol 3 times each, and then transferred to a 60° C. blast oven for drying for 12 hours, and then ground to obtain a 1T phase molybdenum disulfide / carbon composite material. Weigh 0.05 g of aluminum phosphoramide, 0.05 g of polyvinyl alcohol (the mass ratio of phosphorus source to carbon source is 1:1) and 0.2 g of 1T phase molybdenum disulfide / carbon material (the mass ratio of carbon source to 1T phase molybdenum disulfide / carbon). 1:4) were added to 100 mL of deionized wat...

Embodiment 3

[0042] Weigh 4.8 g of urea, ultrasonically disperse and dissolve it in 40 mL of deionized water, then add 0.86 g of manganese molybdate (concentration of 0.1 M) and 0.77 g of sulfur powder (Mo:S = 1:6), stir until it is completely dissolved, The molar ratio of molybdenum source and carbon source was 1:20; the mixed solution was transferred to a 50 mL hydrothermal kettle, reacted at 260 °C for 12 hours, cooled to room temperature, and then washed with deionized water and absolute ethanol by alternating centrifugation for 3 times each. time, and then transferred to a 60°C blast oven for drying for 12 hours, and then ground to obtain a 1T phase molybdenum disulfide / carbon composite material. Weigh 0.02 g of benfotiamine, 0.06 g of urea (the mass ratio of phosphorus source to carbon source is 1:3) and 0.2 g of 1T phase molybdenum disulfide / carbon material (the mass ratio of carbon source to 1T phase molybdenum disulfide / carbon is 1:3.3) were added to 100 mL of deionized water for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com