Driving and grading mechanism for all-terrain mobile robot

A mobile robot, all-terrain technology, applied in the field of mobile robots, can solve the problems of no belt tensioning mechanism, low motor output efficiency, difficult braking, etc., to reduce installation accuracy requirements and processing costs, reduce battery energy consumption, The effect of reducing the operating factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means of the present invention, creative features, to achieve the purpose and efficacy easy to understand, the following is further elaborated in the present invention.

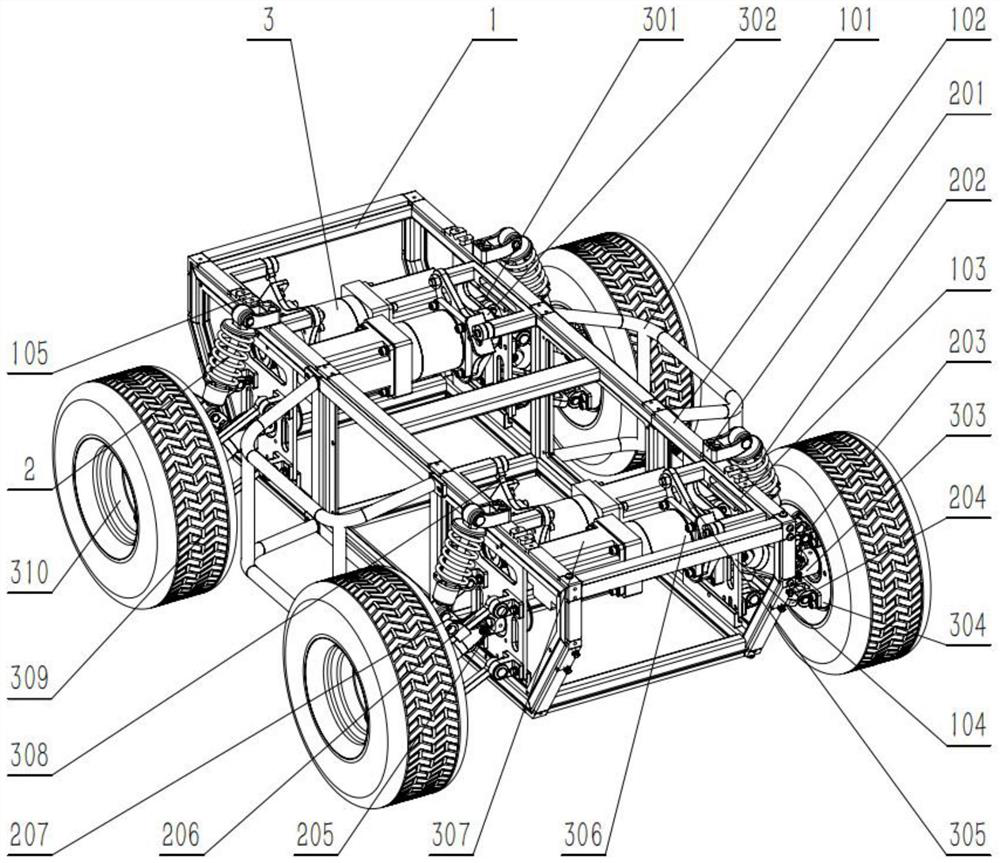

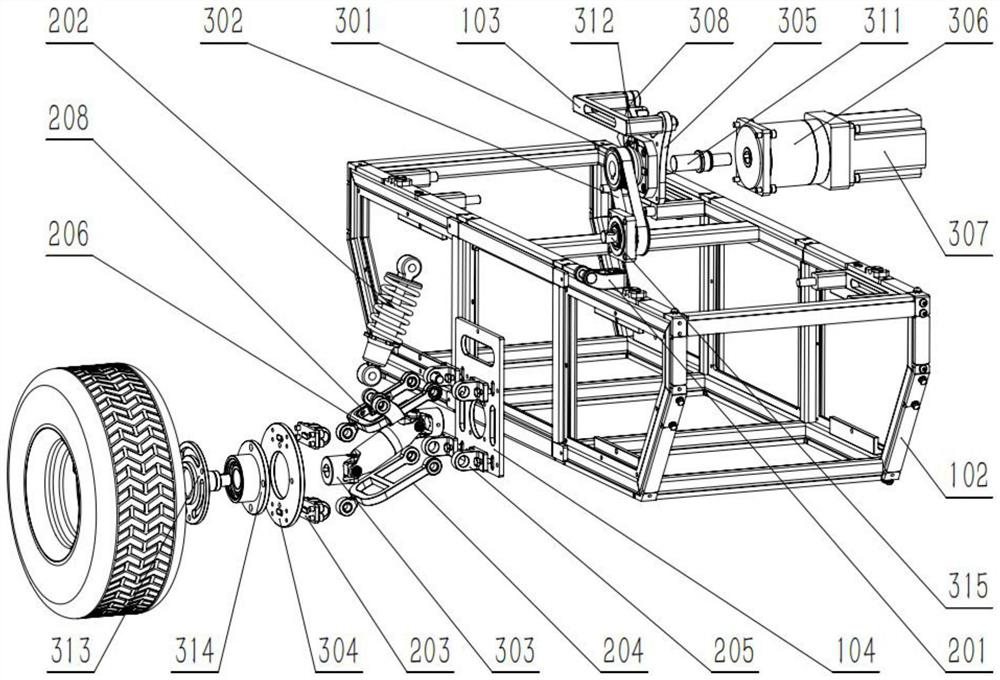

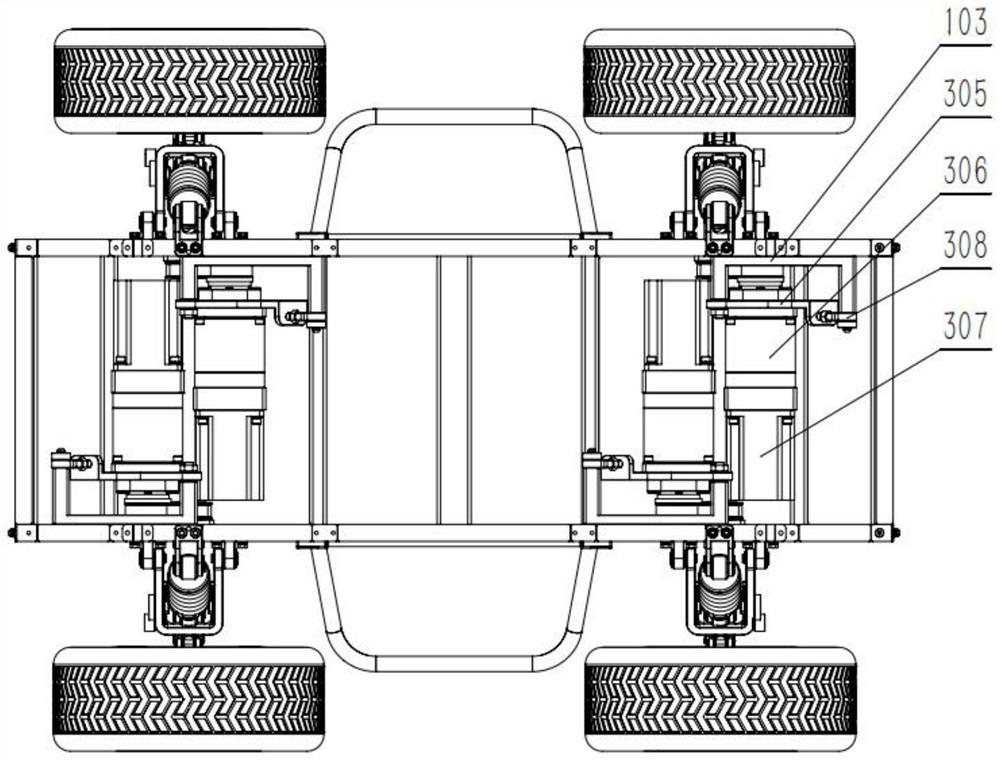

[0029] as Figures 1 through 6 As shown, a drive gearing mechanism for all-terrain mobile robots, including:

[0030] Truss car base assembly 1;

[0031] Gear-type drive unit 3, installed on the truss vehicle base assembly 1, which comprises four sets of power modules arranged and power output using staggered parallel suspension, according to the actual needs to complete the mobile robot driving state and neutral taxiing state switching;

[0032] Double beepton damping unit 2, connected between each set of power modules and the truss car base assembly 1, to enhance the body strength and stability of the mobile robot.

[0033] Specifically, the present invention realizes the separation of the wheel module and the power module by driving the gearing mechanism, reduces the impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com