Method for preparing nano-selenium/attapulgite composite antibacterial material from olive leaf extract

A technology of olive leaf extract and attapulgite, applied in botany equipment and methods, chemicals for biological control, nanotechnology for materials and surface science, etc., to achieve good stability and excellent broad-spectrum antibacterial Activity and antioxidant activity, the green effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

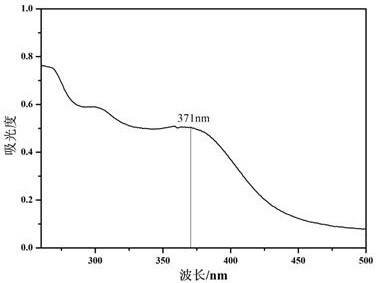

Image

Examples

Embodiment 1

[0033] 1) Add 2.5 g of olive leaf powder to 100 mL of water, extract in a water bath at 65°C for 1 hour, and filter to obtain a solution of olive leaf extract; 2) Disperse 0.4 g of attapulgite into 50 mL of olive leaf extract solution under stirring, and ultrasonically treat it Then, 50 mL of sodium selenite solution was added dropwise to obtain a precursor mixture with a concentration of 0.005mol / L of sodium selenite; 3) The above precursor mixture was placed in a shaker at 100 rpm and reacted at room temperature for 48 hours; the obtained product was centrifuged and washed three times, vacuum After drying at 35℃ for 10h, the nano-selenium / attapulgite composite antibacterial material was obtained.

Embodiment 2

[0035] 1) Add 5 g of olive leaf powder to 100 mL of water, extract in a water bath at 70°C for 1 hour, and filter to obtain a solution of olive leaf extract; 2) Disperse 0.45 g of attapulgite into 80 mL of olive leaf extract solution under stirring, and after ultrasonic treatment 50 mL of sodium selenite solution was added dropwise to obtain a precursor mixture with a concentration of 0.01 mol / L of sodium selenite; 3) The above precursor mixture was placed in a shaker at 130 rpm and reacted at room temperature for 24 hours; the obtained product was centrifuged and washed three times, and vacuum 40 After drying at ℃ for 12 h, the nano-selenium / attapulgite composite antibacterial material was obtained.

Embodiment 3

[0037] 1) Add 10 g of olive leaf powder to 100 mL of water, extract in a water bath at 70°C for 1 hour, and filter to obtain a solution of olive leaf extract; 2) Disperse 0.65 g of attapulgite into 100 mL of olive leaf extract solution under stirring, and after ultrasonic treatment 50 mL of sodium selenite solution was added dropwise to obtain a precursor mixture with a concentration of 0.02mol / L of sodium selenite; 3) The above precursor mixture was placed in a shaker at 150 rpm and reacted at room temperature for 12 h; the obtained product was centrifuged and washed three times, and vacuum 40 After drying at ℃ for 13 h, the nano-selenium / attapulgite composite antibacterial material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com