Polyphenol chitosan oligosaccharide compound as well as preparation method and application thereof

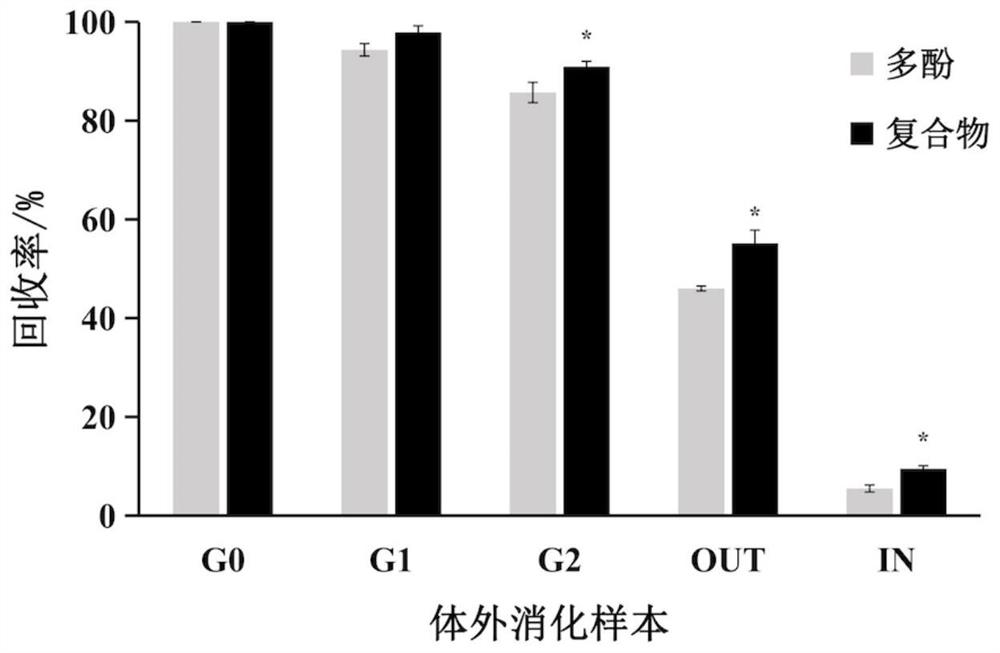

A technology of chitosan oligosaccharides and complexes, which is applied in the field of polyphenol chitosan oligosaccharides complexes and its preparation, can solve the problems of application limitations, polyphenols unstable and easy to decompose, etc., and achieve the improvement of anti-oxidation and the dissolution of polyphenols rate and antioxidant activity of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of polyphenol-chitosan oligosaccharide complex, the preparation method is as follows:

[0032] (1) Using buckwheat bran polyphenols, chitosan oligosaccharides (molecular weight 980Da) and naked oat flour as raw materials; (2) Enzymatic hydrolysis of buckwheat with 0.5% (unspecified in this application, all refer to mass fraction) glucoamylase Bran, incubate at 57.5°C for 190 min and then boil to inactivate the enzymes; (3) Extract polyphenols from buckwheat bran with ethanol, mix with chitosan oligosaccharide solution in an equal volume at a mass ratio of 1:1, shake on a vortex shaker for 10 min, and the mixed solution After centrifugation at 1,000 × g for 10 min, the supernatant was taken for freeze-drying to obtain the polyphenol-chitosan-oligosaccharide complex;

Embodiment 2

[0033] Example 2: A polyphenol-chitooligosaccharide complex comprising polyphenol extraction and chitooligosaccharide. The preparation method is as follows:

[0034] (1) Using buckwheat bran polyphenols, chitosan oligosaccharides (molecular weight: 980 Da) and naked oat flour as raw materials; (2) Enzymatic hydrolysis of buckwheat bran with 1.5% protease, culturing at 57.5°C for 190 min, and boiling to kill the enzymes; (3) ) Extract buckwheat bran polyphenols with ethanol, mix with chitosan oligosaccharide in a mass ratio of 1:1, mix the two in equal volumes, shake on a vortex shaker for 10 min, and centrifuge the mixture at 1,000 × g for 10 min, and then take the supernatant for freezing. drying to obtain polyphenol chitosan oligosaccharide complex;

Embodiment 3

[0035] Example 3: A polyphenol-chitooligosaccharide complex comprising polyphenol extraction and chitooligosaccharide. The preparation method is as follows:

[0036] (1) Using buckwheat bran polyphenols, chitosan oligosaccharides (molecular weight 980Da) and naked oat flour as raw materials; (2) Enzymatic hydrolysis of buckwheat bran with 1.5% cellulase, culturing at 57.5°C for 190 min, and boiling to inactivate the enzymes; (3) Extract buckwheat bran polyphenols with ethanol, mix with chitosan oligosaccharide in a mass ratio of 1:1, mix the two in equal volumes, shake on a vortex shaker for 10 minutes, and centrifuge the mixture at 1,000 × g for 10 minutes, and then take the supernatant freeze-drying to obtain polyphenol chitosan oligosaccharide complex;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com